What Are the Components of a Residential HVAC System?

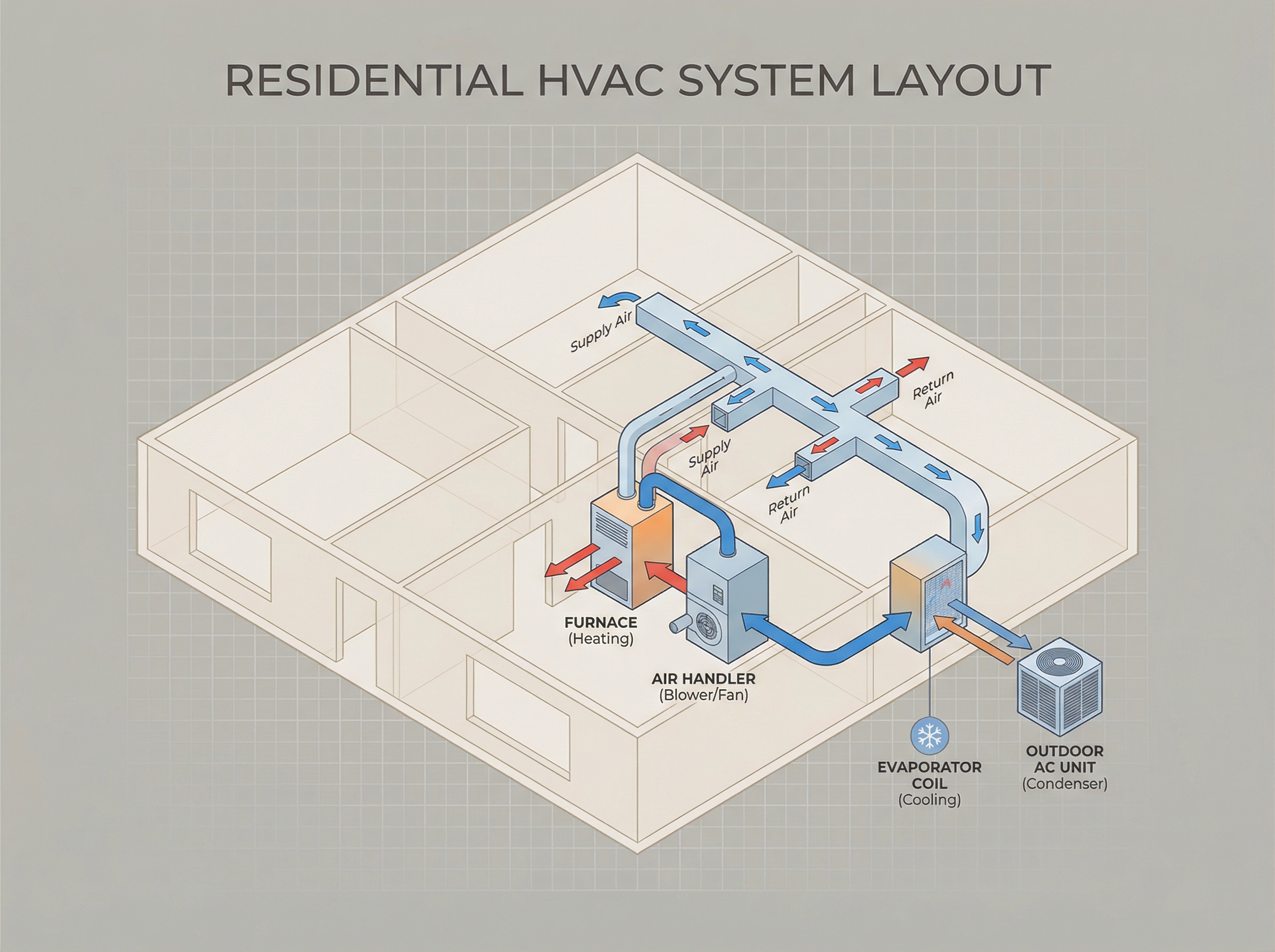

A residential HVAC system is a set of parts that heat, cool, and move air throughout the home. We think of it like a relay team, each component handing off comfort to the next. Knowing the players helps you keep rooms even, energy costs in check, indoor air cleaner, and equipment lasting longer with simple upkeep.

- Thermostat: the control that calls for heating or cooling.

- Furnace or air handler: heats air with burners or moves air with a blower, sometimes both.

- Outdoor condenser or heat pump with compressor: releases or gathers heat outside depending on mode.

