Why the HVAC Refrigerant Landscape Is Changing: A Practical Overview

With more than 30 years in HVAC, we are watching a pivotal shift unfold, the move away from high GWP R 410A toward next generation A2L refrigerants, especially R454B and R32. It is driven by 2026 focused regulations and global climate policy that phase down high GWP HFCs and steer manufacturers to lower impact options. The refrigerant in your system influences comfort, energy bills, indoor air quality, and the long term reliability of the equipment, not just environmental footprint.

R454B and R32 behave differently than legacy blends. They are A2L class, mildly flammable, and their composition and pressures call for updated safety practices, revised codes, and training for installers. Think of it as switching to a cleaner fuel that needs proper handling and equipment to perform safely and efficiently. In this guide, we outline what is changing, how R454B and R32 compare in safety, pressures, efficiency, and environmental impact, and what that means for new systems and any talk of retrofits. We also cover practical steps, staying current on codes, proper storage and handling, and choosing equipment rated for A2L refrigerants so you stay comfortable and compliant.

Regulatory Drivers: Kigali, the AIM Act and the 2026 Shift

The U.S. HFC phasedown under the AIM Act is reducing supplies of high-GWP refrigerants like R-410A. Effective January 1, 2026, manufacturers must stop producing new U.S. central AC and heat pumps charged with R-410A. New comfort-cooling equipment will use lower-GWP A2L refrigerants, mainly R454B for ducted lines and R32 for many ductless and some ducted platforms. Existing R-410A systems can stay in service and be repaired, but replacement refrigerant will grow costlier and less available as quotas tighten. The shift aligns with updated federal efficiency targets and evolving safety codes, including UL 60335-2-40 for A2L certification, labeling and installation. We are seeing A2L-ready lines in 2026, with broader availability through 2026 as codes, training and supply chains align.

