When Should I Add a Hard Start to My Central Air Conditioner?

If your air conditioner hesitates at startup, hums without kicking on, dims the lights, or occasionally trips a breaker, a hard start kit could be the assist your compressor needs. It provides a short burst of extra torque at startup, similar to a sprinter using starting blocks, helping the compressor overcome initial resistance and get up to speed more cleanly.

This guide is for homeowners and DIYers who are troubleshooting start problems or weighing a simple, low-cost life extension for an older unit. We explain what a hard start kit can and cannot do, when it is worth installing, and how to decide safely and confidently. We will cover:

- Clear signs that point to a hard start kit as a good option

- Conditions where a kit helps, and situations where it will not

- Compatibility basics across common residential systems

- Costs to expect and value tradeoffs

- Installation considerations, safety, and warranty implications

- When the symptoms call for professional diagnosis instead

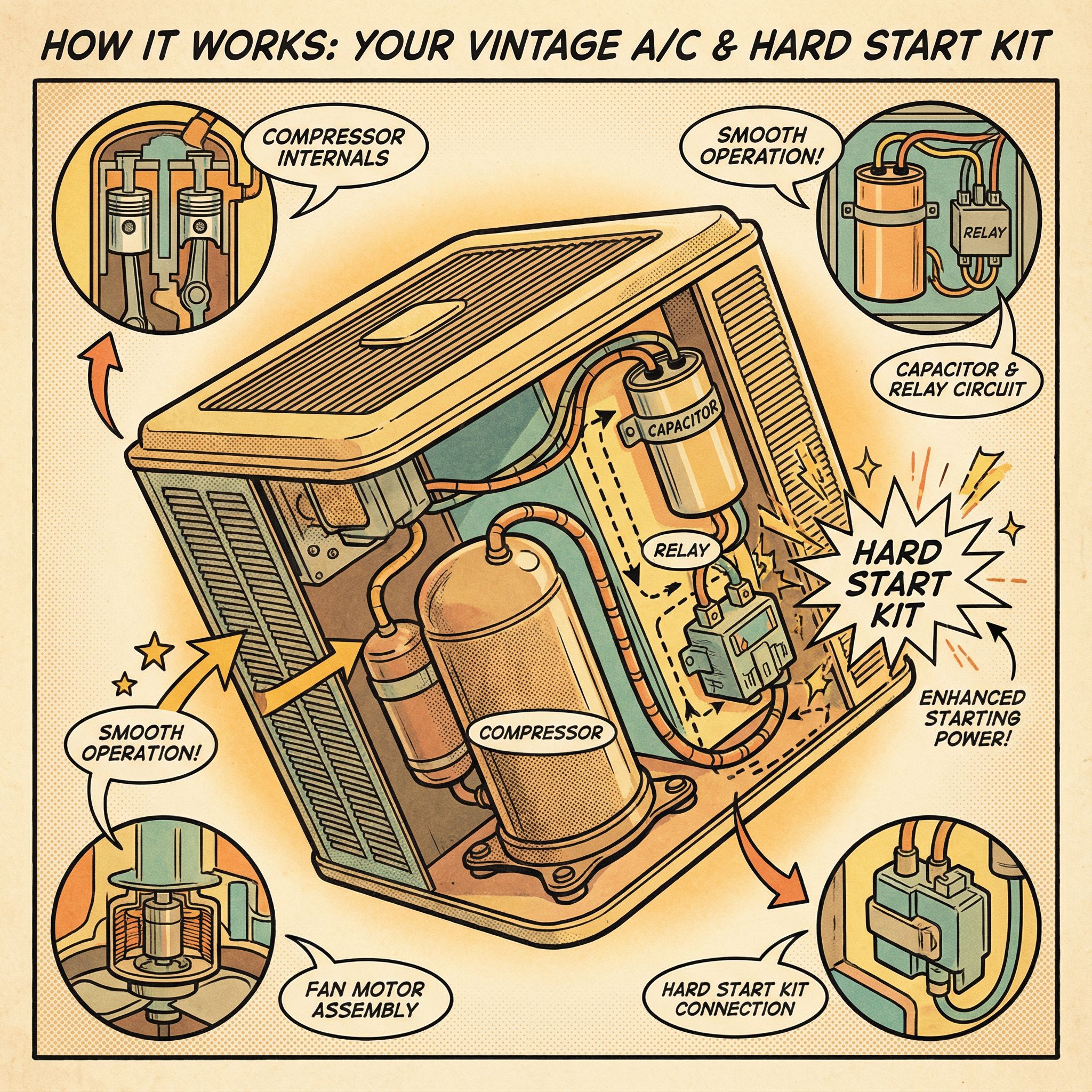

What a Hard Start Kit Is and How It Works

In our field experience, a hard start kit is an add-on start-assist device for single-phase central AC and heat pump compressors. It delivers a brief increase in starting torque or reduces the initial inrush current, helping the compressor reach operating speed faster.