- Evaporator coil: indoor coil that cools and dehumidifies air during AC or absorbs heat in heat pump mode.

- Refrigerant line set: copper lines that carry refrigerant between the indoor coil and outdoor unit.

- Ductwork, supply and return: the pathways that deliver conditioned air and bring air back.

- Supply and return vents: room grilles and registers that distribute air and pull it back.

- Primary air filter(s): captures dust to protect equipment and improve air quality.

- Condensate drain and pan: removes moisture produced during cooling to a safe drain point.

Understanding how these parts interact supports comfort, trims utility bills, protects indoor air quality, and extends system life with routine maintenance.

How a Residential HVAC System Works: Quick, System-Level Overview

In our experience, a home HVAC works like a relay race: the thermostat sends a call to heat or cool, control boards energize the right components, the blower moves air across a heat exchanger or evaporator coil, then pushes conditioned air through ducts to the rooms. In cooling, the refrigerant cycle and the outdoor condenser with compressor carry heat outside; with heat pumps, that flow can reverse to bring heat indoors. Electrical controls and safety devices coordinate timing, staging, and defrost, and shut things down if limits are crossed. Real performance hinges on proper airflow, accurate refrigerant charge, solid duct design, and clean safety wiring.

Major Outdoor Components: Condenser Unit, Compressor and What Owners Should Maintain

