Why Heat Exchange Is the Core of Modern Gas Furnace Performance

After decades installing and troubleshooting systems, we treat a modern gas furnace as a controlled heat exchange machine. Fuel burns inside a sealed combustion chamber, hot flue gases move through a metal heat exchanger, and your indoor air passes over the outside of those metal walls to pick up heat. The two air streams never mix, so combustion byproducts, including carbon monoxide, stay out of your living space. That separation is safety. How effectively those metal surfaces move heat into the airstream drives efficiency and, in turn, steadier comfort and lower fuel use.

This article sets the table for smart decisions: what heat exchangers are made of and why material choice matters, how blower-driven airflow and duct pressure influence heat transfer, the practical differences between non condensing and condensing designs that reclaim more heat from exhaust, and how efficiency metrics fit in. AFUE explains furnace heating performance, while SEER applies when comparing matched cooling components in a complete system. Understanding heat exchange clarifies where comfort, safety, and cost intersect.

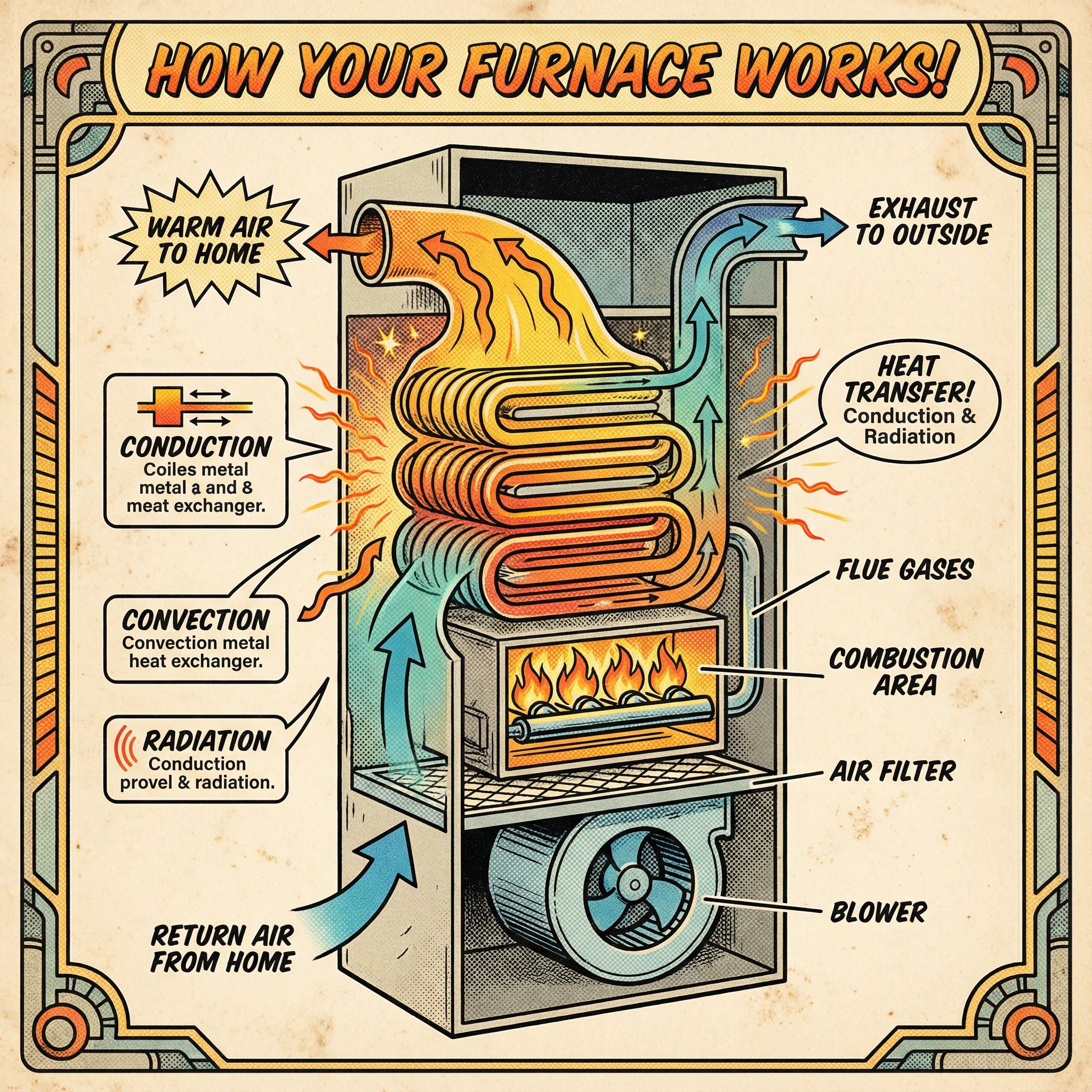

Heat Transfer Fundamentals: Conduction, Convection and Radiation in Furnace Design

Inside a furnace, heat moves three ways. Combustion raises flue gas temperature, then heat conducts through the heat exchanger wall into the indoor airstream. The warmed metal transfers energy to moving air by forced convection, and a smaller share radiates from the hot surface, most noticeable before airflow ramps up. To boost transfer without mixing air and flue gas, designers add surface area with tubular or multi pass paths, sometimes fins, use counter flow that keeps the hottest gas next to the coolest air, and lengthen gas residence time. Stainless or aluminized steel survive high heat, repeated cycling, and corrosive condensate. Steady airflow is essential, so variable speed blowers and multistage gas valves smooth heat input and limit thermal stress.

Efficiency Metrics and Heat-Exchanger Design: AFUE, BTU and Heat Recovery Explained

AFUE tells you what share of the fuel becomes heat for the home over a season, while SEER/SEER2 apply to cooling. BTU is the heating output size, not efficiency. Pairing the right BTU with a higher AFUE is what trims fuel bills.

