Why Two-Stage Furnaces Matter for Comfort and Efficiency

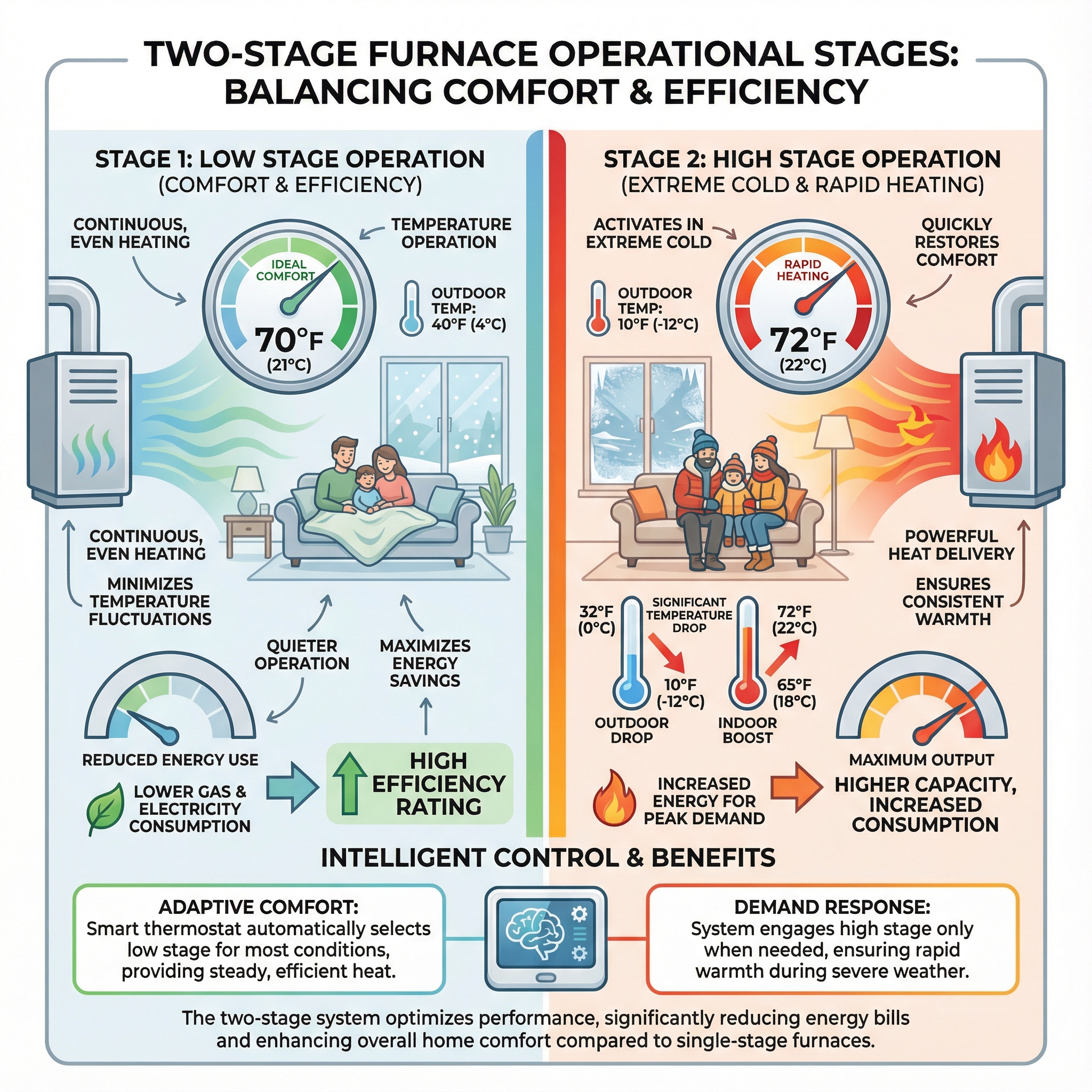

Two-stage furnaces heat at two output levels: a lower comfort stage for everyday demand and a high stage that steps in during very cold weather. In our experience, they spend most of their time in the lower stage, delivering gentler, longer heating cycles instead of the stop and go bursts common with single-stage units. That steadier approach helps cut temperature swings and short cycling, so rooms feel more consistently warm.

