What Is a 3 Zone Mini Split? Definition, Components, and Typical Capacity

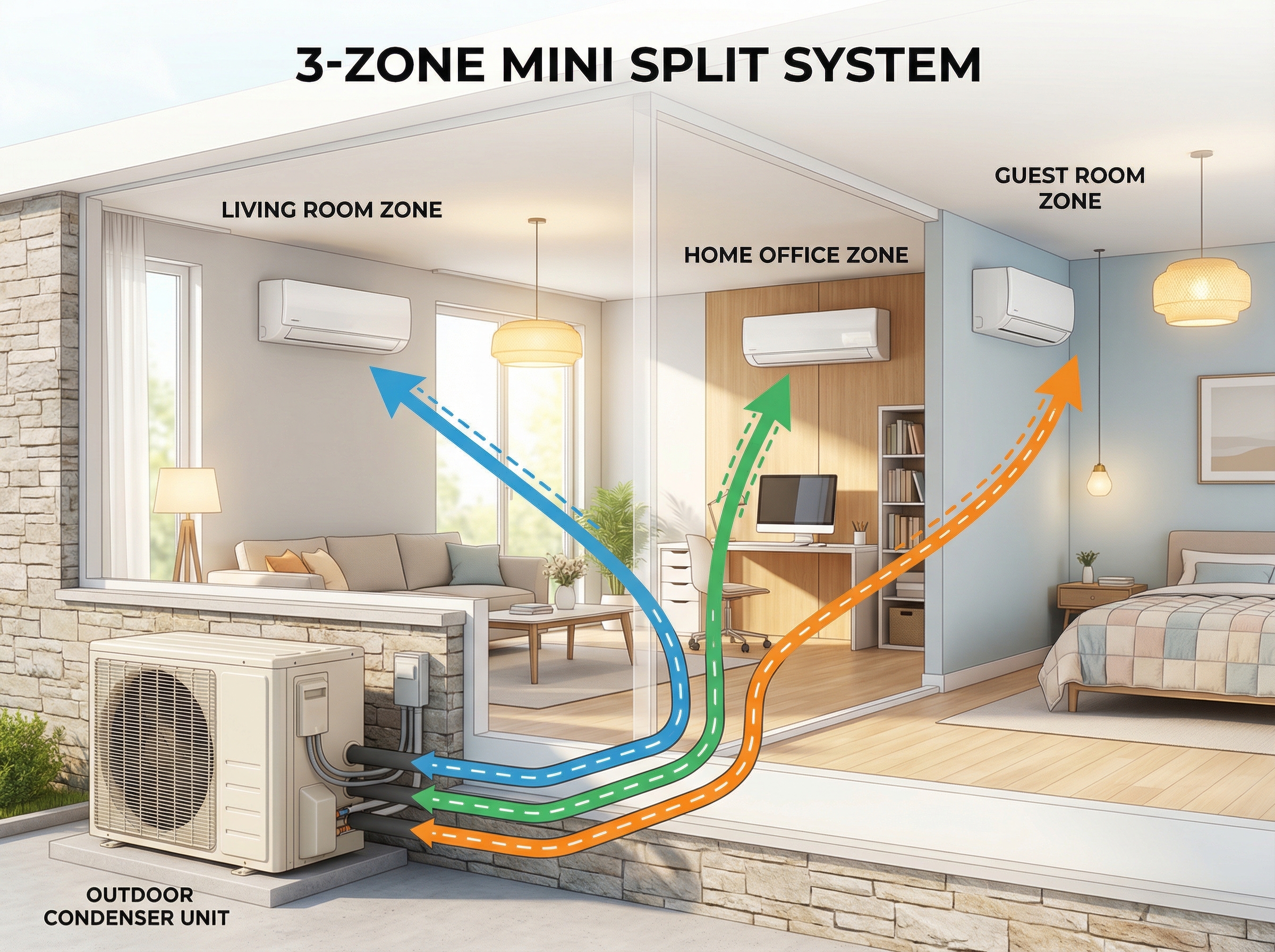

A 3-zone mini split is a ductless setup with one outdoor condenser connected to three indoor air handlers, each serving an independent room or zone. Think of it like one engine powering three independent lanes, so you can set different temperatures where you need them. Indoor units come as wall mounts, ceiling cassettes, floor consoles, or small ducted handlers to match layout and aesthetics. Typical combined capacity runs 18,000 to 36,000 BTU, which, when properly sized, covers about 1,200 to 2,500 sq ft.

