Why Lifetime Operating Cost Matters When Choosing a Heat Pump

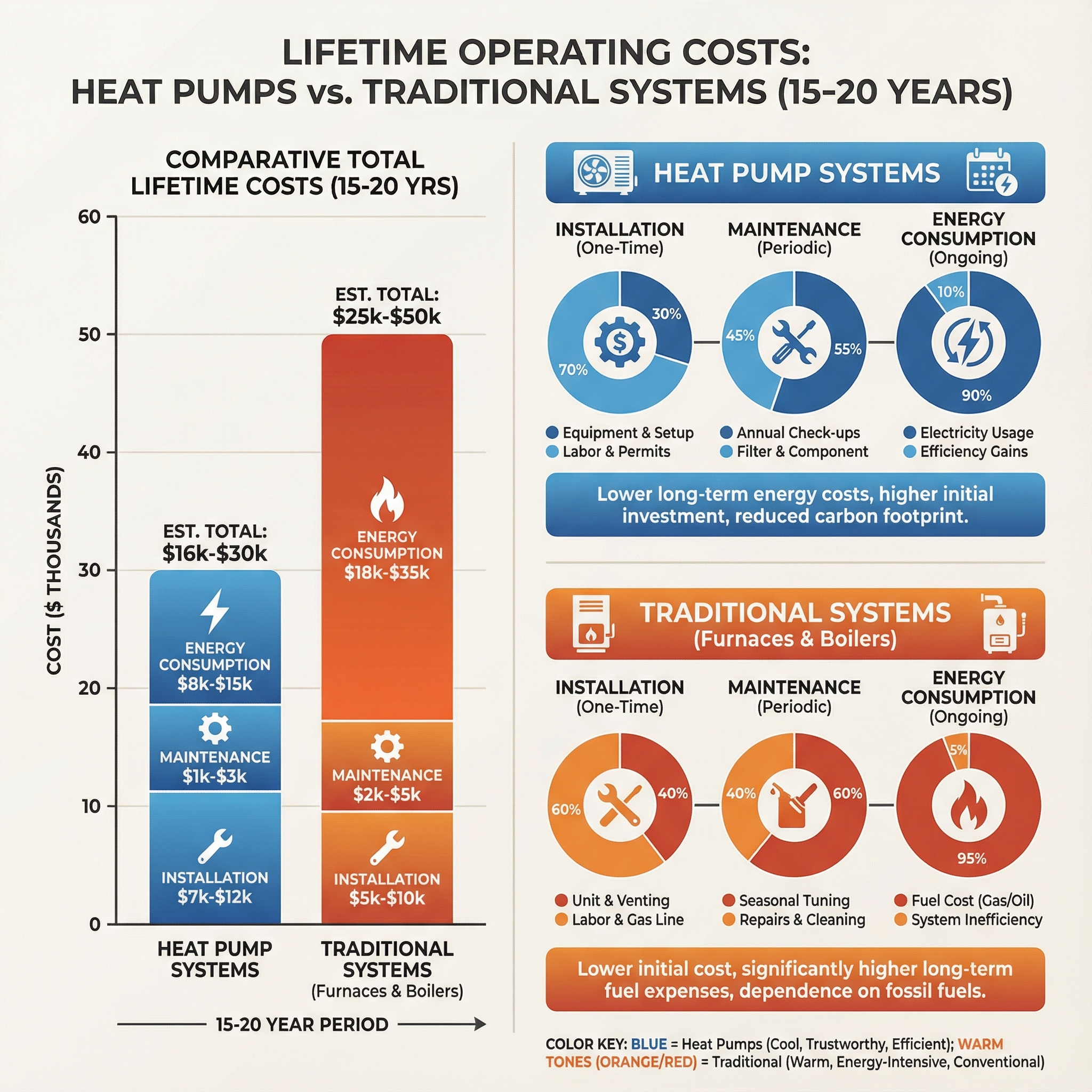

When comparing a heat pump to traditional HVAC, the real decision is total cost of ownership over the life of the equipment, not just the lowest installation bid. Heat pumps can cost more upfront, yet they often deliver lower monthly utility bills and more stable long run costs.

