The Tech Behind Electric HVAC Most People Miss: A Quick Primer

Many people assume electrifying HVAC is a simple on/off swap. In reality, modern electric systems are built on a stack of variable-speed electronics and software that decide how your space feels, what your utility bill looks like, the indoor air quality you breathe, and how long the equipment lasts. Successful electrification depends as much on controls, system integration, and commissioning as on the heat source itself.

The core idea is heat transfer, not heat generation. A heat pump works like a refrigerator in reverse: it moves heat from one place to another. Because it is moving energy instead of creating it with resistance coils or flames, it can deliver two to four units of heat for every unit of electricity it uses under typical conditions. That basic efficiency advantage is unlocked by inverters, sensors, and smart airflow management that match output to the building. Proper setup, duct design, and tuning let the controls coordinate defrost, humidity, and staging so comfort stays even and energy use stays low.

Why Electric HVAC Is More Than Just 'Electric Heat': Efficiency and Comfort That Goes Beyond the Label

Switching to electric HVAC is not simply swapping fuels; a heat pump delivers two to four times more heat per kilowatt-hour than electric resistance, so the utility bill reflects that multiplier. Modern inverter systems behave like a dimmer switch, not a light switch. They run longer at low speed, holding steadier room temperatures and wringing out more humidity, which feels more comfortable while using less energy. In the field, we see that real performance depends on correct sizing, duct design, and installation quality. Nameplate SEER or SEER2 matters, but it is only part of the story.