How a 3 Zone Mini Split Works: Indoor Heads, Outdoor Unit, Line Sets and Zoning

A multi zone outdoor unit uses an inverter driven compressor to serve several indoor heads at once. Each head mounts in its room and connects back to the outdoor unit through copper refrigerant line sets and a condensate drain. The line sets carry refrigerant between the outdoor coil and the indoor coils, while the drain carries away moisture that the indoor coil removes during cooling.

The system relies on the refrigeration cycle to move heat. In cooling mode, the indoor coil absorbs heat from the room air and the outdoor coil rejects it outside. In heating mode, a reversing valve changes refrigerant direction so the outdoor coil gathers heat and the indoor coil releases it to the room. Because the compressor is inverter controlled, it can modulate capacity up and down to match the combined demand from all connected heads rather than just running at one speed.

Zoning is built in. Each indoor head has its own controls and schedules, so one room can be cooler while another runs warmer, all without ductwork. The outdoor unit is selected to cover the combined loads and must stay within the manufacturer port limits. Installation requires proper routing and connection of the refrigerant line sets and secure condensate drains, which is why copper and refrigerant handling are central to the job.

3 Zone Mini Splits vs. Single Zone and Central AC: Benefits, Limits and Realistic Expectations

Three zone mini splits shine when you want targeted comfort. They avoid duct losses and let you set each room independently, often with less invasive installation than adding full ductwork. Used for zoning with high efficiency equipment, they commonly cut cooling energy 30 to 40 percent versus conventional central AC. Many models heat and cool year round, run quietly indoors, and outperform window units or leaky ducts on efficiency.

- Myth: You need three outdoor units.

- Myth: Mini splits require ductwork.

- Myth: Installation has a fixed price.

- Myth: Mini splits are only commercial.

Where they are not ideal: if you need identical whole house conditioning and already have tight, efficient ducts, central AC can be the better fit. In very cold climates, performance can drop below about 25 F unless you choose a cold climate heat pump or add backup heat. For extreme cold, a gas furnace or dedicated cold climate heat pump is usually the safer path.

Typical Equipment Costs: Outdoor Units, Indoor Heads and Common Accessories

For a three-zone mini split, the equipment total is driven by the outdoor multi-port condenser, three indoor heads, and the accessory kit that ties it all together. Pricing scales with total capacity and efficiency ratings (SEER, SEER2, HSPF2). Choosing higher efficiency is like moving up a trim level in a car, better performance and features, higher unit cost. In our experience at Budget Heating (BudgetHeating.com), the head styles you pick and climate add-ons are what swing quotes most.

- Outdoor multi-zone condenser: Larger capacity and higher SEER2 models cost more. Cold-climate readiness often involves add-ons that raise the price.

- Three indoor air handlers: Wall-mounted heads are the most economical. Ceiling cassettes, floor consoles, or slim ducted handlers carry a premium for the hardware.

- Accessories and install materials: Line sets and control wire for each head, condensate pumps where gravity drain is not possible, base-pan heaters for freezing climates, wall or pad mounts for the condenser, and line-hide covers. Each item is modest on its own, but together they form a meaningful slice of the equipment total.

Factors That Affect Installation Cost: Home Layout, Line Set Runs, Efficiency and Local Rules

In our experience, price hinges on total BTU and efficiency (SEER/SEER2, HSPF2), count and type of indoor units, line set length and routing, needed electrical upgrades, local labor and permit fees, plus any drywall or finish work. Updated DOE tests, SEER2 and HSPF2, set regional minimums and influence incentive eligibility. Many 3 zone jobs sit under 45,000 BTU, which triggers specific SEER2 minimums.

