Introduction: Horizontal Furnaces vs Traditional Systems: what this cost comparison will cover

Technical buyers often weigh a horizontal forced air furnace against upright furnaces, boilers, or radiant hydronic systems. The choice is bigger than initial price. It spans installed cost, utility spend, service needs, usable space, and expected life, all rolled into total cost of ownership.

Drawing on decades of field sizing, logistics, and after sale support, we define cost effective as the lowest lifecycle cost that still meets performance and code. This comparison covers:

- Purchase and installation, including duct modifications, venting, condensate handling, gas or electric service, and clearances

- Energy use by fuel type and efficiency ratings, plus typical operating hours

- Maintenance workload and failure risk, from annual service to parts availability

- Lifespan ranges and the timing of major repairs or replacements

- Space and access constraints, especially attics, crawl spaces, and tight ceilings

- Comfort and indoor air quality factors that affect runtime and complaints

Choosing by sticker price alone is like buying a car only for the window tag, you miss fuel, insurance, and maintenance. Lifecycle cost keeps the full picture in view and is the basis for a defensible procurement decision.

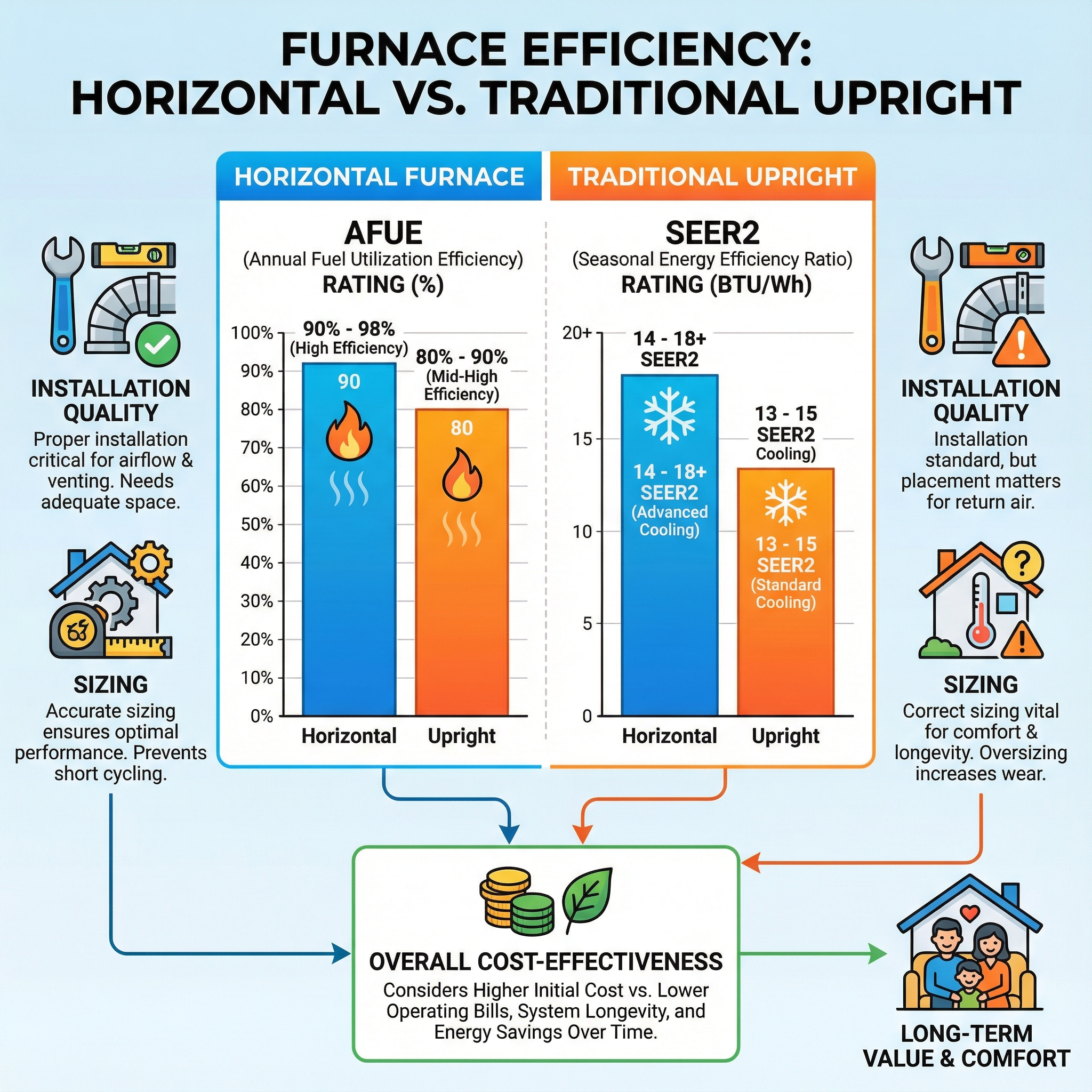

How horizontal furnaces work and why orientation alone doesn't change efficiency

A horizontal furnace is a forced-air gas unit built to operate on its side, typically in attics or crawlspaces. It uses the same core parts as an upright furnace, including the burner, heat exchanger, blower, and controls, just arranged in a different cabinet. In our field work, orientation by itself does not change AFUE, nor the SEER or SEER2 of matched cooling equipment. Think of it like turning a book sideways, the story stays the same. Real results come from the furnace's rated efficiency, proper sizing, tight ducts, and careful commissioning. Horizontal layouts shine where space is tight and gas service is available.

What we mean by 'traditional systems': forced air, boilers, and radiant options

Traditional systems covers upright forced-air furnaces with ductwork, hydronic boilers with radiators or baseboards, and in-floor or panel radiant heat. We compare them by distribution, efficiency, and installation complexity. Think of distribution like delivery routes: ducts move warm air, pipes move hot water, slabs or panels radiate heat into the space. Efficiency ranges widely. Modern high-AFUE furnaces and condensing boilers can match or exceed a horizontal furnace's operating efficiency, while older setups may be far lower. Radiant and hydronic options typically have fewer moving parts and very stable long term operation, but expect higher upfront work and cost for piping, manifolds, and in-floor loops.

Initial purchase & installation costs: components, labor and site prep to budget for

Upfront cost is driven by equipment, labor, and any duct, vent or drain work. To keep bids comparable, get at least two detailed quotes with identical scope: efficiency ratings, listed accessories, duct, vent and condensate work, commissioning steps, warranties, and a maintenance plan.