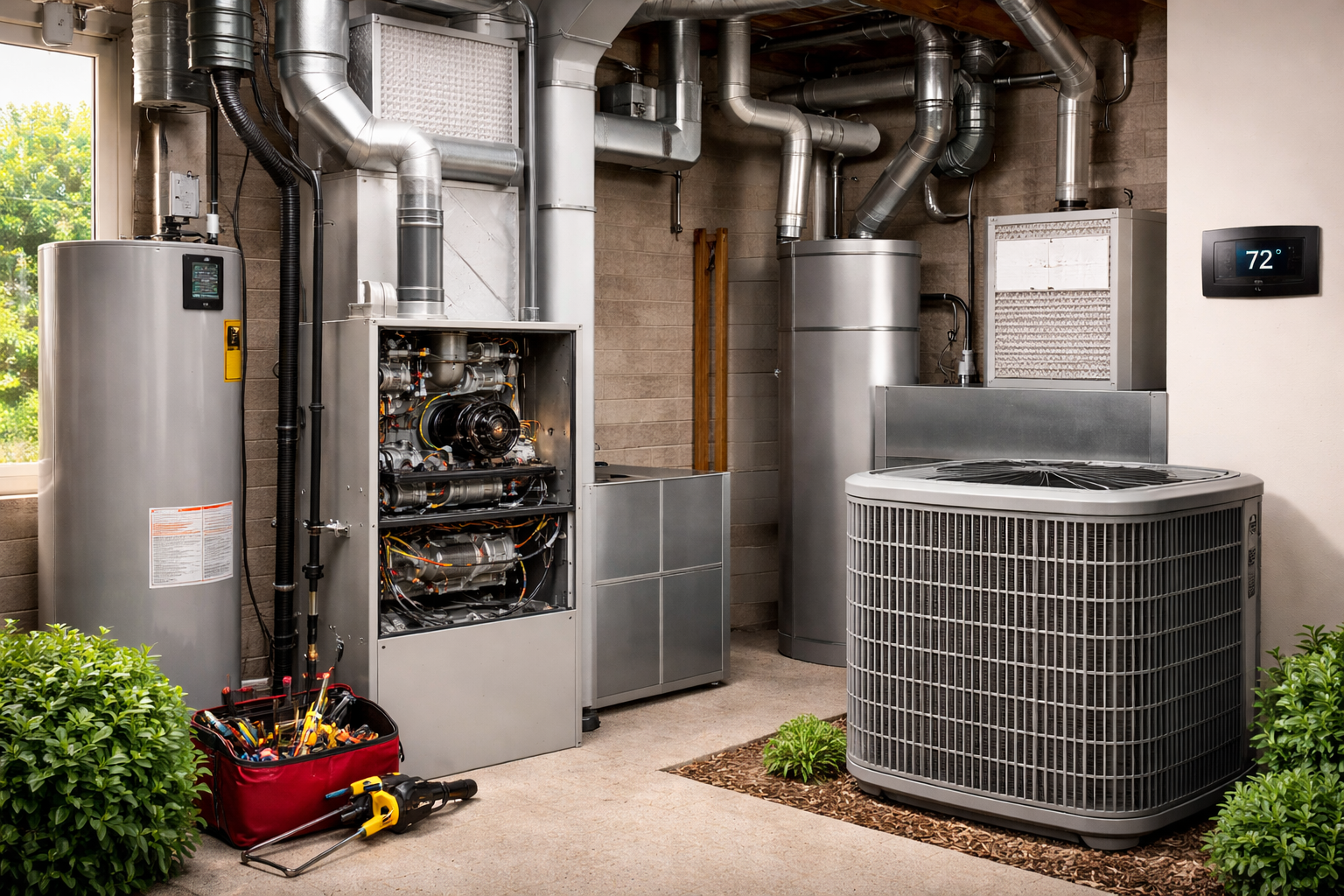

The outdoor condensing unit houses the compressor, condenser coil and a fan. During cooling it rejects heat outdoors, and the compressor is the workhorse that pressurizes the refrigerant so the coil can shed that heat to the outside air. Think of the compressor as the heart that keeps refrigerant moving, and the coil as the place where heat is released.

Simple seasonal care goes a long way. In our experience at Budget Heating (BudgetHeating.com), a clean, unobstructed condenser is the easiest win for performance and longevity.

- Maintain about 2 to 3 feet of clearance on all sides.

- Remove leaves, grass clippings and debris from the cabinet and base.

- Gently rinse the condenser coil.

- Straighten minor bent fins.

- Verify the unit is level.

- Keep vegetation trimmed back to protect airflow.

Indoor Components: Furnace, Air Handler, Evaporator Coil and Condensate Management

The furnace generates heat with burners that warm a sealed heat exchanger. Household air passes over this metal surface, picks up heat, and the combustion gases are vented outdoors, never mixing with indoor air. An air handler houses the blower and, in many systems, electric heat strips. Both units move air through ducts for heating or cooling.

During cooling, the evaporator coil absorbs heat from indoor air. A metering device, either a TXV, EEV, or fixed orifice, regulates refrigerant into the coil. Copper line sets connect indoor and outdoor units, and correct sizing with intact insulation on the suction line preserves capacity and prevents sweating.

Moisture that forms on the coil drains into a pan, then out through a trapped drain line. Where gravity will not work, a condensate pump lifts water to an appropriate discharge point. In our decades of field work, most water issues trace back to blocked drains or failed pumps.

- Seasonally inspect the indoor coil for dirt or ice.

- Clear the condensate drain with vinegar and confirm the pan is dry.

- Check suction line insulation and secure refrigerant lines.

- Keep about 30 inches of clearance and ensure access panels are latched.

Blower Motor, Fans and Airflow Management: Why CFM and Static Pressure Matter

The blower is the system's lungs, moving air across the coils and through ducts. ECM or variable-speed motors run longer at lower speeds, which tightens humidity control, boosts filtration, lowers noise, and typically uses less electricity than single-speed. In field diagnostics we often see high static pressure choke airflow, reducing comfort and efficiency. Correcting incorrect blower setup and clearing restricted filters or coils can deliver roughly a 24% gain in AC or heat pump efficiency.

Quick checks: feel for strong, even supply airflow and clear returns. In cooling, a supply to return temperature drop of about 16 to 22 F usually indicates normal operation.

Ductwork, Vents and Registers: Delivering Conditioned Air Efficiently

Supply ducts deliver conditioned air to rooms and returns pull it back. When ducts are correctly sized, with few sharp bends, sealed joints and proper insulation, you get quieter operation, even temperatures and less wasted energy. Think of ducts like roadways for air: if the routes are narrow, kinked or leaky, traffic slows and your system works harder.

Practical Manual D design means sizing each trunk and branch to the room load, limiting long flex runs and tight elbows, and keeping total static pressure in the sweet spot. Done right, sealing and insulating ducts can increase cooling capacity by about 33 percent and improve seasonal efficiency by roughly 16 to 41 percent. When duct sealing is paired with correcting airflow and refrigerant charge, homes often see around 12 to 47 percent HVAC energy savings and lower peak electrical demand. In our experience at Budget Heating (BudgetHeating.com), poor duct layout and low return air are the top causes of comfort complaints on otherwise good equipment.

- Common signs: rooms that are always too hot or too cold, noisy vents, dust streaks at grilles, long run times and higher bills.

- Quick checks you can do: look for disconnections, kinks, crushed flex and unsealed joints. Seal small leaks with mastic or UL-181 foil tape, then insulate ducts in attics or crawlspaces.

