Do you mean LP or Propane? Start Here Before Any Conversion

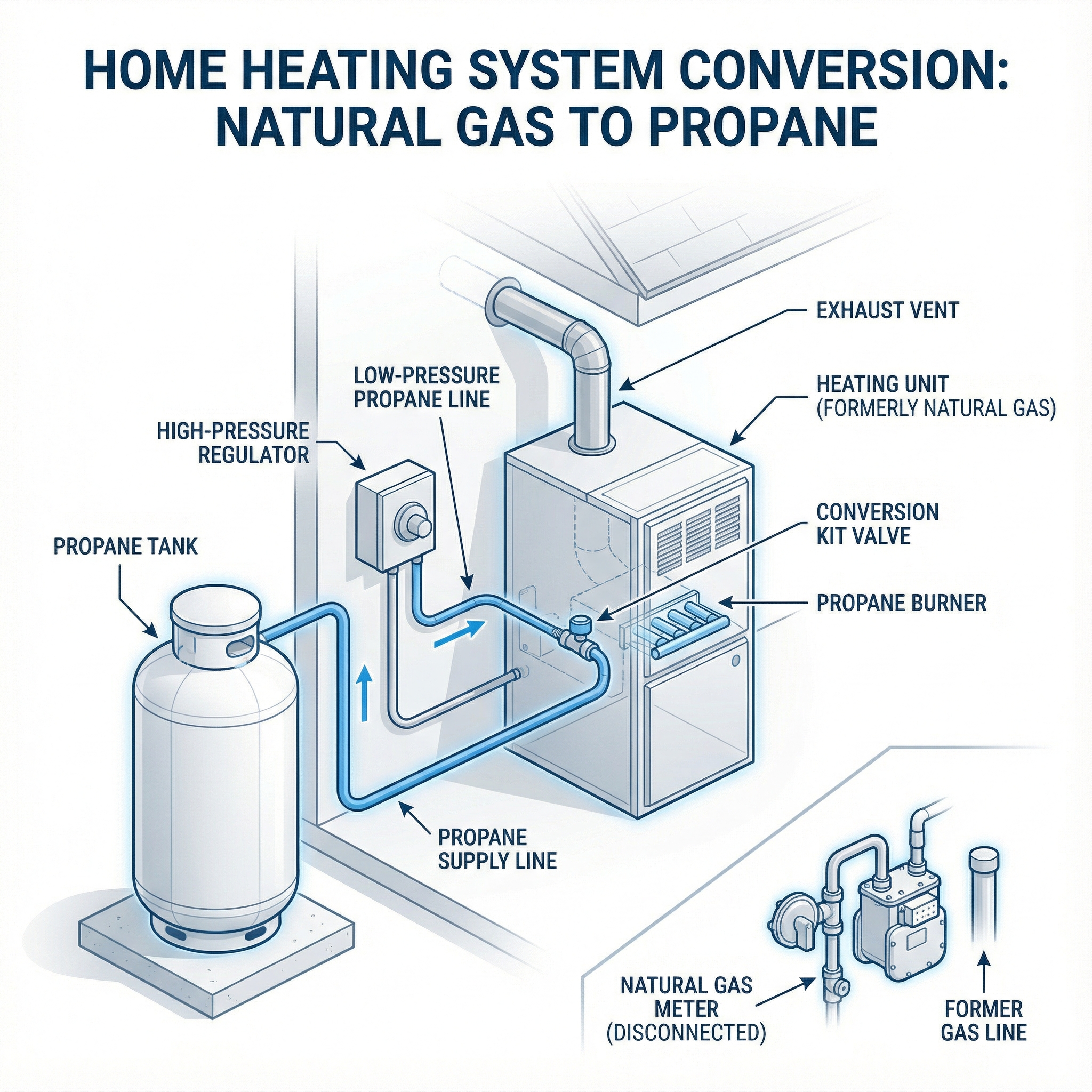

In residential HVAC, LP almost always means propane. In our experience, LP to propane usually means converting a natural gas or oil appliance to propane. That conversion affects burners, orifices, regulators, venting, and safety controls, so it must follow the manufacturer's instructions and fuel gas codes, and be performed and documented by a licensed HVAC or gas pro. Start by confirming the appliance is convertible, sizing and planning the propane tank and piping, and matching the design to efficiency rules and local permits.

What this guide covers: an overview of converting a heating system to propane

We map the full path to converting a heating system to propane. LP and propane are used interchangeably as noted above. This guide is written for homeowners, mechanically inclined DIYers, property managers, and HVAC technicians. We focus on planning, required parts, permits and code checks, appliance conversion kits, regulator and orifice selection, job sequencing, leak and pressure testing, combustion setup, and final documentation for inspectors and warranties. Think of it like a flight checklist, every step has a purpose and a pass or fail. The aim is a safe, code compliant conversion, not casual tinkering, with clear points to defer to a licensed pro.

Safety, codes and permits: what rules govern a propane conversion

Propane conversions follow NFPA 54 or the IFGC for piping and appliances, and NFPA 58 for storage and delivery. Local authorities require permits and inspections for conversions, tank placement, and mechanical work. Contact them early to confirm scope, timing, and insurance notices, and use licensed contractors where required.

Regional factors drive design. Cold climates need venting and condensate protection that will not ice. High altitude affects appliance sizing. Coastal or corrosive sites need setbacks and anchoring that meet local rules. In our experience at Budget Heating (BudgetHeating.com), AHJs enforce siting clearances.

Policy shapes choices. DOE minimums are rising, including the 95 percent AFUE furnace standard on Dec 18, 2028. SEER2 and the refrigerant transition under the HFC phasedown also apply. Some areas add low-NOx or electrification rules. Choose equipment with these dates in mind so it passes now and stays compliant later.