Think of it like riding a two-speed bike. You use the easy gear for most of the ride, then shift up only on the hill. Staging works the same way. The furnace modulates between low and high to match the load, which supports better air mixing and filtration when paired with compatible controls and blowers. If you are comparing systems, understanding this low versus high stage operation sets the baseline for comfort expectations and how the equipment will behave day to day.

How Two-Stage Furnaces Work: The Practical Basics

We work with two-stage furnaces that use a two-position gas valve and simple staging logic. When the thermostat calls for heat, the control board starts in low stage, roughly 60 to 70 percent of full capacity. For routine calls, that lower output is enough, so the unit stays there. If the home needs more heat, such as a larger temperature pull, the controls shift the gas valve to high stage, delivering full capacity.

This approach influences run time. Low-stage operation stretches cycles and trims short cycling, so temperatures drift less between on and off periods. Longer, steadier runs also push more total air through the filters, which improves overall capture compared with quick blasts. Think of it like a light with two brightness settings. Most of the time the lower setting keeps the room comfortable, and the higher setting is reserved for when conditions truly demand it.

Two-Stage vs Single-Stage vs Variable-Speed: How They Differ

Single-stage delivers full output whenever it fires. Two-stage steps between low and high heat. Variable-speed refers to the blower motor, which modulates airflow continuously, like a dimmer switch, to match the load. Two-stage controls burner output, variable-speed controls airflow, and they are not the same. Single-stage is simplest, variable-speed airflow can lower noise and even out temperatures.

Myths to drop: longer run times waste energy. Low-stage cycles often reduce starts and improve comfort. Cranking the thermostat does not heat faster, it just overshoots. Closing vents rarely saves money, it raises static pressure and can stress components. Two-stage still needs correct sizing and regular service. Wiring expectations matter: two-stage heat generally needs W1 and W2 with a compatible thermostat, while many variable-speed blowers are managed by the furnace control board rather than extra thermostat wires.

Energy Savings & Cost Analysis: Calculating ROI for a Two-Stage Furnace

Two-stage furnaces cost more up front than entry-level single-stage units, yet less than fully modulating systems. A real homeowner example: winter gas use dropped from about 950 therms to 820 therms, trimming annual bills from roughly $1,330 to $1,150. That is about $180 saved, or 13 to 15 percent. In our experience at Budget Heating (BudgetHeating.com), results like this show up when the equipment is sized correctly and ducts are tight.

Payback is simple: take the price difference between two-stage and single-stage, then divide by your expected yearly savings. What drives that number are local fuel prices, climate and heating hours, the home's envelope and air sealing, proper sizing and duct design, thermostat strategy, and the quality of installation. Two-stage operation often runs longer on a low stage, keeping steadier heat with less wasted fuel, which is where the ROI comes from.

Comparing Two-Stage Furnaces to Other Efficient Heaters (AFUE, SEER2 and System Pairing)

AFUE is the seasonal heating efficiency of a furnace. A 95 percent AFUE unit turns about 95 percent of fuel into heat, so roughly 5 percent is lost. Two-stage furnaces run at a lower and a higher input, like a dimmer switch instead of just on or off. They are sold as about 80 percent non-condensing models and as condensing designs in the 90 to 98 percent AFUE range.

Cooling efficiency uses SEER and the newer SEER2. SEER2 uses updated test procedures that yield lower numbers than legacy SEER, even when systems perform similarly. From years of field work, we see two-stage furnaces pair best with variable-speed ECM blowers. Slower airflow during low fire improves heat transfer, evens room temperatures, and enhances filtration. The same motor benefits cooling, aiding coil performance and dehumidification. When matched with high SEER2 outdoor equipment, year-round operating costs drop.

Key Benefits: Comfort, Humidity Control, Noise Reduction, and Efficiency

Two-stage furnaces spend most of their time in low stage, which keeps rooms closer to the setpoint and avoids the hot-then-cool rollercoaster some homes feel with single-stage heat. The longer, gentler cycles are key. With more minutes of steady airflow, indoor air passes through the filter more often each hour, which improves capture of dust and allergens, and the steadier heat helps indoor humidity stay more consistent.

Because low stage reduces on-off cycling, seasonal energy performance is typically better than comparable single-stage units and mechanical wear is reduced. Low-stage operation is also noticeably quieter, so conversations and sleep are less disturbed. Many homeowners find two-stage offers a strong value between basic single-stage and premium fully modulating models.

