A New Era: What Communicating Side Discharge Heat Pump Systems Bring to HVAC

Communicating side discharge heat pump systems pair a compact outdoor unit that discharges air horizontally with indoor components that share a digital conversation. Instead of simple on and off cycles, an inverter driven compressor and variable speed fans modulate like a dimmer switch, matching capacity and airflow to the real load.

In practice, that delivers steadier temperatures with fewer swings and noticeably quieter operation, a good fit for dense neighborhoods or narrow side yards. Long low speed runs improve seasonal efficiency, and continuous low speed circulation supports better indoor air quality throughout the day.

The communicating controls link everything over a shared bus, so the outdoor unit, air handler, and thermostat adjust in sync. Built in diagnostics monitor sensors and performance in real time, and remote monitoring can provide quick insight when needed. That approach supports reliability and longer equipment life by surfacing issues early rather than after a shutdown. From our field experience, this class of heat pump brings modern comfort, efficiency, and diagnostics in a small footprint that suits many homes where space and sound matter.

What Is a Side Discharge Heat Pump? Form, Fit and Where They Work Best

Communicating side discharge heat pump systems are full heat pump systems that reverse refrigerant flow seasonally to provide cooling and heating. The outdoor unit expels air horizontally from a slim cabinet rather than out the top. That sideways airflow, plus the narrow footprint, reduces overhead clearance and opens up sites that would block a traditional condenser. We place them in tight side yards, patios, balconies, townhomes and dense urban infill. Many models mount on wall brackets or elevated stands to clear snow and landscaping, keeping airflow unobstructed and service friendly where top discharge units will not fit.