The reason is structural. A heat pump moves heat instead of creating it. Think of it like using a dolly to roll a heavy fridge across the floor rather than lifting it. Electric resistance heaters and many combustion systems generate heat from scratch, which demands more energy. By transferring heat from outdoors to indoors in winter, and reversing that process in summer, a heat pump does the same job with less input energy.

That efficiency advantage shows up every month. The gap between moving heat and generating it compounds season after season, so the operating side of the equation often outweighs the initial price difference. Framing your choice around lifetime operating cost gives a clearer picture of what you will actually spend to stay comfortable.

Which Systems We're Comparing: Heat Pumps vs Furnaces, Boilers and Electric Resistance

Heat pumps move heat using a refrigeration cycle: a compressor circulates refrigerant through coils, carrying heat like a conveyor. A reversing valve flips the flow so the same appliance cools in summer and heats in winter. Compared with electric resistance, they deliver about 2 to 4 times more heating or cooling per unit of electricity. Furnaces and boilers are combustion, heat-only systems that need a separate AC. High SEER2 and HSPF2 units can save several thousand dollars over time versus minimum models. Upfront cost is higher than a basic furnace, but rebates often shrink the premium.

How We Calculate Lifetime Operating Cost: A Practical Homeowner Checklist

Use this checklist to compare options apples to apples and avoid costly surprises over 15 to 20 years.

- Clarify priorities: comfort, lowest upfront, lowest long term cost, carbon goals, backup heat needs.

- Collect home and climate basics: square footage, insulation and air sealing condition, duct size and leakage, window quality, indoor setpoints, local design temperatures.

- Require Manual J (loads), Manual S (equipment selection), and Manual D (duct sizing) from every bidder.

In our experience at Budget Heating (BudgetHeating.com), the biggest misses are skipping Manual J and not validating AHRI matches, which can swing lifetime cost by thousands.

- Gather utility prices: electricity $/kWh with tiers or time of use, any demand charges, gas $/therm, propane or oil $/gal, delivery fees and taxes.

- Model scenarios: standard heat pump, cold climate heat pump, furnace plus AC, and a baseline keep running case.

- Verify AHRI matched system ratings for the exact indoor and outdoor pair. Think of AHRI as the recipe card that confirms the ingredients belong together.

- Estimate annual energy use and cost, then run sensitivity at ±20 to 30 percent fuel price swings.

- Include incentives, routine maintenance, filter and tune up costs, expected replacement timing, and any duct repairs or resizing that affect efficiency.

Energy Cost Comparison: Electricity vs Natural Gas vs Oil: Real Numbers and Ranges

Annual utility costs depend on your baseline system and local rates. Across regions we supply, typical totals are:

- Electric resistance heat with central AC: about $1,200 to $1,800 per year.

- Natural gas furnace with AC: about $1,500 to $2,250 per year.

- Oil or hydronic boiler and radiators: about $1,800 to $2,700 per year.

Switching to a heat pump typically saves $300 to $1,500 per year. Installed cost is often $3,000 to $5,000, with incentives lowering the net. Annual maintenance runs $100 to $300. Simple payback ranges from roughly 2 to 17 years. Savings are highly sensitive to local energy prices, like buying the same grocery cart at different stores: low electric rates or high gas prices widen the gap, while cheap gas or high electric rates narrow it. Time of use plans and climate also shift the math.

When a Heat Pump May Not Be the Best Choice: Honest Tradeoffs and Alternatives

We install and ship a lot of heat pumps, yet there are cases where another path fits better. Two things to understand up front: in deep cold, standard models lose capacity and need backup heat, and the cost picture swings with climate and local fuel prices.

- Very cold regions with inexpensive natural gas: A 95 percent AFUE furnace can beat a standard heat pump on winter operating cost. Alternatives: high efficiency gas furnace with a matching AC, or a dual fuel setup that runs a cold climate heat pump above a set temperature and gas below it.