- Collect room sizes, window orientation, insulation, design temps.

- Request a room by room Manual J load.

- Choose indoor head styles.

- Plan line set routes and condensate drains.

- Require model numbers, SEER/HSPF, and AHRI certificates on quotes.

Average Cost to Install a 3 Zone Mini Split: National Price Ranges and Per Zone Rules of Thumb

For a standard three zone mini split, mainstream installed projects commonly cluster around $6,500 to $11,000 for typical residential retrofits. When the home layout and line set runs are moderate in complexity, a practical typical range is roughly $6,500 to $9,500. Think of the outdoor unit as the base and each indoor head as an add on, like adding rooms to a renovation, the total rises with each zone.

As a rule of thumb, each additional indoor head or zone adds about $1,000 to $3,000 for the unit, lines, and labor. That is why three zone systems often land in the mid thousands to low five figure range. In our experience at Budget Heating (BudgetHeating.com), this per zone adder is the quickest way to sanity check a quote before you dive into brand or feature choices.

Premium brands, very high SEER equipment, or complicated long run installations can push totals into the mid teens, approaching or exceeding $15,000 to $18,000. Use these ranges as ballparks to see where your project is likely to fall before you start collecting bids.

Labor Cost to Install a Mini Split: What Professionals Do and Typical Labor Scope

On a mini split quote, labor is its own line because it covers mounting indoor heads, routing and insulating line sets, cutting and patching walls, electrical work if included, plus system testing and final commissioning. The price shifts with home layout, number of zones, and your region.

Refrigerant tasks must be handled by a licensed HVAC technician: brazing, pressure testing, evacuation, and charging. Any panel work or dedicated circuits should be done by a licensed electrician. These specialists add cost, but they are required for safety, code compliance, and to preserve manufacturer warranty. Many manufacturers require professional installation and permitted electrical work. DIY on these items can jeopardize coverage.

Detailed Installation Cost Breakdown: Materials, Permits, Electrical Work and Commissioning

Non-equipment items add up: permits and inspections $100 to $300. Electrical work, a new dedicated circuit or minor panel work, runs $200 to $500, more if the panel must be upgraded. Materials include line set, fittings, pad, disconnect, whip, and condensate parts, tubing or a pump. Commissioning includes nitrogen pressure test, deep vacuum to spec microns, weighing in charge, verifying condensate, electrical checks, and testing each zone in heat and cool, with documentation. This is why it is billed.

Real World Examples, Operating Costs and How to Save on a 3 Zone Mini Split

In our installs, a 3 zone often serves a living area, a home office, and a guest room. Condition only spaces you use to cut runtime. Maintenance is simple: clean filters monthly in season, check coils and line sets in spring and fall, and get a yearly pro tune up, usually $75 to $200, roughly $6 to $17 per month.

- Use incentives: federal 25C credit on qualifying heat pumps, often capped near $2,000, plus state or utility rebates. Ask your contractor for the AHRI certificate and paperwork.

- Spend smart: target needed zones, choose mainstream SEER if budget is tight, request itemized quotes, schedule installs in shoulder seasons, and have rebate eligibility documented.

Is a 3 Zone Mini Split Right for Your Home? Final Checklist and Next Steps

A 3 zone mini split is a flexible, high efficiency solution for homes needing independent control across multiple rooms. Comparing bids can be tricky, so use this quick checklist before you sign:

- Verify model numbers, SEER/HSPF, and AHRI certificate.

- Get a room by room load and a clear scope: equipment, line sets, electrical, permits, finish repairs.

- Confirm commissioning steps and warranty terms.

- Request itemized pricing to compare apples to apples.

Need a second set of eyes? Our 30+ years of HVAC experience and U.S.-based phone support are here to help.

- Get a Custom Quote

- Talk to Our Team by phone

- Shop 3 Zone Mini Splits

- Affirm financing and free shipping on many systems

learning center

learning center

money saving tips

money saving tips

Cooling

Cooling Heating

Heating Product and Brands Insights

Product and Brands Insights Buying Guides

Buying Guides State by State

State by State HVAC Systems

HVAC Systems