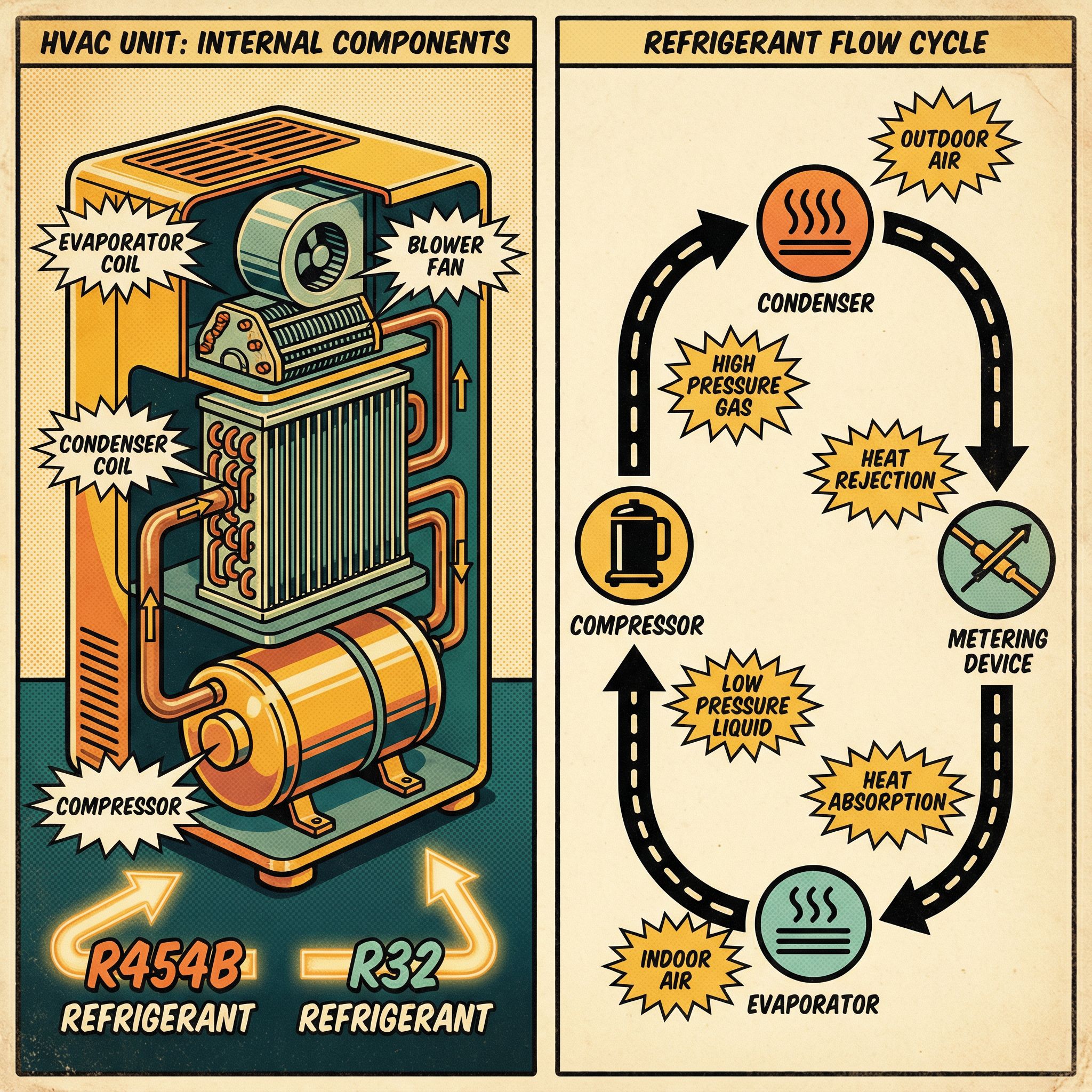

Meet R454B and R32: What They Are and How They Differ

R454B and R32 are next generation HVAC refrigerants that reduce climate impact versus R 410A without sacrificing comfort. Global warming potential, or GWP, compares a gas to carbon dioxide in how much heat it traps, like a score where lower is better. R454B usually has a lower GWP than R32, and both are far below R 410A, aligning with HFC phase downs under U.S. SNAP and the Kigali Amendment.

- R454B runs at pressures similar to R 410A, so many R 410A platforms adapt with fewer component changes, helping contain transition complexity and cost, and similar efficiency when engineered correctly.

- R32 can reach higher SEER2 due to strong heat transfer and volumetric capacity, and its single component makeup can simplify some service steps.

- Both are A2L, mildly flammable, so use ventilation, temperature limits, distance from ignition sources, and updated labeling per code.

In our experience, the practical path is matched A2L rated equipment installed by A2L trained contractors after confirming compatibility.

Cost & Savings: Equipment, Service and Lifetime Economics

Think of total cost of ownership like a car: sticker price matters, but fuel, maintenance, and reliability decide what you really spend. For HVAC, that means equipment, installation labor, refrigerant, energy, upkeep, and expected lifespan.

On equipment, R454B runs at pressures similar to R-410A, so many manufacturers can adapt existing platforms, limiting production cost increases and easing some retrofits. Operating cost hinges on efficiency. Moving from mid-teens to high-teens or low-20s SEER2 typically trims cooling kWh by about 20% or more when sized and installed correctly. R32 models often post 5 to 10% higher SEER/SEER2 than comparable R454B units. If you spend $500 to $800 a year on cooling, that edge is roughly $25 to $80 annually.

Service economics: HFC phase down points to higher per-pound refrigerant prices, yet labor usually dominates invoices. Preventive maintenance, leak checks, and solid commissioning keep lifetime costs in check. In our experience at Budget Heating (BudgetHeating.com), the best quotes break out equipment, labor, and refrigerant, then factor energy savings and available rebates so the customer sees lifetime value, not just a low price.

Installation Checklist: Sizing, Charge, Linesets and Commissioning

- Identify the existing system: read the nameplate for refrigerant, note age, repairs and any leak history. For 10-12+ year systems or repeated failures, compare repair with A2L compatible replacement.

- Screen installer readiness: confirm training on A2L procedures, UL 60335 2 40 and local codes. Choose your path, R32 or R454B, based on support and service characteristics.

- Right size with Manual J: require a room by room load calculation. Match tonnage to the load to avoid short cycling and poor humidity control. Inspect, seal and resize ducts as needed.

- Select matched equipment: verify SEER2/EER2/HSPF2, metering device, and whether the lineset can be reused or must be replaced.

- Electrical readiness: confirm breaker size, wire gauge and MCA/MOP.

- Brazing and pressure test: purge with nitrogen during brazing, then pressure test with dry nitrogen.

- Evacuation and charging: evacuate to 500 microns or lower with a standing decay test. Charge strictly by measured weight.

- A2L site practices: maintain ventilation, keep ignition sources away, respect room volume and charge limits, and do not store cylinders at home.

- Commissioning wrap up: EPA compliant recovery and disposal, warranty registration. For heat pumps, review cold climate performance, defrost and backup heat. Plan annual maintenance and a qualified leak response.

Technical Comparison: Pressure, Capacity and Real World Efficiency

SEER and the updated SEER2 rate seasonal cooling per kWh, so higher values mean lower energy use. Since the 2023 DOE update, compliance is based on SEER2, EER2 and HSPF2 with higher floors: about 13.4 in the North, 14.3 in the Southeast and Southwest, and 14.3 nationwide for heat pumps. In practice, code minimum systems cluster in the mid teens.

