If Your Furnace Is Loud, Don't Ignore It: A Quick Safety-First Overview

After decades working on home heating equipment, we treat new or loud furnace noises as diagnostic signals, not background chatter. A sudden bang, rattle, whistle, or squeal can point to airflow restrictions, worn or loose parts, ignition problems, or combustion issues. Left unchecked, these problems reduce comfort, raise energy use, degrade indoor air quality, and shorten equipment life. Think of it like a bicycle chain that starts to rattle, the sound is telling you where to look.

This overview sets a safety-first tone. We outline simple, non-invasive checks you can do confidently to sort minor, DIY-fixable concerns from symptoms that call for a licensed HVAC technician. You will learn what sounds are typical, what noises signal risk, and which quick inspections help you narrow it down without opening panels or touching gas or electrical components. Regular maintenance quiets most systems, improves safety and efficiency, and helps you catch issues before they become expensive repairs.

Safety First: Shut Off Power and Gas Before You Inspect

Before any inspection, cut power. Like swapping a light fixture, start by flipping the breaker or service switch to off, then keep panels closed until the unit is de energized. Clear any combustible items around the furnace, and confirm the intake and exhaust openings are not blocked.

- If you smell gas, see smoke, notice a burning odor, or a carbon monoxide alarm sounds, turn the furnace off, evacuate, and call your gas utility and emergency services from outside.

- If you hear loud banging or metal-on-metal scraping, cut power and stop using the unit. Do not keep restarting it.

Know your limits. The following are not DIY:

- Electrical troubleshooting or repairs.

- Disassembling gas or combustion components.

- Handling refrigerants. Internal mechanical, electrical, and combustion work belongs to licensed technicians.

Common Noisy Furnace Sounds: What Each Noise Usually Means

Use the character of the sound to triage. Focus on when it occurs (startup versus mid run), its rhythm (single bang versus steady), and pitch (low thud versus high squeal). In our experience at Budget Heating (BudgetHeating.com), those clues get you to the likely cause and urgency quickly.

- Banging or booming at startup: Often delayed ignition in the burner or rapid duct expansion and contraction. Treat as urgent. Shut the system off and have it checked to avoid burner or heat exchanger stress.

- Continuous clicking: Repeated clicks usually point to ignition or relay and control issues when the flame is not lighting reliably. Medium to high urgency. Prolonged misfires can damage components.

