How Much Does a Heat Pump Cost in 2026: What This Guide Covers

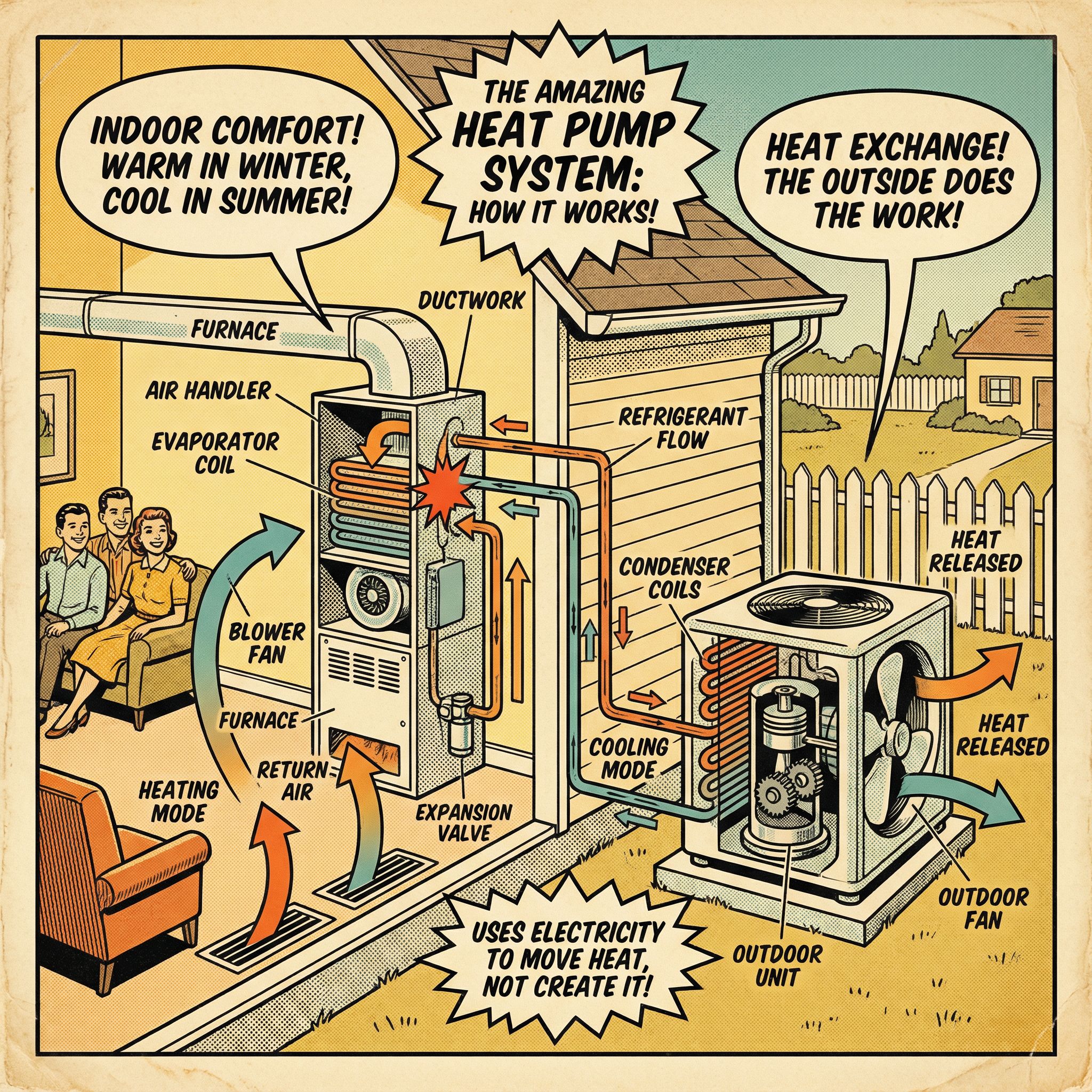

Heat pumps provide both heating and cooling in one system by moving heat rather than creating it. In winter they pull existing heat from outside air or the ground and bring it indoors. In summer they reverse, sending indoor heat outside to keep rooms cool. Think of it like a conveyor belt for heat, not a space heater making new heat. That difference, heat transfer versus heat generation, is the core reason heat pumps can operate efficiently year round.

By 2026, purchase and installation costs vary by home and region, yet they fall within predictable ranges. Drawing on decades of hands-on HVAC experience, this guide sets clear expectations: what drives price, what a typical quote includes, and where savings usually come from. It also explains how to compare bids with equal scope so pricing is meaningful, and how heat transfer efficiency shows up on your energy bill. The goal is to help you understand the full picture before you review numbers.