Think of it like a quick, firm push to get a heavy cart moving. The assist is momentary, only during startup, then the system runs as usual. By helping the rotor accelerate quickly, the compressor spends less time in the toughest part of startup, where electrical demand and mechanical load are highest. That translates to a faster, smoother spin-up.

The practical benefits show up right at startup:

- Smoother, faster compressor starts.

- Reduced mechanical and electrical stress on the compressor and the contactor.

- Fewer nuisance issues on marginal systems, such as breaker trips or lights dimming when the unit kicks on.

In short, a hard start kit changes the first seconds of operation, trimming the high-stress interval so the compressor can get up to speed cleanly and reliably.

Common Signs Your AC Needs a Hard Start Kit

After 30+ years working on residential systems, we see hard starting show up in a few repeatable ways. Try these simple checks during startup, much like listening to a car that struggles to crank:

- Humming or buzzing at startup that lasts a second or two before the compressor actually turns.

- The outdoor unit starts then quickly shuts off or stalls, sometimes trying again after a pause.

- Repeated clicking during start attempts from the contactor or control board.

- A breaker trip that happens exactly when the compressor tries to start.

- Noticeable whole-home light dimming or flicker the instant the AC kicks on.

If starts are clean and quick with no flicker, dimming, or trips, a hard start kit usually offers little benefit. Reserve start assist for verified hard start symptoms, not as a universal upgrade. These checks help you avoid unnecessary parts and point to a real starting issue when it exists.

Situations That Warrant Adding a Hard Start (age, voltage issues, frequent restarts)

Certain real-world conditions make compressors work harder at startup. In those cases, a hard start kit is a smart assist that reduces strain and helps the unit get moving cleanly.

- Aging systems (often 10+ years): wear increases starting torque, so a kit can buy time while you plan a replacement.

- Marginal power: 208 V service or noticeable voltage sag at startup (lights dimming) are classic triggers.

- Long line sets or high vertical lift: long runs or rooftop condensers raise start load on the compressor.

- TXV or other expansion-valve systems: added initial restriction increases the effort required to start.

- High static pressure ductwork: restrictive or undersized ducts elevate head pressure right at startup.

- Hot, humid, or storm-prone regions: hot restarts, outages, and surges make reliable starting more difficult.

- After a power event: if a surge or outage stressed the capacitor but the compressor is still sound, a kit helps it restart.

- Newer single-stage units without factory start assist: when the manufacturer allows it, an approved kit reduces wear in tough or low-voltage installs.

- Frequent restarts: if your system cycles back on quickly, easing each start reduces cumulative stress.

In our experience at Budget Heating (BudgetHeating.com), 208 V services and long line sets are among the most common drivers for adding start assist.

DIY vs Professional Installation: Safety Steps and What to Expect

There are a few homeowner-safe steps that help without risking the system. Replace or clean air filters, clear leaves and grass from the outdoor condenser, gently rinse the coil fins from the inside out, and verify thermostat settings. Always shut off power at the outdoor disconnect and the breaker before any cleaning, and do not open electrical compartments. Think of this like washing a car, not rebuilding the engine.

Stop and call a licensed pro if you see severe light dimming on startup, frequent breaker trips, or suspect low supply voltage. Those issues need an HVAC technician and often a licensed electrician. Ice on lines or any suspected refrigerant leak must be handled by EPA certified technicians. Proper diagnosis requires measuring locked rotor amps, checking startup voltage sag, testing run or start capacitors, and assessing the contactor with the right meters and procedures.

- What are the measured LRA and startup amps?

- Are the run capacitor and contactor within spec?

- Is any recommended kit approved by the manufacturer?

- Will that kit fix the root symptom?

- How does the kit cost compare with the system's expected remaining life?