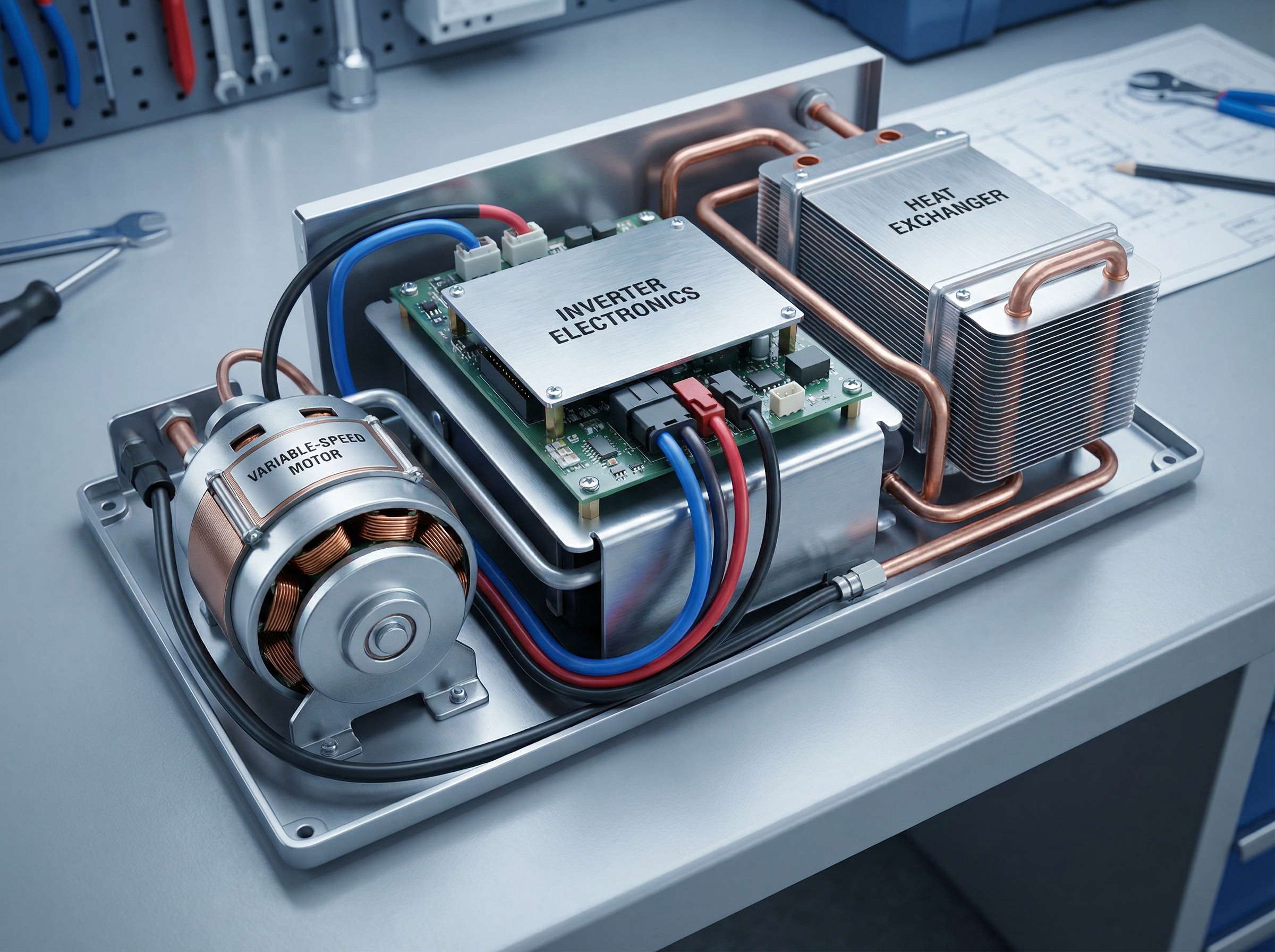

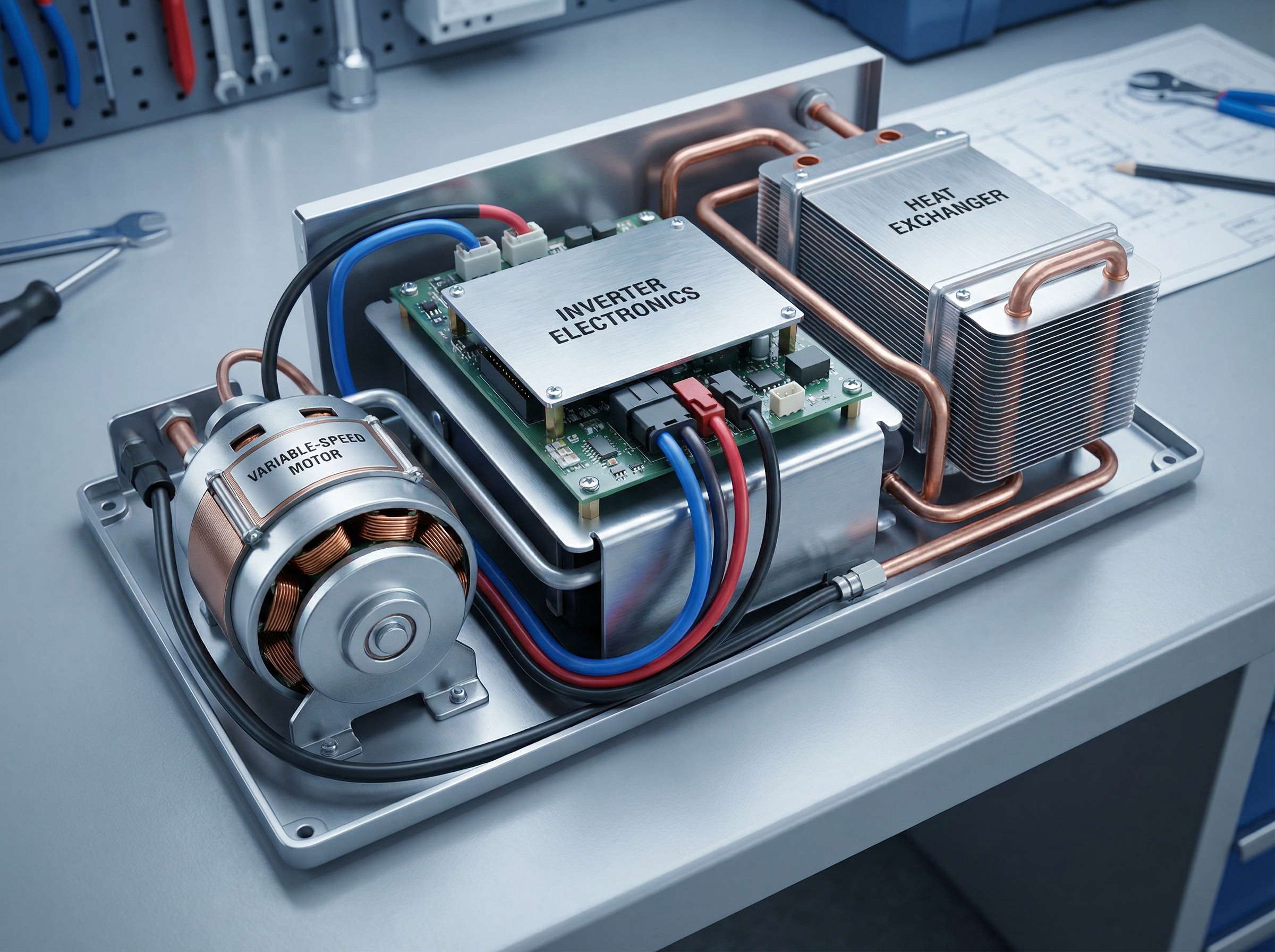

Core Components Most Homeowners Never Notice: Variable-Speed Motors, Pumps and the Inverter Stack

Modern comfort is built on parts you rarely notice. The inverter electronics and variable-speed hardware decide how gently and efficiently a system moves heat, not just whether it is on or off.

- Inverter-driven compressors: Instead of short on and off bursts, the compressor modulates capacity to match the load. That reduces temperature swings, cuts start-up current spikes, and boosts part-load efficiency. Avoiding hard starts and rapid cycling also lowers mechanical stress, which helps equipment last longer. When the inverter coordinates compressor speed with fan speed and the expansion device, coil temperatures and pressure ratios stay in the sweet spot, so you get more heating or cooling per kWh.

- ECM blowers and fans: Electronically commutated motors give precise airflow control and use less electricity than single-speed motors. Fine airflow adjustments help the system hold target coil conditions, which supports efficient operation and more even room temperatures.

- Variable-speed pumps and fans: Matching flow to the real-time load trims part-load losses compared with fixed-speed components. This coordinated approach helps keep coil performance and pressure ratios optimal, increasing useful output per kWh and reducing wear by avoiding abrupt starts or stops.

In our field work, the difference feels like replacing a simple light switch with a dimmer. The system settles into exactly what the home needs, runs steadily at low speed instead of hammering on and off, and maintains more consistent comfort with less strain on parts.

Ductless Mini Splits and Zoning: Small Units, Big Efficiency Gains

