HVAC Guide: Why Understanding Systems, Terms, and Refrigerants Matters

This guide is for homeowners, property managers, and anyone comparing quotes who wants clear, practical answers. We unpack the language behind heating and cooling so you can make confident decisions that affect comfort, monthly costs, indoor air quality, and code compliance.

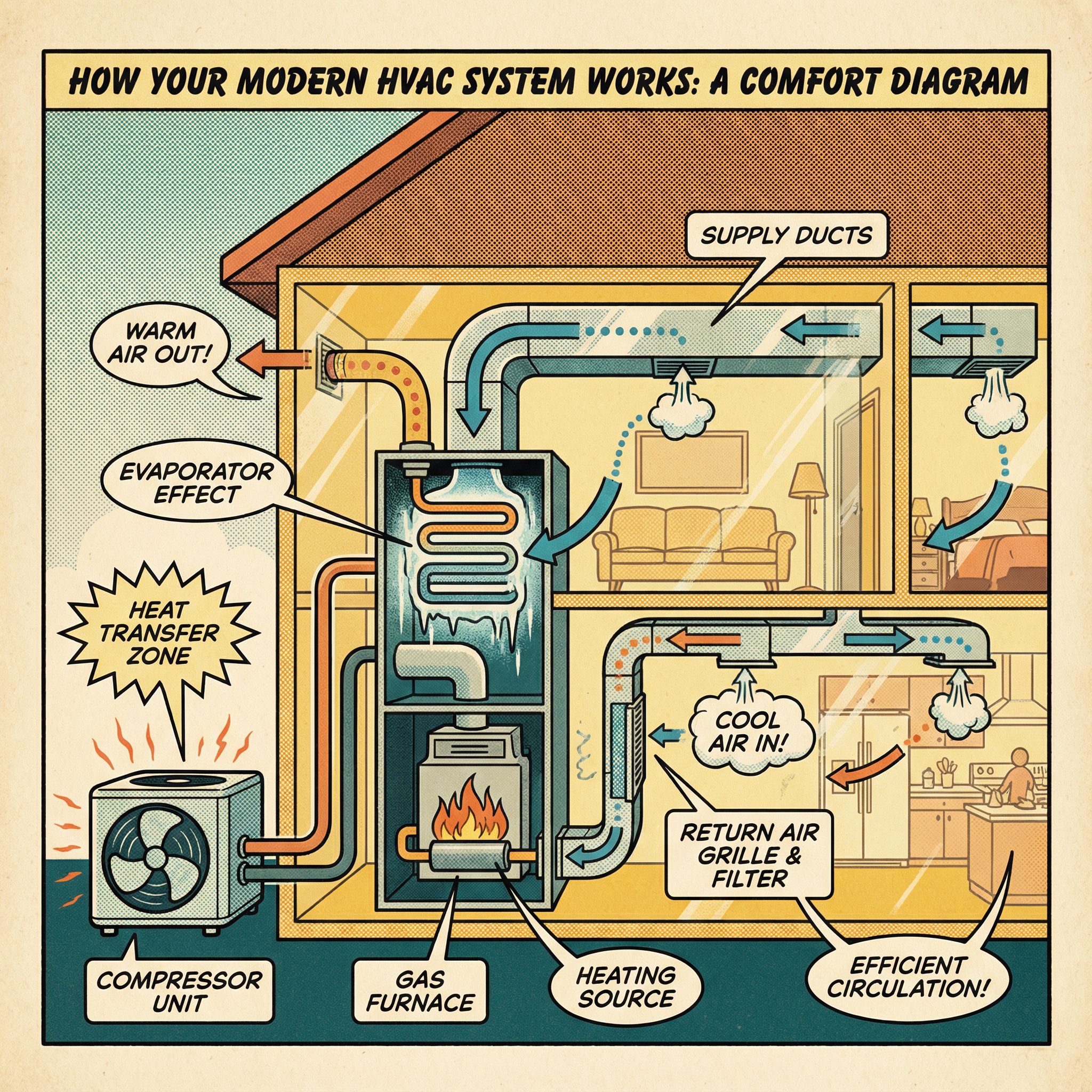

You will learn the ratings you see on labels and proposals: BTU and tonnage for capacity, SEER2 and HSPF2 for efficiency, AFUE for furnace performance, plus CFM and MERV for airflow and filtration. We compare the main system types and how they operate in real homes and light commercial spaces: furnaces with central AC, all electric heat pumps and ductless mini splits, packaged units, and VRF or VRV.

We also demystify refrigerants and current rules, from the R 22 phaseout to R 410A, R 32, and lower GWP options, and what that means for serviceability and future costs. Think of sizing like picking the right shoes, too small or too big both feel wrong. The right match delivers steady comfort and longer equipment life.

HVAC Basics: Key Benefits, System Roles, and What to Compare

When you compare systems, start with efficiency ratings. SEER reflects seasonal cooling efficiency, EER shows a snapshot at very hot conditions, and HSPF measures a heat pump's heating-season efficiency. A simple memory aid: think of EER as an Extreme Efficiency Rating for peak heat, and HSPF as the heating-season counterpart to SEER. Higher numbers generally mean lower operating cost.

Capacity is the system's output. It is measured in BTU per hour, and 1 ton equals 12,000 BTU/h. In our field experience, right sizing matters more than rules of thumb. Oversized units short cycle, waste energy, and struggle with humidity control, while undersized units run constantly and still feel weak.

System types at a glance: a straight-cool air conditioner pairs with a furnace for heat, while a heat pump provides both heating and cooling. Both ACs and heat pumps use SEER and EER for cooling, and only heat pumps use HSPF for heating. In warm or moderate climates, heat pumps often pencil out well. In very cold areas or where gas is inexpensive, an AC plus furnace can be the better fit.