- Require model numbers and AHRI matched system IDs in writing.

- Sizing spec: Manual J load calculation, Manual S equipment selection, and Manual D duct design. Manual J determines your home's exact heat loss and gain, Manual S matches equipment to that load, Manual D sizes ducts for proper airflow. No rule of thumb sizing.

- Spell out duct modifications, sealing and insulation scope.

- For attic installs, include a secondary drain pan and float switch.

- Commissioning report must list combustion analysis, gas pressure, temperature rise, and static pressure.

- Include permits and old equipment disposal.

In our experience at Budget Heating (BudgetHeating.com), quotes that include the above avoid surprises and comfort issues. Note, horizontal furnaces tend to have moderate upfront cost, while hydronic or radiant systems often run higher due to piping and slab work.

Space, layout & infrastructure impacts: ductwork, venting, condensate and service access

Installed cost and operating efficiency are shaped by the space and layout as much as the furnace itself. In our experience, the duct system is the air's road network, and a poor route wastes fuel and comfort. Tight attics or crawlspaces also add labor for safe routing and code items.

- Ductwork: In unconditioned attics, ducts must be sealed and insulated. Leakage or poor design can erase the gains of a high-AFUE unit.

- Venting and condensate: Condensing furnaces need PVC venting with continuous slope, a condensate trap, freeze protection or heat tape where exposed, and a secondary drain pan with float switch in attics.

- Clearances and permits: Confirm manufacturer approval for horizontal left or right, maintain heat-exchanger and combustion air clearances, place vent terminations correctly, and obtain permits.

- Access: Provide service access, platforms or walkways, lighting, and code-required clearances.

- Electrical and gas: Verify circuits and a disconnect for ECM blowers and controls, and confirm gas line sizing, regulators, drip legs, and pressure testing before startup.

Key cost factors to compare: how to calculate total cost of ownership (TCO)

Total cost of ownership looks beyond the sticker price, similar to evaluating a car by fuel, insurance, and upkeep, not just the payment. TCO includes equipment purchase price, installation and site prep, energy use, routine maintenance, downtime and repair risk, expected service life and salvage value, plus any rebates or incentives. The lowest upfront price is often not the best value, since higher efficiency and better installation can pay back through lower monthly bills and fewer repairs.

Build a 10 to 15 year model: equipment + installation − rebates + energy + maintenance. Balance operating costs and initial investment carefully. Some traditional systems carry higher installation cost but can provide long run stability. Horizontal forced air typically pairs moderate upfront cost with strong daily efficiency when properly installed.

- Efficiency ratings: AFUE, SEER2, HSPF2.

- Local fuel and electric rates.

