What Is a Major Load Air Conditioning System and Why It Matters

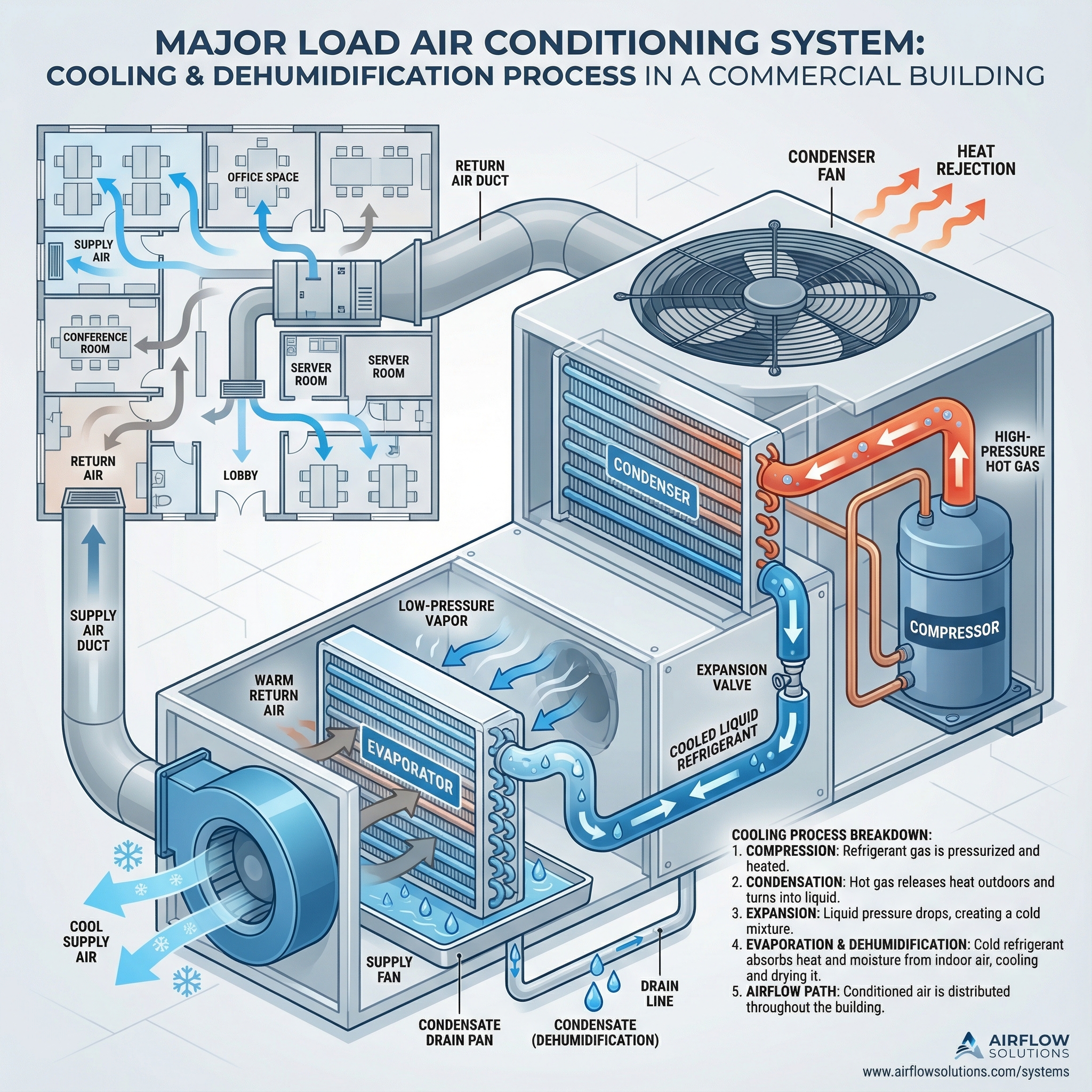

The major load air conditioning system is the primary, high capacity unit that carries the bulk of a home or building's cooling during the hottest, stickiest hours. Think of it as the main engine that does the heavy lifting at peak conditions. In practice, sizing that major load comes from a real heat gain picture of the structure, not just square footage or rule of thumb guesses.

- Solar heat gain through windows and walls

- Air leakage and infiltration

- Insulation quality and attic conditions

- Internal gains from people, lighting, and appliances

- Moisture removal needs from high humidity

Getting the equipment capacity matched to the true load affects comfort, energy use, and equipment life. Oversized systems short cycle, leave humidity behind, and waste power. Undersized systems run constantly, struggle to pull temperatures down, and create hot and cold spots. When capacity is right, and basics like clean filters, correct airflow, and tuned components are maintained, the system runs more efficiently, experiences fewer breakdowns, and tends to last longer. That alignment is the foundation for steady comfort and predictable utility bills.