What 'Communicating' Means: How Networked Controls Change HVAC Operation

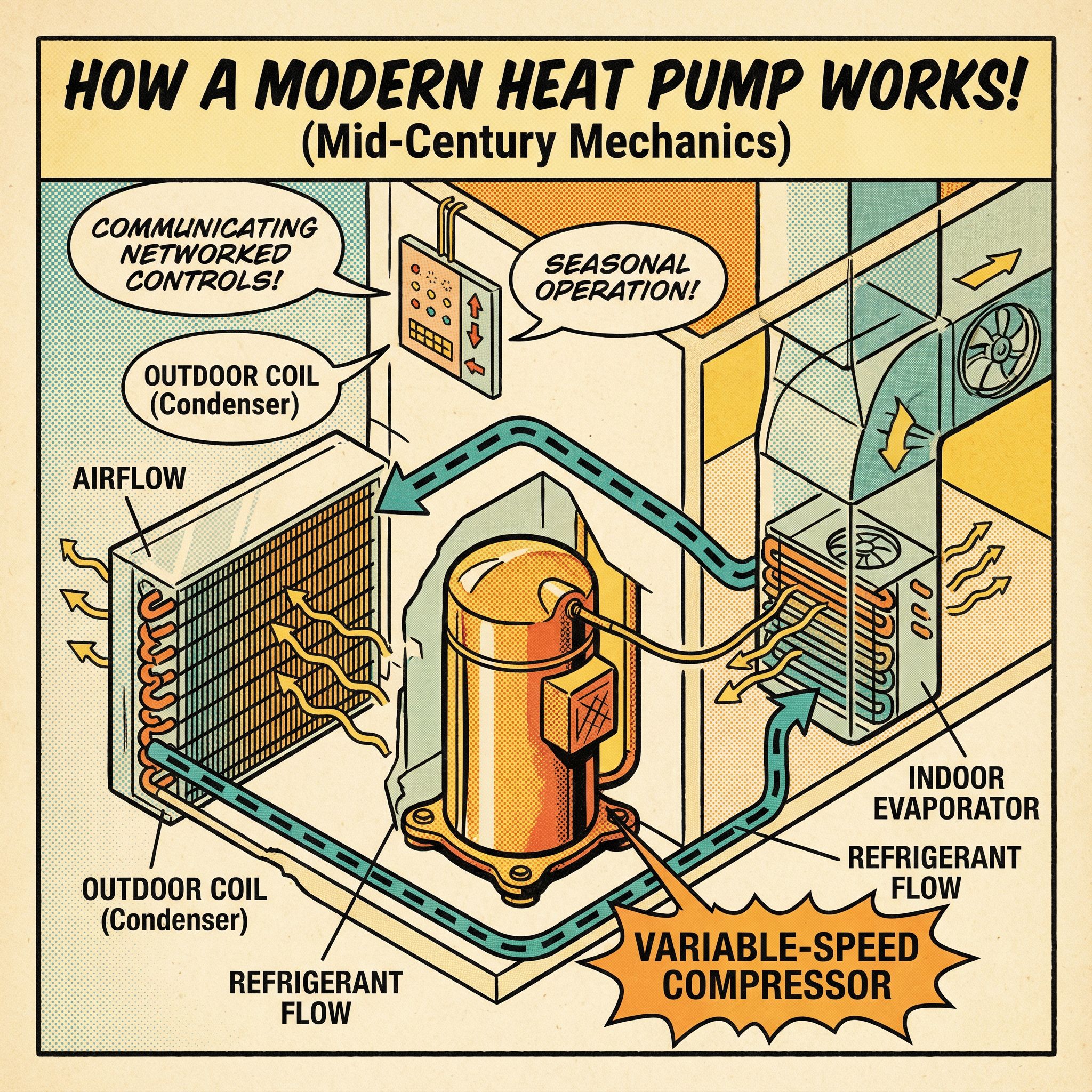

A communicating system links the outdoor unit, the indoor air handler or coil, and the thermostat on a shared digital bus. They exchange sensor and status data in real time, so the compressor and blower modulate together, backup heat stages only when needed, and commissioning steps are guided instead of guessed.

On that digital bus, control and diagnostics are built in: semi-automatic setup, plain-language fault codes, guided tests, and event histories. Connectivity often adds Wi Fi or app access for remote monitoring, usage tracking, firmware updates, and limited third-party automation tie-ins. In the field we see this coordination cut install time, speed troubleshooting, and hold performance closer to design conditions during everyday operation.

How They Work: Inverters, Modulation and the Behavior That Drives Comfort

Modern inverter heat pumps use a variable-speed compressor with matching indoor and outdoor fans. Instead of blasting on and off, the system ramps up or down like a dimmer switch to track the building load. In our experience at Budget Heating (BudgetHeating.com), long low-speed runtimes cut short cycling, smooth room temperatures, reduce drafts, improve dehumidification, and keep gentle circulation for cleaner indoor air.

Communicating controls coordinate compressor and fan speeds, schedule defrost, and set backup heat lockouts, so the heat pump does the work and auxiliary heat only joins when necessary. When selected and sized correctly, today's designs maintain meaningful heat at lower outdoor temperatures than older units, which can trim fossil-fuel use in many climates while staying quiet and steady.

Side Discharge vs Top Discharge and Traditional Systems: Key Tradeoffs

Side discharge paired with inverter variable speed typically runs quieter than many single stage top discharge condensers, so it is a better fit near bedrooms, patios, and close lot lines. Smaller, lighter cabinets and horizontal discharge can ease handling, shorten line set runs, and allow reuse of existing ductwork, which often makes ducted retrofits simpler than replacing with large rooftop units.

Siting matters. Orient the discharge away from neighbors or reflective façades, maintain all manufacturer clearances to prevent recirculation, and review published dB(A) ratings. Confirm HOA or municipal sound rules before placement to avoid issues after installation.

When a Communicating Side Discharge Heat Pump May Not Be the Best Choice

Communicating side discharge heat pumps perform well, but not always. In very cold, design temperature climates, capacity and defrost cycles can limit comfort, so a cold climate heat pump or a high capacity gas furnace may be better. Homes with no ductwork see cost and complexity rise with ducted conversions, whereas ductless mini splits or packaged units often fit better. If the project has a tight budget, a simple single stage replacement can be more practical. Expect higher equipment and installation costs than basic units. Sizing is like shoes, too big makes you stumble and wastes energy.

Plan for backup heat below the balance point, typically electric heat strips or an existing furnace. In our field installs, performance hinges on setup: accurate Manual J/S, matched indoor and outdoor components, clean refrigerant practice with pressure testing and deep vacuum, verified horizontal discharge clearances, defrost condensate management, and full commissioning of the communicating controls. Confirm duct capacity and static pressure, electrical circuits, and smart home or BAS compatibility. Myths to avoid: refrigerant is not consumable, recurring low charge means a leak.

Key Communication Protocols and BMS/IoT Integration: BACnet, Modbus and Beyond

Communicating heat pumps plug into a building like a new app on a phone: they must speak the same language and share the right data. Start by confirming platform compatibility between outdoor unit, air handler and controller. Check available protocols, native or through gateways, for BACnet, Modbus, LonWorks, or MQTT gateways where supported. Verify the points list you can read and write, cloud versus local control options, and privacy/data policies before you specify. Many systems use proprietary links plus Wi-Fi apps, yet tie into BMS via standard protocols or gateways. Integration enables centralized scheduling, demand response, energy management, remote diagnostics, and firmware update workflows that cut service calls and improve whole-building performance. In our experience at Budget Heating (BudgetHeating.com), a five minute protocol and points review saves hours later.