Non-condensing furnaces typically land near 80% AFUE because they vent hot flue gases. Condensing models add a secondary heat exchanger that cools exhaust below the dew point, capturing latent heat, like wringing a damp towel. That design routinely delivers 90 to 98% AFUE. In our experience at Budget Heating (BudgetHeating.com), the details matter: larger surface area, multi-pass or counter-flow paths, and corrosion-resistant materials keep efficiency high and durable. Ongoing DOE minimums are moving more homes to condensing units, which means lower stack temperatures and less fuel burned for the same BTUs indoors.

Sizing, Installation and the Long-Term Impact on Heat-Exchanger Life

Correct sizing, ductwork, venting and commissioning determine how long a heat exchanger actually lasts. A furnace that is too large short cycles like a sprinter, which repeatedly heats the exchanger without letting temperatures stabilize. The right size runs steady cycles so the exchanger reaches its designed temperature rise without stress. Airflow and combustion must be proven with readings, not guesses. High static pressure, low blower CFM or improper gas pressure can push temperatures out of the safe zone and shorten exchanger life. In our experience at Budget Heating (BudgetHeating.com), the commissioning sheet is what separates a smooth install from recurring service calls.

- Require a Manual J load calculation and avoid oversizing. A right-sized furnace reaches the designed temperature rise.

- Seal and insulate ducts. Have static pressure and temperature rise measured and documented.

- Verify correct manifold gas pressure, proper venting, and condensate handling.

- For condensing units, confirm the condensate trap, neutralizer, and PVC venting are installed correctly.

- Ask for commissioning data: measured static pressure, blower CFM, manifold gas pressure, combustion analysis, and a written Manual J or Manual S.

Maintenance, Inspection and Safety: Protecting the Heat Exchanger and Your Home

The heat exchanger is a barrier that keeps flue gases out of your air. If it cracks or corrodes, carbon monoxide can reach the living space. We verify safety with visual checks, combustion analysis, temperature rise readings, soot or moisture clues, and by confirming venting and condensate flow. If you smell gas or a CO alarm sounds, evacuate and call professionals.

- Homeowner: change or clean filters every 1 to 3 months, keep grilles clear, keep vent terminations open, maintain CO detectors.

- Licensed technician: combustion analysis and burner tuning, heat exchanger inspection, venting and condensate service. Annually include checks for corrosion, cracks, soot, temperature rise, blower cleaning, and condensate maintenance.