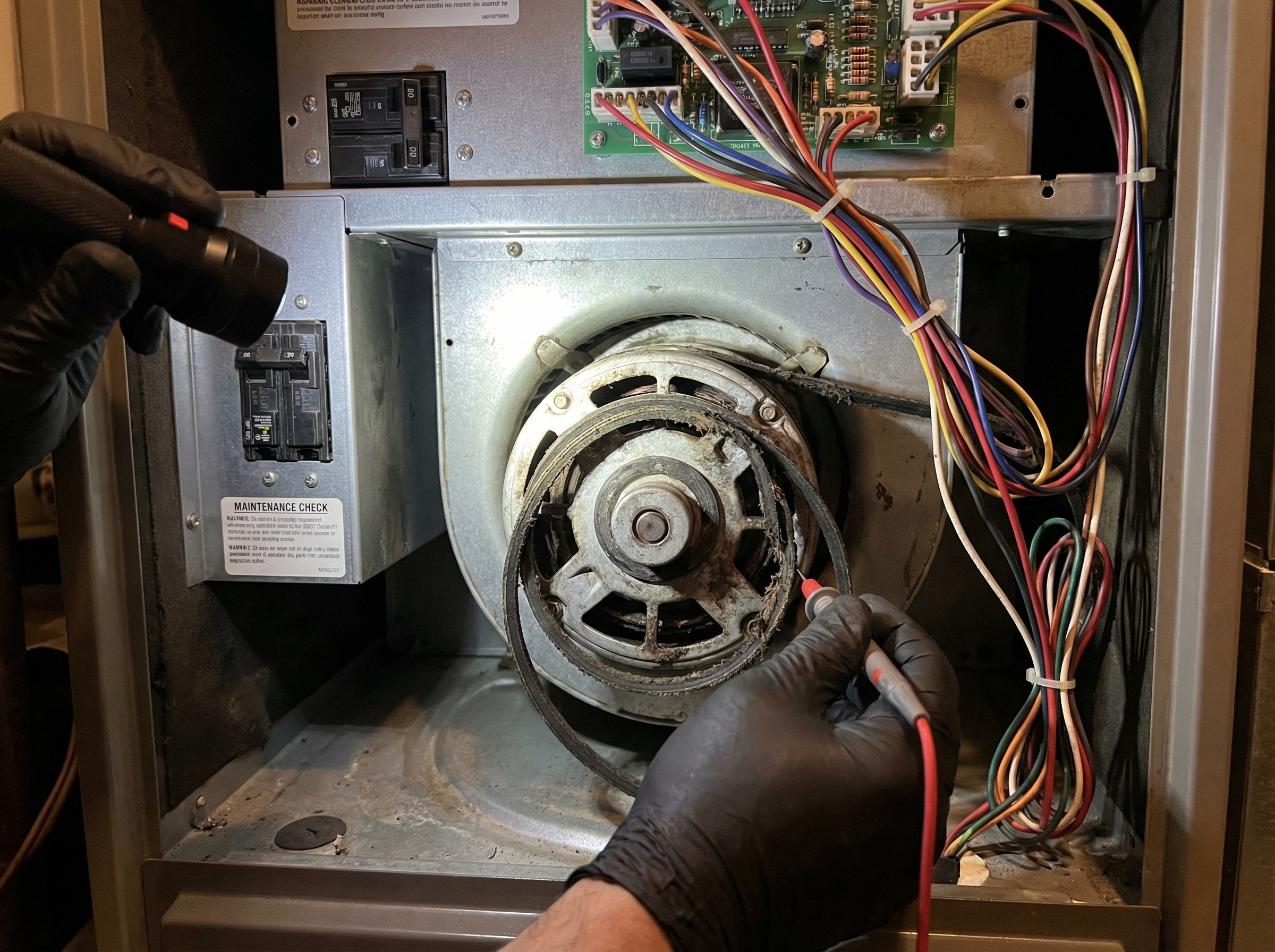

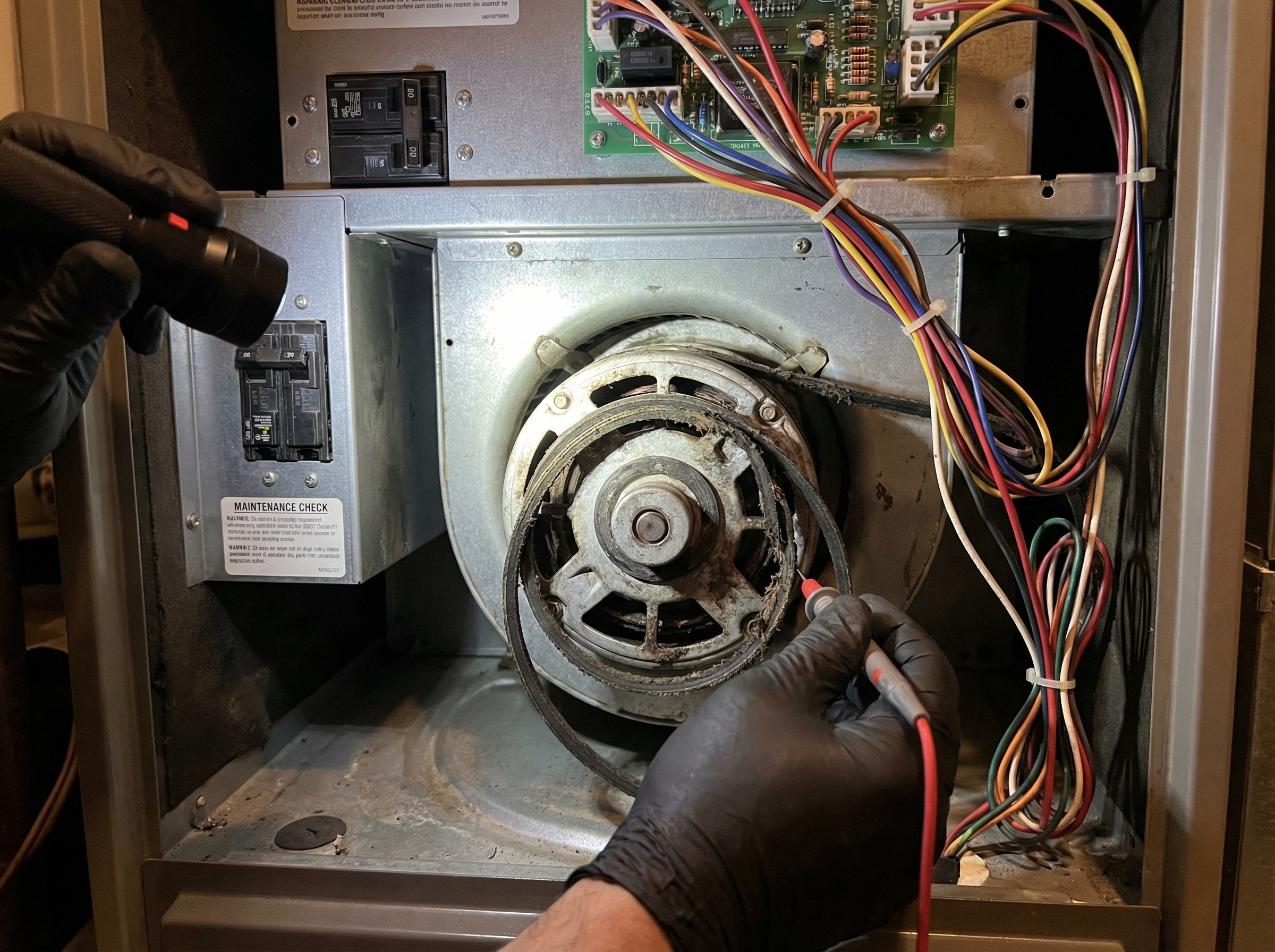

- Grinding or scraping: Typically the blower wheel contacting the housing or failing motor bearings. High urgency. Turn off the furnace to prevent motor or wheel failure.

- High pitched squealing: Commonly a worn blower belt or failing motor or bearing. Schedule service soon. Belts are inexpensive, but bearing failure can cascade into bigger repairs.

- Humming or buzzing: Often from stressed electrical parts like a transformer, capacitor, or relay, or a motor under strain. Address promptly to avoid a no heat event.

- Rattling or light clanking: Usually loose access panels, screws, or duct connections. Low urgency. Tighten hardware and check panel latches.

- Whistling or whooshing: Most often airflow restrictions from a clogged filter, closed registers, or duct leaks. Low to medium urgency. Replace the filter, open supply and return registers, then inspect for leaks.

Quick rule: sharp or metallic sounds and anything tied to startup deserve immediate attention, while gentle rattles or air noise often start with simple DIY checks.

Banging or Booming at Startup: Delayed Ignition and Dirty Burners

A single loud boom at startup typically points to delayed ignition: gas accumulates briefly, then lights all at once, creating a small explosion and a pressure pulse in the combustion chamber or ducts. That pressure wave can sound like a slam. Some homes instead hear banging or popping from sheet-metal ducts rapidly expanding or contracting as they warm. Duct noises are usually less dangerous, though they can be startling.

Treat any ignition-related boom as urgent. Shut the system down and call a licensed HVAC technician for burner and ignition inspection and combustion testing. Until it is inspected, do not continue cycling the furnace. Delayed ignition is a combustion problem, not a nuisance sound, and it can escalate if ignored.