- Keep supply registers and return grilles clear of rugs and furniture so air can move freely.

- If rooms stay off, request a duct leakage test and air balancing. Verify you have adequate return paths and that all ductwork in unconditioned spaces is sealed.

Thermostats & Control Systems: Managing Comfort, Schedules and Zones

In our experience, the thermostat is the system brain, setting temperature targets and modes. Common types include non-programmable, programmable models that follow daily or weekly schedules, and smart Wi‑Fi controls with geofencing and energy reports. Placement matters, keep it out of drafts, direct sun, and away from supply vents for accurate readings. Optional zoning uses motorized dampers, multiple thermostats, and a zone control board to manage different areas independently. For schedules, use modest setbacks and stay consistent rather than large swings that drive long runtimes.

- Change thermostat batteries annually if needed.

- Verify the correct system type setting, heat pump vs conventional.

- Review schedules seasonally and avoid extreme setpoints.

Air Filtration, Purifiers and Indoor Air Quality Components

Filters protect internal components and clean the air that circulates through the home. Higher MERV ratings capture finer particles, but like a tighter coffee filter they add resistance if the system lacks airflow capacity or filter area. When stepping up in MERV, use a larger media cabinet to keep pressure drop in check. Some jurisdictions and codes, including parts of California under Title 24, require MERV 13 in new homes, which affects fan sizing.

Indoor air quality add ons support specific goals: whole home humidifiers or dehumidifiers manage humidity, UV or electronic air cleaners target microbes and fine particles, and ERV or HRV units exchange stale and fresh air with energy recovery.

- Check filters monthly and replace every 1 to 3 months; install with the arrow pointing toward the blower.

- For MERV 13 goals, increase filter face area or use a low resistance media cabinet to control static.

Limitations, Safety and When to Call a Pro (Honest Tradeoffs and Maintenance Boundaries)

Honest tradeoffs matter. We match equipment to climate, loads and code realities, not just ratings. Some setups are not ideal, and there are safer boundaries for DIY work.

- Very cold winters: standard heat pumps lose output and efficiency. Better choices are a cold climate heat pump, a dual fuel setup, or a high efficiency gas furnace.

- Leaky or undersized ducts: the highest SEER will not deliver if the duct system is compromised. Fix ducts first, or consider ductless mini splits for targeted spaces.

- Refrigerant shifts: with DOE SEER2 testing and the AIM Act phasing down HFCs, legacy R‑410A can be harder to service over time. A2L ready systems using R‑32 or R‑454B align with new rules and practices.

Safe homeowner tasks:

- Replace filters, update thermostat batteries and schedules.

- Shut power off, then clear debris around the outdoor unit.

- Flush the condensate line.

Pro only:

- Electrical diagnostics or repairs, refrigerant recovery or charging, combustion work, compressor or complex airflow problems.

Critical safety:

- De energize equipment before any inspection.

- Never handle refrigerant without certification.

- Install and maintain CO and smoke detectors. If you smell gas or suspect CO or a cracked heat exchanger, evacuate and call a professional.

Common traps: bigger systems short cycle, highest SEER cannot fix bad installation, closing too many vents harms equipment, extreme setpoints do not speed comfort, filter intervals vary by home and MERV.

Summary: Key HVAC Components, Maintenance Priorities and Next Steps

Your HVAC is a connected system, from thermostat and controls to heat source, indoor coil or air handler, outdoor condenser and compressor, refrigerant lines and expansion device, blower and ductwork, filters and IAQ add ons, condensate drainage, and safety or electrical devices. When components are matched and correctly sized, with solid ductwork and professional installation, you get the best comfort, efficiency, and equipment life.

Prioritize regular filter changes, clear vents, basic outdoor unit and drain care, and schedule professional tune ups twice per year. Call a licensed pro for electrical, refrigerant, or combustion work. If replacing, insist on Manual J sizing, properly matched sets, duct evaluation, and SEER2 or HSPF2 ratings.

If you are weighing next steps, our team has 30 plus years of hands on HVAC experience and U.S. based phone support to guide you from selection to start up.

- Get a Custom Quote

- Talk to Our Team by phone or live chat

- Shop Heat Pumps, Furnaces and Air Handlers

- Factory authorized dealer with full manufacturer warranties, financing with Affirm available

hvac systems

hvac systems

learning center

learning center

money saving tips

money saving tips

Cooling

Cooling Heating

Heating Product and Brands Insights

Product and Brands Insights Buying Guides

Buying Guides State by State

State by State