- Duct and distribution losses, especially in attics or crawlspaces.

- Correct sizing and climate load.

- Maintenance plan and access for service.

- Reliability profile and repair risk.

- Expected service life and possible resale or salvage value.

- Available rebates, tax credits, and utility incentives.

Energy efficiency & operating costs: AFUE, SEER2, HSPF2 and real world savings

AFUE rates furnace heating. SEER and SEER2 rate cooling for AC and heat pumps. HSPF and HSPF2 rate heat pump heating. Orientation does not change these ratings. In 2023 SEER2 and HSPF2 brought tighter tests and higher baselines, with regional SEER2 minimums and higher national thresholds for heat pumps.

- Cooling: SEER 10 to 13 can lower cooling cost about 20 to 25%. SEER 10 to 20 can approach 50%. A 15.2 SEER2 system typically cuts cooling cost 35 to 40% vs 10 SEER.

- Heating: 80% AFUE to 95% trims fuel use roughly 15 to 20%. Modern air source heat pumps often use about 50% less electricity than resistance heat.

In our experience at Budget Heating (BudgetHeating.com), correct sizing and pairing, not cabinet orientation, drive bills, so match a high AFUE furnace with a higher SEER2 AC or choose a high HSPF2 heat pump.

Maintenance, downtime & repair costs: real maintenance profiles and safety guidance

Horizontal forced-air furnaces, often installed in attics, include fans, burners and modern controls such as ECM blowers and staging. They benefit from annual professional tune-ups, plus extra checks on condensate pans and float switches to prevent water damage and surprise shutdowns. Think of the condensate pan like a shallow tray under an ice maker, if it backs up it overflows. Radiant or hydronic systems have fewer moving parts and may see fewer routine mechanical visits, but when concealed piping or components fail, repairs can be more disruptive and costly.

Typical professional furnace maintenance runs a few hundred dollars per year. Follow an annual cadence for both heating and cooling. Homeowner-safe tasks include:

- Replace filters every 1 to 3 months.

- Visually check condensate lines and pans.

- Keep registers clear.

- Test CO detectors.

- Shut off power before opening any service panel.

Stop and seek a licensed technician if you smell gas, a CO alarm sounds, you see visible soot, or persistent unusual noises occur. Always use a pro for refrigerant work, electrical diagnosis, combustion issues, repeated breaker trips, and any duct redesign or major installation work.

Tradeoffs & when each system is more cost-effective: honest scenarios and alternatives

From decades of installs, we see clear cases where a horizontal furnace is not the best value.

- Very cold regions without cheap gas: cold-climate heat pumps or a dual-fuel hybrid can lower lifetime cost versus a gas-fired horizontal furnace.

- Homes with sound hydronic piping or plans for in-floor comfort: a modern condensing boiler with radiant distribution often wins on comfort and operating cost, despite higher upfront spend.

- Attics or crawlspaces with leaky, unsealed ducts: any forced-air furnace will waste energy. It is like heating with the windows open. Seal ducts first or consider ductless heat pumps.

- Existing vertical closet or basement layout: a high-AFUE vertical furnace can be simpler and less costly to install than reworking framing for a horizontal unit.

Alternatives that often pencil out: high-SEER2 or ductless heat pumps in warm or mixed climates with incentives, high-AFUE vertical furnaces, and condensing boilers with radiant.

Common myths to skip: lowest upfront price equals best value, horizontal is always cheaper to run, SEER applies to furnaces, bigger equipment is better, and skipping maintenance preserves efficiency. Neglecting tune-ups can erase expected gains.

Conclusion & recommendation: a quick decision guide and next steps

There is no universal winner. The best choice pairs appropriate efficiency with correct sizing and distribution, your local utility rates and incentives, and a real maintenance plan. Baselines are rising as regulations tighten, with many furnaces trending toward about 95% AFUE by 2028.

We know this can feel complex. Check utility and federal rebates, many favor heat pumps, and plan resilience. Both gas furnaces and heat pumps need electricity for blowers and controls, so consider backup power where outages are common.

- Get 2+ apples to apples bids with Manual J, S and D.

- Compare 10 to 15 year TCO, include rebates and maintenance.

- Require commissioning reports and schedule annual service.

- Seal and insulate ducts to capture 15 to 50 percent savings vs older systems.

Our team has 30+ years in HVAC and U.S.-based phone support. Ready to move forward?

- Get a Custom Quote, wholesale pricing with fast, often free shipping

- Talk to Our Team by phone for sizing and selection

- Shop Heat Pumps or Gas Furnaces, financing with Affirm available