When DIY Isn't Enough: Tradeoffs, Limits, and When to Replace Instead of Repair

DIY has limits. With 30+ years working on heating equipment, we stop DIY when safety or reliability is at stake. If any of the following shows up, end troubleshooting and choose a different path:

- Persistent grinding or scraping

- Loud ignition booms

- Electrical buzzing with burning smells

- Repeated breaker trips

- Suspected heat exchanger cracks

- Ongoing combustion or draft problems

Common mistakes we see: letting a noisy furnace run to see if it goes away, repeatedly restarting after a loud event, assuming clicking or buzzing is harmless, and attempting internal repairs that create safety hazards or void warranties.

Tradeoff analysis: in these cases the right option is a licensed HVAC technician for diagnostics and repairs. If the furnace is old or repairs are frequent, replacement with a modern, properly sized unit may be the better long term choice. A quick fix can postpone risk, it rarely reduces it.

Regulatory and compatibility implications matter. Replacing indoor components can trigger matched system efficiency rules under SEER2 in many U.S. regions, meaning a furnace or coil change can require upgrading the outdoor AC or heat pump to meet SEER2 thresholds. Plan upgrades as a matched system to preserve performance.

Squealing or Screeching? Inspect the Blower Motor, Belts, and Bearings

In our experience, a squeal from the air handler points to the blower package. The usual culprits are a worn or slipping blower belt or failing motor bearings. Both can escalate quickly, and a belt or bearing failure can lead to a seized motor and damage. Treat the noise as urgent, and do not let the unit run repeatedly while it squeals.