Homeowner checklist: plan, permits, contractor questions and day of steps

Use this checklist to plan, vet your installer, and know what to expect on conversion day. In our experience at Budget Heating (BudgetHeating.com), confirming OEM LP kit part numbers early prevents delays.

- Plan: verify each appliance is convertible to LP and record the OEM LP kit part number. List appliances and total BTU/hr to size tanks, regulators, and piping.

- Tank and site: with your propane supplier, select storage size, meet setbacks, plan fill access, and ensure combustion and ventilation air.

- Ask contractors: do you use OEM LP kits? how will you set manifold pressure and verify with a calibrated manometer? will you replace orifices, tune combustion, and leave labels and combustion printouts?

- Day-of: safe the system, verify tank and regulators, swap orifices and gas-valve parts per OEM kit, set manifold pressure, adjust airflow or primary air, leak-test, verify venting and condensate.

- After: track comfort and energy bills for a month, book a 1 to 2 week follow-up, keep manuals, permits, and printouts, and ask about rebates or incentives.

Why homeowners choose propane: benefits compared with oil, natural gas and electric

From what we see in the field, propane delivers steady, cold climate comfort with high efficiency furnaces, yet avoids the soot, odor, and tank sludge of oil. It performs like natural gas without needing a utility line, a strong fit for rural homes that want on site reliability. It also pairs cleanly with modern heat pumps in dual fuel setups, using the pump in mild weather and propane when temperatures plunge. Think of it as one fuel key for the whole house, covering space heat, water heat, cooking, and standby power. High AFUE models are widely available and may qualify for incentives, improving lifetime value.

Honest tradeoffs and common mistakes: when propane isn't the best choice

We work with propane every day, but it is not always the right path. It can be a poor fit in dense cities facing electrification or where natural gas is available, in jurisdictions with very low NOx rules that limit equipment choices, or when the home needs costly duct or envelope fixes first. In those cases, high efficiency electric heat pumps shine in milder climates or where incentives exist, and geothermal can deliver whole home efficiency if the budget allows.

Common misconceptions we see: LP and propane are interchangeable terms, any appliance can be converted, and a DIY orifice swap is all it takes. The reality: convert only listed equipment, and plan for tanks, regulators, piping, permits, inspections, venting, and condensate handling. Propane itself is not inherently unsafe when installed and maintained by licensed pros, and it burns cleaner than oil. Replacing old oil with a condensing propane furnace only makes sense when infrastructure and local codes support it.

Parts, tools and who should do the work: professional vs homeowner tasks

From decades on jobsites, our rule is simple: anything that touches gas, flame, or refrigerant belongs to a licensed pro. Homeowners can handle light upkeep.

- Homeowner tasks: replace or clean filters, keep outdoor clearances and vent terminations free of debris or snow, do visual checks for soot, corrosion, or unusual odors, and test and maintain CO and propane detectors.

- Licensed professional work: install OEM LP conversion kits, change burner orifices or jets, set and verify manifold pressure with a manometer, install and regulate tanks and piping, add shutoffs, sediment traps, and approved flex connectors, perform combustion analysis, handle any refrigerant work by an EPA certified tech, and commission the system.

Required parts and tools: OEM LP kits with model specific orifices or jets, gas valve springs, labels, approved regulators, shutoffs, sediment traps, gas rated sealant, flex connectors, a calibrated manometer, and a combustion analyzer.

Emergency procedure: if you smell gas, evacuate, avoid switches or flames, call the propane supplier or fire department from a safe distance, and do not re enter until cleared.

Efficiency and system selection: AFUE, SEER/SEER2 and climate considerations

AFUE tells you how much of each dollar in fuel becomes usable heat. A 95% AFUE propane furnace turns 95 cents into heat and loses 5 cents in flue losses. Modern propane furnaces commonly reach 90 to 95% or higher. The federal 95% AFUE standard taking effect in 2028 effectively points most new installs toward condensing designs.

For cooling, SEER and the updated SEER2 rate seasonal efficiency. Think of them like miles per gallon for your AC. SEER2 uses a tougher test method, so a SEER2 value is not directly comparable to an older SEER tag. Regional minimums commonly land around 14 to 15.

Selection should follow climate. In our field work, cold regions benefit from sealed combustion, condensing propane furnaces. Plan condensate routing and freeze protection. In milder zones, a dual fuel setup, heat pump paired with a propane furnace, can optimize seasonal efficiency. When replacing cooling during a propane conversion, meet at least your regional SEER or SEER2 minimums.

Costs, quotes and documentation: what to budget and how to get reliable estimates

There is no reliable one-size price. Site specifics drive totals: tank rental or purchase, trenching, piping length, permits, OEM conversion kit needs, labor, and any venting or condensate work. Ask for an itemized proposal that lists: conversion kit part numbers, labor hours and rates, permit fees, tank set, regulators and piping, startup and combustion testing with printouts, and one follow-up visit.

Before signing, ask about rebates or tax credits, confirm warranty impacts, and keep manuals, permits, inspection signoffs, and combustion printouts for records and resale.

Next steps: safety checklist and how to move forward with a licensed pro

Treat a propane conversion as a system upgrade. Verify convertibility, size and site tanks and piping per NFPA and IFGC, use OEM kits, and hire a licensed pro who follows manufacturer instructions and can document combustion and leak tests at commissioning. Close out with a short safety checklist. Done right, you get reliable cold-climate comfort, cleaner than oil, high-efficiency and dual-fuel ready performance that stays durable and code compliant. Our U.S.-based team can spec equipment and coordinate closeout with your installer.

- Get a Custom Quote

- Talk to Our Team by phone

- Shop Gas Furnaces, Heat Pumps, and Dual-Fuel Systems