- Homes that lack electrical capacity for auxiliary heat strips: Backup heat requires sizable breakers, proper wiring, and controls that stage it correctly. If panel upgrades blow the budget, consider a gas furnace with AC, or dual fuel to minimize strip heat use.

- Spaces that demand very hot supply air to feel comfortable: Some occupants prefer short, high temp blasts. A furnace often delivers that sensation better than a moderate supply temp heat pump.

Common pitfalls: assuming heat pumps always cost more than gas, believing they do not work in cold climates, treating all electric heat as resistance, and skipping lifetime cost and installation quality. SEER2 and HSPF2 ratings and local rates drive outcomes.

Key Efficiency Metrics (SEER2, HSPF2, COP, AFUE): What They Mean for Bills

SEER2 and HSPF2 are seasonal efficiency ratings for cooling and heating, similar to miles per gallon. In 2023 SEER2 replaced SEER, and labels read lower even when performance is unchanged. Typical tiers: minimum 14.3/7.5, ENERGY STAR 15.2/7.8, best 24/11. DOE/FEMP modeling shows annual use around 11,352 kWh for minimum units, 10,743 kWh for ENERGY STAR, and 7,029 kWh for the best, which totals roughly $13,595, $12,866, and $8,418 over 15 years. In our experience at Budget Heating (BudgetHeating.com), stepping up one tier often saves hundreds per year and several thousand over a system life. COP and AFUE are also used, but bill estimates rely most on the seasonal SEER2/HSPF2.

Annual Maintenance, Safety and Repair: What to Budget and When to Call a Pro

From years in the field, we keep homeowner maintenance simple: replace or clean filters, keep registers clear, maintain open space around outdoor units, check the condensate drain, and test safety detectors. Think of it like an oil change, small steps that protect the system.

Call a licensed pro for electrical troubleshooting, refrigerant or sealed system work, combustion inspections on furnaces or boilers, and immediately for any gas smell or a CO alarm.

Service heat pumps at least annually, twice in heavy use climates, and budget about $100 to $300 per year for routine care. Schedule furnaces and boilers annually before heating season. Inspect and seal ducts periodically to preserve efficiency and comfort.

Red flags that raise costs or risk include neglected filters, blocked registers, overgrown outdoor units, a clogged condensate drain, or any safety alarm. Addressing these early prevents small issues from becoming major repairs.

Brand & Product Choices That Affect Lifetime Costs (What to Ask Contractors)

When comparing brands and lines, focus on what will protect your wallet over the full life of the system. Ask about: variable speed compressors and blowers for smoother operation with fewer starts, warranty length, labor options and transfer rules, parts availability and serviceability, coil corrosion protection, sound levels, compatibility with simple controls, and required maintenance. Clarify defrost strategy, crankcase heat use, and whether proprietary boards raise repair costs.

Practical Tips to Lower Lifetime Operating Costs (Maintenance, Controls, and Incentives)

Start with commissioning: verify target airflow per ton, correct refrigerant charge, and safe static pressure. In our field work, a tuned system runs fewer hours and avoids expensive electric resistance heat. Seal and insulate ducts so paid air reaches rooms. Choose variable speed equipment and pair it with a smart thermostat: use low speeds in mild weather, tight setback schedules, and humidity control to reduce runtime. Limit resistance backup with outdoor lockout and staging. Finally, claim rebates and tax credits to cut net installed cost and speed payback.

Bottom Line: Which Homes Benefit Most from Heat Pumps (and How to Decide)

Bottom line: in most mild or moderate climates, a properly selected and installed heat pump beats electric resistance, baseboard, and many gas or oil systems on lifetime cost and emissions. Your best fit depends on efficiency, local power vs fuel prices, climate, installation quality, and other costs. If you plan to stay 15 to 20 years, the math often favors a heat pump. Not sure how to model it for your home? Our U.S.-based team will run the numbers with you.

- Get a Custom Quote

- Talk to Our Team by phone for fast, U.S.-based advice

- Shop Heat Pumps at wholesale pricing

- Shop Ductless Mini Splits