Refrigerant is the working fluid that carries heat, the blood of the system. Older units used R-22, now phased out for ozone damage. Most current equipment uses R-410A, and newer designs are moving to lower impact options like R-32 or blends. Refrigerant lives in a closed loop, so routine top offs are not normal. If it is low, there is a leak to fix.

Practical tips: compare models apples to apples with SEER, EER, and HSPF, match BTUs and tonnage to the home's actual load, value high EER in extremely hot regions, and consider refrigerant type and future rules as part of total ownership cost.

What This Guide Covers: Scope, Audience, and How to Use It

HVAC Guide: Key Terms, Systems, and Refrigerants Explained is written for readers who want clear, field-tested explanations without fluff. We designed it for:

- Students who need plain-language definitions and context for exams and labs.

- Entry-level technicians building a mental map of components, sequences, and metrics.

- DIY homeowners who want to sanity-check proposals and understand basics.

- Property and facility managers comparing system types and lifecycle implications.

How to use it: start with key terms to align on vocabulary, then connect those terms to system types, finally review refrigerants to understand compatibility and phaseouts. Read straight through if you are new, or jump to the section you need. We keep jargon light and highlight practical trade-offs we see on real installs so you can make confident, informed decisions.

Common Myths and Tradeoffs: When HVAC Options Aren't Ideal

We often see two patterns that derail good decisions. First, mistaking capacity for quality. Bigger is not better, it is like buying shoes two sizes up and hoping they fit. Oversized systems short cycle, miss humidity targets, and wear out faster. The right size comes from a proper load calculation, not a rule of thumb.

Second, mixing up ratings. SEER, EER, and HSPF are not interchangeable. Compare like to like, and if you live with long stretches of extreme heat, EER carries more weight than SEER on those toughest days.

Refrigerant myths are common. Refrigerant is not a consumable, adding charge signals a leak that needs repair. Freon usually means older R 22. Modern units use R 410A with a shift toward lower GWP options like R 32. Ozone safe does not mean harmless, venting still impacts climate, so recovery and tight installs matter.