Ductless mini splits deliver conditioned air right where it is needed, so there are no long duct runs that bleed energy before air reaches the room. With heads placed in priority spaces, comfort becomes room by room rather than whole house all at once. Motorized multi zone ducted systems and ductless setups let different areas run at different temperatures and schedules, cutting wasted conditioning in unoccupied spaces. Think of it like switching on lights only in the rooms being used. Bedrooms can idle during the day, living areas can coast overnight, and utility spaces can stay set back. The result is tighter control, fewer distribution losses, and measurable reductions in runtime.

Installation, Codes and Commissioning: What Really Determines Real World Efficiency

As of the DOE's 2023 M1 update, equipment is labeled under SEER2, EER2, and HSPF2, which better reflect real-world performance. SEER2 uses a tougher external static pressure, 0.5" vs the old 0.1", so ratings are not one-to-one with legacy SEER. Compare only within the same test standard and, in cold climates, look closely at HSPF2 and low temperature capacity. Compliance is enforced after January 1, 2023, and regional minimums vary for central AC.

What happens at install day decides your comfort. A right-sized, well-installed mid-range unit can outperform a poorly installed high rating model. Duct design and the building envelope matter: sealed, properly sized ducts plus insulation and air sealing materially boost delivered efficiency. In our experience at Budget Heating (BudgetHeating.com), airflow and charge errors drive most callbacks.

- Ask for a Manual J load, matched duct design, and a duct leakage test.

- Have static pressure and airflow measured, target 350 to 450 CFM per ton.

- Verify refrigerant charge by subcool and superheat with a signed commissioning sheet.

Modern Heat Pump Variants: VRF, Ground-Source, and Hybrid Options Explained

VRF/VRV heat pump systems circulate refrigerant to many indoor zones and modulate flow so each space gets only the capacity it needs. That capacity matching across zones improves efficiency and comfort. Modulating hydronic heat pumps apply the same idea using water, a natural fit for buildings that use hydronic distribution, including ground-source options.