All else equal, R32 systems often deliver roughly 5-10% higher SEER2 than comparable R454B, and R454B is a small step up from legacy R 410A. In hot ambients, R32 tends to hold efficiency better, widening real world savings on peak days. Refrigerant alone does not set SEER2, full design does, from coils and compressors to controls and airflow. In our experience at Budget Heating (BudgetHeating.com), matching these metrics to climate and code helps avoid surprises in load, pressure and operating cost.

When R454B or R32 Might Not Be the Best Fit: Tradeoffs & Alternatives

We like R454B and R32 for their lower GWP, but they are not drop in refrigerants. They are A2L, so only equipment specifically listed for A2L with proper controls and labeling should be used. Retrofitting an R 410A system without OEM approval and code compliance is a risky path.

- Mid life systems in good shape: If an R 410A unit still has years left, forcing an A2L retrofit is rarely wise. Consider a phased plan instead, and invest in duct sealing, airflow fixes, and better controls while you wait.

- Sites with limited A2L readiness: Where codes, ventilation, or local service support are not in place, choosing an equipment family that is well supported locally, or staying with R 410A while permitted, can be more practical.

- Questionable line sets or oversizing: You cannot assume an existing line set is reusable. Verify compatibility and cleanliness. If the current system is oversized, perform a Manual J and correct ducts before any refrigerant change.

Retrofit vs new equipment: In our experience, new A2L rated, manufacturer engineered systems are safer and more reliable than piecemeal retrofits. Never mix refrigerants, it is like putting diesel in a gasoline car. On costs, refrigerant price may rise, but labor usually dominates the bill.

Safety & Maintenance: A2L Handling, Technician Training and Homeowner Limits

R454B and R32 are A2L refrigerants, low GWP and mildly flammable. Safe operation depends on keeping ignition sources away during charging, recovery, or any suspected leak, and following ventilation and charge limits in small rooms, closets, or attics. Cylinders must be stored in ventilated areas, out of direct sun and heat, below 52°C, and never kept at a residence. Refrigerants must not be mixed or vented, and R 410A systems and oils are not compatible with A2Ls.

- Homeowner tasks: replace or clean air filters, keep the outdoor unit clear, power off and gently rinse exterior coil fins, and visually check the condensate drain.

- Professional only: any work on the refrigerant circuit or energized internals, including handling, storage, recovery, charging, leak checks, opening sealed circuits, replacing refrigerant side parts, and electrical diagnostics inside panels.

In practice, safe ownership means homeowners handle housekeeping and monitoring while licensed, A2L trained technicians perform refrigerant, electrical, and combustion work.

Supply, Availability and Business Impacts for Contractors and OEMs

OEMs are rolling out A2L platforms in waves by model family and region, with early allocations tight and R-410A overlap during the ramp. We have seen lead times swing quickly, so treat this as a staged conversion. Lock forecasts early, place quarterly POs, and carry 4 to 8 weeks of safety stock on coils, air handlers, and common tonnages. Segregate A2L inventory and update hazmat shipping procedures. Tool up with A2L-rated recovery, manifolds, leak detection, and cylinders, and train techs on charging and ventilation practices. Audit SKUs for valves, controls, and oils that change with A2L platforms.

Moving Forward: Practical Next Steps for Contractors and Homeowners

R454B and R32 are the near-term future of comfort cooling: they deliver modern efficiency with much lower GWP than R 410A, provided systems are purpose-built and installed by A2L-trained techs. For contractors, the playbook is clear: get certified on A2L handling, update recovery and leak detection gear, align with manufacturer charge limits and local codes, and plan inventory around R454B and R32 platforms. For homeowners, start with an equipment inventory, weigh repair versus replacement at major failures, and prioritize matched systems that meet or exceed SEER2/EER2/HSPF2 baselines. Avoid ad-hoc refrigerant retrofits, and schedule a pre-season consult so you are not making decisions in a heat wave. Our team has 30+ years in HVAC and has fulfilled 200,000+ orders, so we can recommend factory-engineered packages that cut operating costs and keep you compliant.

- Get a Custom Quote: right-sized R454B or R32 systems, wholesale pricing, financing with Affirm.

- Talk to Our Team: U.S.-based phone support for load sizing, code questions, and product selection.

- Shop Heat Pumps and Central AC: R454B and R32 units with full manufacturer warranties and free shipping on most systems.

hvac systems

hvac systems

Cooling

Cooling Heating

Heating Learning Center

Learning Center Money Saving Tips

Money Saving Tips Product and Brands Insights

Product and Brands Insights Buying Guides

Buying Guides State by State

State by State