Performance Metrics Explained: SEER2, HSPF2, COP, and Low Ambient Ratings

SEER2 and HSPF2 are the post 2023 benchmarks for seasonal efficiency. SEER2 and EER2 cover cooling, HSPF2 covers heating. Higher numbers mean lower seasonal energy use. The shift from SEER to SEER2 increased the external static pressure used in testing from 0.1 to 0.5 in. w.c., which better reflects real ducted systems. That change produces more realistic results and typically lowers the numeric ratings compared with legacy labels, even when the hardware is the same.

Federal minimums are now expressed in SEER2 and HSPF2 terms. For residential split heat pumps, the floor is commonly 14.3 SEER2 and 7.5 HSPF2, and manufacturers retested and relabeled equipment under the new rules. In our field experience, communicating side discharge models usually land in the mid to high teens for SEER2, while premium inverter offerings reach the low 20s. Under the updated test, HSPF2 often falls around 8 to 10.

Use COP and low ambient data as point checks alongside HSPF2 to understand cold weather behavior. Remember, ratings assume proper conditions: matched equipment, accurate Manual J and S sizing, duct design that keeps static pressure near manufacturer limits, and quality installation with full commissioning. That is when the published numbers are achievable.

Installation, Commissioning, Maintenance and Calculating Cost/ROI

From pre-purchase to long-term care, this checklist keeps projects on track. In our experience, clear specs, clean installs, and verified commissioning are what deliver comfort and efficiency.

- Pre-purchase checks: require a room-by-room Manual J and a Manual S selection. Review matched AHRI certificates, SEER2/HSPF2 ratings, and low-ambient capacity tables. Confirm ductwork, filtration, and total external static pressure are within limits before ordering.

- Quotes and documentation: obtain 2 to 3 detailed quotes listing indoor and outdoor model numbers and controls, scope of work (permits, electrical, ductwork, commissioning), AHRI reference, sound data, and written parts and labor warranty registration steps.

- Incentives: verify federal, state, and utility program requirements, including minimum efficiency levels, AHRI-matched combinations, labels, and any required commissioning reports.

- Electrical and site prep: verify panel capacity, dedicated circuit, and outdoor disconnect per MCA/MOP. Plan line-set routing and length with proper insulation, condensate management, elevation above snowlines, vibration isolation, and service access.

Commissioning best practices: think of it as the test drive and tune before handoff. Insist on pressure testing and nitrogen brazing where required, deep-vacuum evacuation, charging per manufacturer guidance, and airflow verification by measuring total external static pressure and CFM. Verify superheat and subcooling or follow performance charging. Configure communicating controls, including backup heat lockouts and defrost checks, and record readings for the job file and rebate documentation.

Maintenance cadence and safety: homeowners should replace or clean filters every 1 to 3 months, keep outdoor intake and discharge clear, and gently rinse coils annually after power is off. Schedule professional service twice a year for refrigerant verification, airflow and safety checks, firmware updates, and thorough cleaning of coils, blower, and condensate system. Keep written records to preserve warranties. Electrical and refrigerant work belongs to licensed technicians.

Cost and ROI: upfront costs are higher than basic systems, but moving from a code-minimum roughly 14.3 SEER2 unit to about 20 SEER2 can trim cooling electricity 25 to 30 percent. Replacing very old SEER 8 equipment with modern heat pumps can cut seasonal cooling energy by 50 percent or more. Actual savings depend on local rates, climate, building envelope, proper sizing, and installation quality.

Summary and Next Steps: Specifying and Buying Communicating Side Discharge Heat Pumps

Communicating side discharge heat pumps deliver flexible placement, quieter operation, strong SEER2/HSPF2 performance, better comfort and IAQ, and advanced diagnostics through inverter control and system communications. Since payoff depends on design and setup, treat it as a whole system upgrade, confirm climate fit, insist on Manual J/S and AHRI matched selections, verify incentives, and plan maintenance and firmware updates.

- Get a Custom Quote: we include Manual J/S support, AHRI matches, SEER2/HSPF2 compliance, low ambient capacity, warranty terms and commissioning scope so you can compare detailed quotes, plus wholesale pricing with free shipping on most systems and Affirm financing.

- Talk to Our Team: U.S.-based phone support from a factory authorized dealer with 30+ years in HVAC and 200,000+ orders, experienced with inverter and communicating systems.

- Shop Communicating Side Discharge Heat Pumps: compare Goodman, Rheem, Bosch and Gree options ready to ship from our Pennsylvania and Houston warehouses.