Your immediate move: switch the system off. A technician can address belt problems by replacing or realigning the belt and inspecting the bearings. If the sound is due to motor bearing failure, the motor will need professional repair or replacement. Keep the system off until it is evaluated.

Rattling or Vibrating: Tighten Panels, Mounts, and Secure Ductwork

Rattles usually come from loose cabinet panels, a blower door that is not fully seated, loose screws, or unsecured duct joints near the furnace. Loose metal behaves like a drum skin, small gaps vibrate and amplify noise. With power off, tighten accessible screws, reseat the blower door so its safety interlock engages, and move any item touching the cabinet or ducts.

- Quick check: with the system running, keep hands clear of openings and gently press a cabinet corner or duct seam. If the sound changes, that piece is loose.

- If visible ducts flex or oil can, lightly support them temporarily. Then have a professional add fasteners and seal connections with approved hardware and foil HVAC tape, not cloth tape.

- Reduce static pressure to calm duct noise: clean filters and coils, open or balance dampers, and add return air where needed.

Humming or Buzzing: Electrical Components, Capacitors, and Motors Need Attention

Humming or buzzing often points to stressed electrical parts, such as a transformer, capacitor, or relay, or a motor pulling too much current. Diagnostic signs include a steady hum that rises with blower or compressor load, buzzing at startup that lingers, dimming lights, a warm control panel, or a capacitor that looks swollen. Persistent electrical buzzing, especially with a burning smell, smoke, or breaker trips, means shut the system off and get professional diagnostics to prevent fire or bigger failures. In our experience at Budget Heating (BudgetHeating.com), a tech will measure capacitor values, check relays and contactors, read motor current draw, and inspect control circuits to pinpoint the failing part, then make safe, code-compliant repairs.

Step-by-Step DIY Fixes: Change the Filter, Check Belts, Reset Power, and Open Vents

Before diving into anything complex, stick to simple, safe checks that often quiet a noisy furnace.

- Safety first: turn power off at the switch or breaker. Wear safety glasses, work gloves, and hearing protection if you briefly listen during a test run from a safe distance.

- Change the filter: with power off, remove the air filter. If dirty, replace it with the correct size and airflow direction. In heavy-use months, check monthly and replace every 1 to 3 months.

- Thermostat and fan: set the thermostat to Heat and the fan to Auto. Switching from On to Auto can reduce constant blower sound.

- Open airflow: make sure all supply registers and return grilles are open and not blocked by rugs, furniture, or dust. Vacuum the visible grilles.

- Secure what you can: tighten accessible cabinet screws and external duct fasteners. Move boxes or items touching the cabinet or ducts.

- Power cycle and observe: after the steps above, power the furnace off for about 30 seconds, restore power, let a full startup run, and note when and what type of noise remains for a technician.

- Belts: do not open panels to inspect belts. If you suspect belt noise, simply document when it occurs during the cycle.

Act Early: Preventive Maintenance, When to Call a Pro, and Next Steps to Restore Quiet

Safety comes first, and quiet usually follows. Install carbon monoxide detectors near sleeping areas and on every level, test monthly, and maintain them per the manufacturer.

Keep your furnace calm and safe with simple habits: change filters every 1 to 3 months during heavy use, schedule a yearly tune-up with combustion and safety checks, blower and inducer inspection, and a flue or vent inspection, and keep the area clear of combustibles. If your system is older or inherently loud, a properly sized modern furnace with a variable-speed ECM blower and an insulated cabinet can cut noise and deliver 90 to 98 percent AFUE. Matching your cooling side to higher SEER or SEER2 equipment also lowers sound because variable-speed compressors and ECM blowers run more quietly and more steadily. You trade a higher upfront cost for quieter rooms and lower utility bills.

If severe noises persist after simple checks, or you notice grinding, booming at ignition, or electrical burning smells, power the system down and schedule a licensed HVAC inspection right away. If you are deciding what to repair or replace, our U.S.-based team can help you size and select quieter, high-efficiency options by phone.

- Get a Custom Quote for a quiet, high-efficiency system at wholesale pricing

- Talk to Our Team for sizing and brand guidance, real phone support from HVAC pros

- Shop Furnaces, Heat Pumps and AC Systems, free shipping on many items and Affirm financing available