- If ducts are leaky or undersized, high efficiency equipment will disappoint. Seal or resize ducts, or consider ductless mini splits.

- In very hot, arid regions, a high SEER but low EER AC can be costly at peak. Choose higher EER, or consider evaporative cooling where climate allows.

- For small additions or occasional-use rooms, extending central air is inefficient. A ductless mini split or a room unit fits better.

Energy Efficiency Explained: SEER2, EER2, HSPF2 and What They Mean for Bills

SEER and SEER2 tell you how efficiently an air conditioner or heat pump cools over a season. They measure total cooling output against total electricity used, think miles per gallon for comfort. Higher numbers mean the same cooling with less power. In 2023, SEER2 replaced SEER as the regulatory metric and uses the DOE M1 test, which adds more realistic external static pressure and tighter conditions. SEER2 values often appear lower than the old SEER for the same unit, but the rule holds true, higher SEER2 means lower seasonal energy use.

Minimums now key off SEER2. Many regions require at least 13.4 SEER2 for new central AC. Hotter Southeast and Southwest regions require more, roughly mapping to about 15 SEER for smaller systems under 45,000 Btu per hour and 14.5 SEER for larger units in the Southeast, with the Southwest also enforcing EER2 minimums for peak heat performance. Heat pumps follow updated national SEER2 and HSPF2 minimums rather than region splits. HSPF2 rates heating efficiency, while EER and EER2 show steady state efficiency at a specific high outdoor temperature.

What this means for bills, efficiency upgrades lower operating cost. Jumping from 16 SEER to 18 SEER is about a 12.5 percent gain. If an 18 SEER run costs $100, 16 SEER would have been about $112.50. Moving from roughly 14.3 SEER2 to about 16 SEER2 often trims cooling energy near 10 percent. In our experience at Budget Heating (BudgetHeating.com), the biggest gotcha is comparing SEER to SEER2, always compare apples to apples.

- Hot climates and long run hours see faster payback.

- Installation and duct quality can make or break real world results.

- In very hot regions, pair high SEER2 with strong EER2 for heat waves.

- In milder areas, high efficiency may be about quieter operation and better humidity control as much as savings.

Cost & Savings Data: What's Available (and What's Not)

There is no standardized cost or savings range available here. In our experience, pricing varies with region, equipment size, install complexity, duct or electrical work, labor rates, and rebates. To price your project, request two to three local, line-item quotes covering equipment, labor, permits, and extras, plus an AHRI match. For payback, divide incremental cost by annual bill savings using your utility rate and expected run hours.

Maintenance & Safety Notes: Where Detailed Guidance Is Missing

Detailed safety and maintenance instructions were not available in the materials provided. With 30+ years in HVAC, we treat that as a stop sign for DIY beyond light cleaning. Rely on official sources and certified professionals: use the product manual, manufacturer service guidance, and local code requirements, then have a licensed technician handle setup, checks, and final commissioning. A qualified pro can verify safe operation, document settings for warranty purposes, and confirm the system performs as specified when exact procedures are not supplied.

Homeowner Checklist: What to Inspect, Ask, and Track

- Define goals and constraints: list rooms with comfort or humidity issues, note your climate, fuel options, and electrical capacity.

- Choose a system path: split or packaged, ductless mini split for zoning or no ducts, central heat pump, or AC plus furnace. In cold regions, consider cold climate heat pumps or hybrid.

- Load and ducts: require ACCA Manual J, S, D, T. Target about 400 CFM per ton, keep static pressure within limits. Seal duct leaks with mastic or UL 181 tape and correct return sizing.

- Efficiency and comfort: compare SEER2, EER2, HSPF2 or AFUE. Favor inverter compressors and ECM blowers. Check dB ratings and ask about vibration pads or sound blankets.