What a �Major Load' System Actually Is: Simple Definition and Typical Types

A major load air conditioning system serves large, high-occupancy, or high-gain spaces, providing substantial capacity with stable airflow and humidity control across many rooms or zones. It is selected to handle peak sensible and latent loads without short cycling, and to integrate cleanly with building ductwork or multi-zone distribution.

- Large split systems: ducted air handler with multi-stage or inverter outdoor unit, typically 5 to 25 tons.

- Packaged rooftop or ground units: gas-electric or heat pump configurations, 3 to 25 tons.

- VRF or VRV multi-zone heat pump systems for diversified floor plans and long line lengths.

- Chilled water air handlers paired with a chiller for light commercial or estate-size homes.

- Water-source heat pumps on boiler-tower or geothermal loops for multi-unit buildings.

- High-static ducted systems designed for extensive duct runs and zoning.

Why Proper Design and Right Sizing Matter for Major Load Systems

Performance and value in major-load cooling come from two places: smart equipment design and a system that actually matches your building's cooling and dehumidification needs. One component that quietly drives lifecycle cost is the condenser fan motor. Choosing a high efficiency motor improves outdoor heat rejection, trims electrical use, and reduces wear over time. Established brands with long manufacturing track records tend to deliver that efficiency and reliability, turning your purchase into long term comfort rather than a bin of parts. In our experience at Budget Heating (BudgetHeating.com), looking at the AC load breakdown helps pinpoint which components move the needle on comfort and energy.

Right sizing is simple in principle and critical in practice. Think of capacity like shoe size: too big slips, too small pinches. Oversized units short cycle, waste energy, and miss humidity control. Undersized units run continuously, struggle to hit setpoint, and still feel clammy. Professional load calculations, not rules of thumb, are how you land on the sweet spot.

- Steadier temperatures with fewer swings

- Better humidity control in real-world conditions

- Quieter operation and less component stress

- Lower lifecycle costs when paired with efficient parts

A well sized, well designed system pays you back every day in comfort and operating savings.

Common Mistakes and Tradeoffs: When a Major Load System Isn't the Right Choice

From decades of field work, we see habits that quietly erode comfort and efficiency:

- Closing supply vents in unused rooms does not save energy. It raises duct static pressure, can drive leakage, and strains the blower. Keep airflow balanced, or use real zoning when rooms need different settings.

- Bigger is not better. Oversized units short cycle, miss dehumidification, cause temperature swings, waste power, and wear out faster. Capacity should be based on a proper load calculation for the home.

- Annual filter changes are too infrequent. Dirty filters choke airflow and degrade indoor air quality. Most homes need replacements every 1 to 3 months, depending on filter type, pets, and dust.

When is a major-load central system a poor fit?

- Tight, efficient homes or mild climates where humidity control dominates. Consider a smaller variable-speed system or a dedicated dehumidifier paired with modest cooling capacity.

- Leaky or undersized ducts. Fix ducts first, or use ductless mini-split zones to bypass problem runs.

- Intermittently used spaces like additions or bonus rooms. Targeted zoning or room-by-room ductless typically improves comfort and lowers run costs.

Maintenance, Safety, and What Homeowners Can and Should Do Themselves

From 30+ years in HVAC, we draw a simple line: owners handle light upkeep, licensed techs handle electrical, refrigerant, gas, and complex mechanics.

- Replace or clean filters with power off: 1 to 3 months for 1 inch, 3 to 6 for thicker media.

- Keep the outdoor condenser clear, 2 to 3 feet on sides and an open top, remove leaves and vegetation.

- Keep vents open and vacuum grilles, verify thermostat mode, setpoints, and batteries.

- Check the condensate drain, flush with mild vinegar if accessible. Use basic PPE, ladder safety. Shut down for smoke, burning smells, or odd noises. Do not bypass safeties.

Call a licensed technician for electrical faults, any refrigerant work including charging or leak repair, compressors or motors, coils or expansion devices, furnaces or venting, carbon monoxide alarms, and any installation or permitted change. Scheduled professional service protects efficiency and service life.

Homeowner & Facility Checklist: How to Decide If You Need a Major Load System

From decades of field installs and commissioning, this is the practical checklist we use to confirm when a major load AC or heat pump is justified and how to get it specified correctly.

- Define your climate: hot humid, hot dry, cold, or mixed. Hot humid, prioritize latent capacity and consider supplemental dehumidification. Cold with humid summers, consider variable capacity or cold climate heat pumps sized between heating and cooling needs, plus a summer humidity plan. Hot dry, prioritize peak dry heat cooling capacity.

- Insist on a Manual J room by room load. No tons per square foot shortcuts.

- Review humidity: confirm sensible and latent capacities at design conditions. Target 40 to 60 percent RH without overcooling, add standalone dehumidification if needed.

- Verify capacity at cooling and heating design temperatures. Define the outdoor temperature where backup heat engages.

- Prefer variable speed or variable capacity in challenging climates to reduce short cycling and improve moisture control.