When a Hard Start Kit Is Not the Right Fix (Limitations & Alternatives)

In our experience, a hard start kit is not a cure all. On older, marginal compressors it can be a targeted, life-extending stopgap to buy time, not a long-term substitute for the real repair.

- Electrical parts are failing: If the run or start capacitor is weak, or the contactor is burned, test and replace those parts first. A kit will not compensate for failed components.

- Wiring or power issues: Miswired equipment or an undersized circuit needs correction at the source. Do not mask supply problems with a kit.

- Refrigerant or airflow faults: Low charge, leaks, or poor duct design cause hard starting. Repair leaks, set the correct charge, and correct duct or airflow restrictions.

- Internal compressor damage: If the compressor is mechanically compromised, a kit will not revive it. Plan for compressor replacement.

- Incompatible equipment: Do not add third-party kits to variable-speed or inverter systems, or units with factory soft-start or engineered controls. OEM methods are typically required and aftermarket kits may be prohibited under warranty or listing.

- Common myths to skip: Not every AC needs a kit, it is not a permanent fix, it does not meaningfully raise SEER or efficiency, and flickering lights or breaker trips do not automatically mean a kit is the answer.

Hard Start vs Soft Start: Which Start Assist Is Right for Your System?

Think of a hard start as a jump starter for a single phase compressor: it uses a capacitor and relay to deliver a quick torque boost at startup. A soft start or inverter control acts more like a dimmer switch, ramping speed and current smoothly to reduce mechanical stress and lights flicker. Many high efficiency systems already include multi stage or variable speed compressors with factory ramping, and third party hard start kits are often unnecessary or even prohibited because they can conflict with the onboard electronics. In our experience at Budget Heating (BudgetHeating.com), following the manufacturer's path here prevents headaches and warranty issues.

Regulatory note: SEER2 test changes apply to new equipment sales, not accessories, and adding a hard start does not change a unit's certified SEER or SEER2 rating. Choose OEM approved soft start solutions for inverter or factory soft start equipment. Use aftermarket hard start kits only on single phase, non variable systems when the manufacturer allows it, and match the kit to the compressor model.

Benefits, Costs, Lifespan and Warranty Considerations for Hard Start Kits

In our experience, hard start kits are simple, low cost add-ons that help a compressor spin up, like giving a heavy door a brief push at the start. Installed costs are modest compared with replacing a compressor or a system. Do not expect utility savings, the kit only affects the startup window. The value shows in reducing service calls and helping a marginal compressor start reliably so you can schedule repairs or plan a replacement.

Lifespan is variable, treat the kit as a consumable helper rather than a permanent fix for a failing compressor. Check warranty language before you add start assist, some manufacturers specify exact devices and may deny coverage if an unauthorized kit is installed. Installation is not just a wiring swap, professionals de-energize equipment, verify zero voltage, and discharge capacitors. Using the wrong kit or miswiring can damage the compressor or create shock or fire risks.

How to Choose the Right Hard Start Kit for Your Compressor

We start by confirming the kit aligns with the compressor's needs: follow OEM part numbers and the unit's LRA and tonnage. Before installing any kit, we verify the electrical backbone is sound. Measure supply voltage at the condenser during startup and note any sag. Confirm breaker size and wire gauge match the nameplate MCA and MOP. For installation, a pro will de-energize and lock out power, discharge capacitors, mount the kit securely inside the condenser, and follow the wiring diagram. Afterward, we confirm reduced inrush or start amperage with a meter and smoother pull-in. Think of it like jump assistance for a stiff engine, then check that the engine now cranks easily. To protect start components, consider whole-home or dedicated HVAC surge protection and re-check startup each cooling season.

Should You Add a Hard Start Kit? A Practical Recommendation and Next Steps

Add a hard start kit only when the compressor struggles to start after capacitors and contactors are verified good, and the compressor tests sound. Do not use one to mask mechanical or electrical faults, severe refrigerant issues, or on variable speed or inverter units with OEM soft start.

If you notice humming, slow spin up, nuisance breaker trips, or lights dimming, the right OEM approved kit can trim inrush amps and smooth starts. After basic maintenance, have a licensed tech measure start amps and confirm the correct kit or the proper repair path. Not sure? We can guide you.

- Get a Custom Quote, sized to your model and application.

- Talk to Our Team, U.S. phone support with 30+ years in HVAC.

- Shop Hard Start Kits, wholesale pricing, many items ship free, Affirm financing.