In cold regions, designs that preserve output at low temperatures matter. Units with enhanced heat exchangers and improved defrost algorithms hold more capacity while limiting frost-related interruptions. Where winter extremes or energy prices warrant it, a hybrid setup pairs the heat pump with a secondary heat source, often a gas furnace, engaging backup only when conditions or economics justify it. Across all categories, manufacturers and specifiers are shifting to low GWP refrigerants and stronger leak management to meet environmental compliance and cut lifecycle impact. Selecting among these approaches typically comes down to zoning complexity, climate, and operating cost priorities.

Controls & Intelligence: The Brains That Make Efficiency Real

Controls turn good equipment into a great system. Think of them as the conductor, keeping every component on the same beat. Smart thermostats and integrated controls use algorithms for setback and staging, and they learn occupancy patterns to cut unnecessary runtime while preserving comfort. Sensor inputs keep the system honest, so it heats or cools where and when it matters.

Building automation ties sensors and software together across zones. With zoning, the platform sequences equipment and ventilation only where needed, then backs off elsewhere. Utility integrated controls participate in demand response, reducing or shifting load during grid peaks to support decarbonization and grid stability. Thermal storage, whether ice, water or phase change, pairs with smart sequencing to pre cool or pre heat during off peak hours, then ride through peaks with less compressor run time. The result is steady comfort that aligns operation with energy and grid realities.

Diagnostics complete the picture. Built in connectivity flags low airflow, coil fouling or other developing faults before they turn into major failures. That is predictive maintenance in practice, turning surprises into scheduled fixes. In our experience at Budget Heating (BudgetHeating.com), customers who enable these alerts catch issues earlier and avoid avoidable comfort complaints.

Air Quality & Heat Recovery Tech Homeowners Often Overlook

Think of an HRV or ERV as the home's lungs that precondition incoming air. Balanced systems exchange stale indoor air with fresh outdoor air while transferring heat, and with ERVs, moisture, so you boost IAQ with a smaller energy penalty. HRV suits cold, dry climates, ERV helps in humid regions or homes fighting winter dryness. Filtration matters too: higher MERV media filters, often 4 to 5 inch, catch fine particles without choking airflow when paired with smart fan control or variable speed blowers. In our experience at Budget Heating (BudgetHeating.com), MERV 11 to 13 is the sweet spot for most homes, while ultra high MERV can require a system designed for the added resistance to keep comfort and efficiency intact.

Common Misconceptions, Debunked (and What to Do Instead)

After decades in the field, we still see the same traps. Pressing the thermostat higher or lower does not speed comfort, it is like mashing an elevator button, the system will not go faster, only run longer. Supply air temperature on many systems is fairly fixed, widening the setpoint gap mostly adds runtime. Bigger equipment is rarely better, oversizing leads to short cycling, poor dehumidification, noise, and early wear, so insist on proper load calculations. Thermostat placement shapes behavior, avoid sun, kitchens, drafts, and nearby supply registers. Skipping filter changes chokes airflow, hurts efficiency, and can freeze coils or overwork blowers. Closing vents to save energy usually raises static pressure, increases leakage, and reduces efficiency. Neglecting maintenance and ductwork invites dirty coils, low refrigerant, and airflow restrictions. Do not shop by SEER alone, correct sizing, duct health, and installation quality often matter more. Practical habits that work: moderate setpoints, smart schedules, right sizing, careful thermostat placement, and on time filter changes.

Not always the best fit: leaky or undersized ducts, replacing equipment without duct repairs is a miss, consider duct sealing or ductless. Small additions or isolated rooms, extending long duct runs can waste energy, a mini split often fits better. Very cold climates, a straight heat pump may struggle, cold climate models or dual fuel systems are smarter choices.

Quick Takeaways, Next Steps, and How to Get a Quote

The outside unit is only part of the story. Comfort, efficiency, and lifecycle cost hinge on the full package: inverter drives, variable airflow, capable controls, balanced ventilation, the refrigerant, and proper installation with commissioning.

Comparing bids can feel tricky. Since 1992 we have fulfilled 200,000+ orders with factory-authorized, U.S.-based support. Do this next: request load calculations, require commissioning and duct leakage tests, verify SEER2 and HSPF2, and ask for an integrated proposal that includes controls, ventilation, and any thermal storage or demand response.

- Get a Custom Quote: load calc review, wholesale pricing, free shipping on many systems, financing with Affirm.

- Talk to Our Team: call our U.S.-based techs for straight answers, not a call center.

- Shop Heat Pumps: in stock with fast shipping from our PA and TX warehouses.