- Prepare ducts: seal and insulate, ensure adequate returns and correct register sizes and locations. Have airflow set and measured, CFM per ton and total external static pressure.

- Compare SEER2, EER2, HSPF2 as applicable, and consider IAQ upgrades like MERV 11 to 13 filtration.

- Choose controls that manage dehumidification and staging. Avoid continuous fan in humid seasons. Set RH targets near 40 to 60 percent.

- Commissioning must document refrigerant charge, measured airflow, static pressure, condensate drain and safety shutoff, duct leakage test, AHRI matched pairing, and startup performance.

- Require deliverables: full Manual J, Manual S, Manual D, model numbers and ratings, latent strategy, duct modifications and returns, backup heat plan, warranties.

- Maintain: replace filters every 1 to 3 months, clear the outdoor unit, flush condensate drains, schedule annual service including humidity checks.

- Red flags: sizing by square footage, dismissing Manual J, S, D, oversizing just in case, ignoring duct sealing or humidity control.

- Ask about utility or state incentives for high efficiency or cold climate heat pumps and what documents are required.

Regulations, Regional Differences, and the Refrigerant Transition You Need to Know

Regional climate and federal rules shape what you can install and how you size it. DOE's 2023 update moved to SEER2, EER2, and HSPF2 and raised minimums: Northern states must meet the equivalent of 14 SEER, about 13.4 SEER2. In the Southeast and Southwest, units under 45,000 Btu/h must meet roughly 15 SEER, about 14.3 SEER2, and 45,000 Btu/h and up must meet about 14.5 SEER, about 13.8 SEER2. Hot dry markets add EER2 thresholds to protect full load efficiency. Local permitting often requires proof of compliance.

Climate then drives design priorities. Hot humid regions need right sized cooling with strong latent capacity, often variable capacity or added dehumidification. Cold or mixed humid regions may size heat pumps toward the heating load, favoring cold climate or variable capacity units with limited backup. Hot dry areas emphasize full load EER/EER2, sometimes evaporative cooling. In our experience at Budget Heating (BudgetHeating.com), the AIM Act is moving new residential and light commercial systems from R-410A to lower GWP A2Ls like R-32 and R-454B for 2025 manufacture dates, and updated IMC/IRC 2024, IECC 2021/2024, and ASHRAE 90.1 enable A2Ls and reinforce proper Manual J, S, D design. IRA incentives further favor high efficiency variable speed systems.

Efficiency Metrics and Performance: SEER, EER, Part Load Behavior and What They Mean

SEER measures seasonal cooling output per unit of electricity. Higher SEER means less energy for the same comfort. We still encounter 8 to 10 SEER units, while current models start around 14 to 16, with premium systems in the high teens to mid 20s, up to SEER 25. Upgrading 10 to 16 SEER cuts AC energy about 38%, and 14 to 16 saves roughly 10 to 15%.

In 2023 ratings shifted to SEER2. Minimums are region specific: North 13.4 SEER2, about 14 SEER. Southeast and Southwest 14.3 SEER2 under 45,000 Btu/h, 13.8 SEER2 at or above 45,000. Some configurations must also meet EER2 for full load in hot, dry climates. SEER2 runs about 5% lower, so compare within the same metric.

Part load operation is where efficiency and comfort are won. Variable speed or multi stage compressors act like a dimmer switch, matching output to the home's need, reducing cycling, smoothing temperatures, improving humidity control, and trimming operating cost.

Costs, Savings and Payback: What to Expect (and What's Missing)

Specific cost and savings ranges are not available here. In our experience, payback varies most with climate, local utility rates, equipment size and efficiency, installation quality, duct condition, and available rebates or tax credits. Home envelope, thermostat habits, and run time matter too. Gather written apples to apples quotes, verify incentives with your utility or state, and compare total installed cost to projected annual bill reduction.

Key Takeaways: How to Assess, Specify and Maintain a Major Load AC System

Your major-load AC is the building's cooling backbone, typically a central split, rooftop unit, VRF ductless network, or in larger plants, a chiller. The heart of the system is a coordinated set of components: compressor or chiller, condenser, evaporator or air handler, pumps or blowers, distribution ductwork or piping, and the controls that stage, zone, and dehumidify for steady comfort.

Applications span homes to light industrial. Priorities stay consistent: verify heat gains and losses, limit duct or piping losses and infiltration, match equipment and controls to codes and climate, and plan zoning, humidity control, and ventilation for comfort and low operating cost. Professional design and preventive care protect performance.

Comparing options or replacing a tired system? Our team can size, specify, and ship at wholesale pricing. With 30+ years in HVAC and U.S.-based tech support, you get practical answers fast.

- Get a Custom Quote, load check and matched equipment list

- Talk to Our Team, U.S.-based phone support and design guidance

- Shop Central Systems, AC, heat pumps, and ductless mini splits, free shipping on many models, Affirm financing available