To realize these benefits, correct sizing is essential, along with a compatible thermostat. Pairing with a variable-speed or ECM blower and tight, well-balanced ductwork helps maximize comfort, airflow, and filtration. In our field experience, the combination of long low-stage run time and smooth airflow is what delivers the stable temperatures, cleaner air, and calmer acoustics people expect from a two-stage system.

High-Efficiency Gas Furnaces and Two-Stage Technology: Policy & Regional Considerations

Starting in 2028, the DOE 95% AFUE minimum for many residential non-weatherized gas furnaces will phase out most 80% models. That shifts the market toward condensing platforms, where two-stage operation is common at roughly 95 to 97% AFUE. Homeowners should expect available models to tighten in some categories and a stronger emphasis on high-efficiency pairings.

Regional context matters. Cooling-side SEER2 rules can affect system pairing, incentives, and which models are offered locally. Local air-quality policies, low-NOx requirements, altitude limitations, or gas-connection ordinances may narrow choices further or steer buyers toward specific two-stage designs. In colder and mixed climates, two-stage control delivers clear comfort gains, while milder regions still see steadier temperatures. We plan selections around these layers of policy and climate so the chosen furnace aligns with both code and comfort.

Potential Drawbacks and Limits: When Two-Stage Furnaces Aren't the Best Fit

Two-stage furnaces improve comfort, but they are not universal. In our field experience, these situations often point to other options:

- Strict budgets: two-stage units cost more upfront than basic single-stage. The gains depend on correct sizing, a compatible two-stage thermostat, and a quality install.

- Very cold climates or where ultra precise capacity control matters: a fully modulating furnace delivers finer output steps and steadier supply temperatures, at a higher price.

- Poor ductwork or oversizing: leaky, undersized, or imbalanced ducts, or a too-large furnace, can erase two-stage advantages, leading to persistent hot and cold spots or short cycling.

- Small, simple layouts with short duct runs: benefits may be modest versus a properly sized single-stage.

Alternatives to consider include fully modulating gas systems for peak comfort, or a dual fuel approach, an electric heat pump for most hours with gas backup for extremes. In mixed climates this can trim utility costs while maintaining capacity in cold snaps.

How to Choose the Right Two-Stage Furnace: Sizing, Controls, and Compatibility

Use this practical checklist to get the comfort and savings you expect.

- Set climate and comfort goals, noise and humidity included.

- Require a Manual J room by room heat load.

- Pair the two-stage gas valve with a variable-speed ECM blower.

- Pick AFUE that fits your climate and fuel price.

- Verify thermostat W1 and W2 support, match staging logic.

- Check ducts with Manual D, static pressure and returns.

- Plan venting, gas sizing, shutoff, drip leg, condensate.

- Integrate humidity and IAQ, filtration and fresh air.

- Choose location for access and low noise, add pads.

- Demand commissioning, set blower profiles, verify temperature rise and static, adjust gas, run combustion and CO tests. In our experience at Budget Heating (BudgetHeating.com), missed checks drive most comfort issues.

- Compare total value, warranties, and installer reputation.

- Pull permits and secure available rebates.

- Plan annual maintenance to keep staging and airflow right.

- Consider future integration, heat pump backup or smart controls.

Next Steps: Maintenance, Decision Checklist, and When to Call an HVAC Pro

Two-stage systems shine by keeping temperatures steady, trimming noise, and easing wear through longer low-stage run time. To protect those benefits, handle the simple upkeep: check filters monthly and replace every 1 to 3 months, keep supply and return vents clear, visually inspect outdoor condensing-unit terminations, verify thermostat schedules and modes, test CO and smoke detectors, and watch for warning signs like odd odors, water around equipment, or error codes.

Call a pro for anything involving gas or combustion, advanced electrical or control setup, staging configuration, condensate or duct changes, and any refrigeration or cooling work. Book at least a yearly tune with combustion analysis, staging verification, airflow measurements, and written findings. Choosing size and setup can feel like a lot, and it is worth getting right. Our team has 30+ years in HVAC and U.S.-based phone support, so we can help you select, size, and plan installation with confidence.

- Get a Custom Quote

- Talk to Our Team by phone for sizing and compatibility

- Shop Two-Stage Furnaces

- Explore financing with Affirm and fast shipping from our PA and TX warehouses