- Refrigerant and commissioning: avoid R 22. Confirm R 410A or lower GWP options like R 32 or R 454B. If A2L, verify code compliance and training. Demand evacuation to 500 microns with a decay test and record weighed charge with superheat and subcool readings. In our experience at Budget Heating (BudgetHeating.com), jobs with documented commissioning data run smoother and cost less to own.

- IAQ and moisture: use MERV 8-13 filters that your blower can handle. In humid areas, enable dehumidification or add a whole home unit. In dry areas, consider a central humidifier. Tight homes may need ERV or HRV.

- Controls and zoning: pick a thermostat compatible with heat pumps, dual fuel, multi stage, and dehumidify calls. Use bypass less zoning per manufacturer guidance.

- Installation day quality:

- Outdoor unit: level pad, 12-24 inch clearance, elevate above snow, keep plants 2 feet away.

- Line set: correct sizing, fully insulated suction, nitrogen purge while brazing, pressure test, then evacuate.

- Condensate: proper trap and slope, float switch, secondary pan in attics, safe drain location.

- Electrical: correct breaker and wire, outdoor disconnect, consider surge protection.

- Data to record: supply and return temps, static pressure, CFM, superheat, subcool, amperage, thermostat programming.

- Maintenance schedule:

- Filters: check monthly, replace every 1-3 months as needed.

- Outdoor unit: keep coil clean and maintain 2 feet of clearance.

- Condensate: flush seasonally, test float switches.

- Pro tune ups twice a year to confirm charge, clean coils, test safeties, verify combustion or defrost.

- Ask every contractor: provide Manual J, S, D results and model numbers with ratings, refrigerant type and any special code needs, plan to fix duct issues, included comfort features, noise data, warranty terms and registration window, available rebates or tax credits with estimated operating cost.

- Keep on file: permits and inspections, AHRI certificate, model and serial numbers, startup and commissioning sheet, warranty registration, and a maintenance log.

Regulations & Refrigerant Phaseouts: What Owners and Contractors Need to Know

In 2023 the DOE moved from SEER/EER/HSPF to SEER2/EER2/HSPF2 under the M1 test. The lab setup is tougher, including higher external static pressure, so ratings are more realistic. Minimums also rose: split ACs are 13.4 SEER2 in the North, 14.3 SEER2 in the Southeast and Southwest for units under 45,000 Btu/h, and 13.8 SEER2 for larger sizes. The Southwest also applies EER2 minimums for high heat performance. Heat pumps saw a nationwide efficiency increase, not region by region.

Refrigerants are shifting. R 22 is phased out in new equipment. Most current systems use R 410A, which avoids ozone harm but has high GWP. The U.S. is phasing down high GWP HFCs, steering designs toward lower GWP options like R 32 and A2L blends such as R 454B. A2Ls are mildly flammable, so codes and installation practices are changing, and local approval must be verified.

Gas furnaces face a 95% AFUE minimum by December 18, 2028. Taken together, replacements should align with SEER2/HSPF2 baselines and the refrigerant transition to limit cost and compliance risk.

Conclusion: Next Steps, Maintain, Verify, and Choose Wisely

The right HVAC choice starts with load based sizing, the correct system type, and honest efficiency ratings like SEER2, EER2, AFUE, and HSPF2, because those drive comfort, operating cost, and lifespan. Keep airflow healthy with clean filters and coils, and remember that today's lower GWP refrigerants, many in the A2L class, require up to date codes and handling. If you need refrigerant work, leak repair, charge verification, or you suspect duct and static pressure issues, call a certified pro. Our team can turn this into a right sized, code compliant package at wholesale pricing, backed by full manufacturer warranties and U.S. based support.

- Get a Custom Quote: share home details and we return load based options with clear pricing.

- Talk to Our Team: call our U.S. based experts for sizing, refrigerant, and code questions.

- Shop Heat Pumps, AC Split Systems, and Ductless Mini Splits, with free shipping and Affirm financing.

- Need it fast: ship from our PA or TX distribution centers or arrange same day pickup.