Cost, Savings and Where Efficiency Pays Off: Realistic Payback Estimates

Moving from an 80% furnace to a 95% AFUE model trims fuel use about 16%. Jumping to 98% saves roughly 18%. If your winter gas spend is $1,200 on an 80% unit, a 95% upgrade saves about $192 per year and 98% saves about $216. Condensing options commonly run 90-98.5% AFUE.

Cooling follows the same math: going from SEER 10 to SEER 15-16 cuts energy roughly one third. If you use 3,000 kWh each summer, that is about 1,000 kWh saved, or $150 per year at $0.15 per kWh. Payback speeds up in colder climates with more heating hours, or in hot climates for AC upgrades. Installation quality can make or break those gains. In our experience at Budget Heating (BudgetHeating.com), the quickest paybacks come where usage is high. By late 2028, many classes will require 95% AFUE minimum, shifting pricing and options.

When a Gas Furnace Heat Exchanger Isn't the Best Choice (Tradeoffs and Alternatives)

Climate and regulations shape the call. With the U.S. moving to a 95% AFUE minimum for many furnaces by late 2028, condensing models become the norm, which adds venting and condensate needs. In our field work, that is not ideal everywhere. Think of matching the drivetrain to the terrain, not every house or climate wants the same engine.

- Mild climates: A heat pump first approach or high SEER2 cooling delivers better daily value, since heating loads are light most of the year.

- Mixed climates: Dual fuel often wins, the heat pump covers typical weather, the gas furnace steps in for cold snaps.

- Retrofits with venting or drain limits: Older homes or interior apartments may struggle with condensing installs, a heat pump avoids flue routing and condensate lines.

AFUE and payback specifics matter, but start with climate, code timelines, and installation realities.

Common Myths and Installation Mistakes That Harm Heat-Exchange Performance

We regularly correct a few misconceptions that quietly hurt efficiency and reliability. Think of the heat exchanger like a kettle wall, flame on one side, room air on the other.

- The furnace mixes combustion gases with indoor air: false. The exchanger is a sealed barrier that keeps streams separate when intact.

- Hotter flame means higher efficiency: false. Efficiency comes from pulling more heat out of the exhaust and transferring it to the indoor air.

- Metal choice does not matter: false. Stainless or aluminized steel handle corrosion and thermal stress better, so performance stays stable longer.

- Closing supply vents saves energy: false. It raises duct pressure, cuts airflow, and can stress or overheat the exchanger.

- Bigger is better: false. Oversizing drives short cycling, weak heat transfer, and premature wear.

- Maintenance is optional: false. Heat exchangers are not maintenance free, annual inspections are essential.

Framing the Science: What ‘The Science of Heat Exchange' Means for Buyers and Specifiers

After three decades in the field, we start every furnace conversation the same way: a furnace is a heat-exchange system. Picture a kettle on a burner. The goal is to move heat into the air stream with as little waste and stress as possible. That is why AFUE on the heating side and the matched system's SEER or SEER2 on the cooling side matter. They describe how effectively the equipment transfers heat per unit of fuel or electricity.

Key tradeoffs to compare: exchanger material and shape, airflow, and install quality. Aluminized steel is common and cost effective. Stainless resists condensate and corrosion, a better fit for high efficiency condensing units, and can stretch life toward 20 to 25 years versus a typical 15 to 20. Tubular or serpentine geometries distribute heat and reduce crack risk. Correct gas pressure, venting, and static pressure protect that performance over time.

Choosing the Right Heat-Exchange Strategy for Performance, Efficiency and Longevity

Modern gas heat is all about efficient, safe heat exchange. Condensing furnaces use a secondary exchanger to pull latent heat from the flue, pushing AFUE into the 90 to 98 percent range. Real-world results depend on exchanger materials and geometry, right sizing, proper venting, and routine maintenance.

- Request a Manual J load calculation

- Choose robust exchanger materials and a solid warranty

- Insist on combustion numbers and a commissioning report at startup

- Verify venting and condensate management

- Maintain filters, schedule annual service, and use CO detectors

Choosing a furnace is a big decision, and the specs can feel overwhelming. Our team can translate your home's needs into the right equipment and a clean commissioning plan.

- Get a Custom Quote

- Talk to Our Team, including real phone support

- Shop High Efficiency Gas Furnaces