2026 National Average: Typical Installed Heat Pump Costs (Quick Numbers)

In 2026, typical installed heat pump projects cluster around roughly $6,000. Many homeowners land in the $4,244 to $7,938 range, with a broader reported span from about $1,500 to $12,000. Think of these figures as the sticker price on the lot. The final out-the-door number can shift up or down based on the specifics of your home and system.

Costs vary with system type, home size, ductwork condition, electrical needs, efficiency rating, and local labor. A modest single-stage replacement in a small home tends to sit near the lower end, while larger variable-speed systems or jobs that add ducts, pads, or electrical upgrades push toward the upper end. Regional pricing swings can also reflect permit requirements and seasonality. National averages are a helpful starting point, not a final quote for any particular home.

Cost by System Type: Mini Splits, Standard Central, Premium Central & Geothermal

Comparing system types is easiest when you look at installed price next to bare equipment cost. In our experience, the cost profile depends on how the system covers the home: per room, whole home, or ground loop based.

- Mini split heat pump (single zone): About $1,500-$5,000 installed per zone, with equipment often $1,000-$3,500. Great for one room or a defined zone, and costs scale as you add zones.

- Standard central air source heat pump: Typically $8,000-$15,000 installed for whole home coverage, with equipment often $2,000-$5,500. A single outdoor unit tied to ductwork spreads comfort throughout the house.

- Premium central air source: About $12,000-$20,000 installed, with equipment roughly $6,000-$12,000. Higher efficiency, variable speed, and cold climate features drive the equipment portion up.

- Geothermal heat pump: Commonly $12,000-$25,000 installed for small to medium homes, with equipment often $4,000-$8,000. Large or complex projects can exceed $30,000 due to loop field work.

Each type has a different cost shape. Mini splits are modular, like adding speakers room by room, so totals rise with each added zone. Standard central systems concentrate value in a single whole home install. Premium central systems shift more cost into sophisticated equipment. Geothermal typically carries the highest install component because of the ground loop.

As a quick snapshot: whole home air source systems commonly install for about $8,000-$15,000, premium central models about $12,000-$20,000, ductless mini splits for a single zone about $1,500-$5,000, and geothermal systems about $12,000-$25,000, sometimes higher.

When a Heat Pump May NOT Be the Best Choice: Honest Tradeoffs

We like heat pumps for many homes, but there are situations where another path fits better. From years in the field, here are the honest tradeoffs.

- Very cold climates: Air source heat pumps work best in mild or temperate regions. In deep winter, capacity and efficiency fall as outdoor temperature drops. If you are unwilling to use backup heat, a traditional gas furnace or a dual fuel system is often a better choice. If you stay with a heat pump, select a cold climate model and plan for backup.

- Backup expectations: A heat pump is built to carry most of the load, not every hour of a polar snap. Plan on supplemental heat during those extremes, or choose a furnace or dual fuel setup to avoid comfort dips.

- Whole home from one mini split: Assuming one wall unit will heat a multi room home is a common mistake. Expect uneven rooms. Use the right zoning or a different system layout instead of a single head solution.

- Budgeting missteps: Do not look at equipment price alone. Consider installed cost and available incentives. Skipping that math often leads to a poor outcome.

Equipment vs Installation: What Shows Up on Your Quote

When we price a system, we separate the equipment price from the installed price. Equipment only is the indoor and outdoor units and matched components. Entry to mid tier air source equipment, roughly SEER 14 to 20, typically runs about $1,600 to $9,500 before installation, and the hardware is often the minority of the total project.

The installed price is the out the door total, similar to a car purchase, and bundles all site work and professional services:

- Labor for removal and set, duct transitions or repairs

- Electrical work, panel upgrades, dedicated circuits, disconnects

- Permits and inspections

- Refrigerant handling, evacuation, charging, pressure testing

- Condensate drains or pumps, overflow protection

- Mounting pads, stands, vibration isolation, crane or lift if needed

- Commissioning, airflow balancing, thermostat configuration

What drives cost beyond the box itself:

- Efficiency rating, SEER2 and HSPF2, and variable speed technology

- Brand positioning and available warranties

- Home size and load, number of zones

- Duct condition and accessibility

- Required electrical upgrades

- Site complexity, attic or roof work, line set routing

- Local labor rates and permit fees

Higher SEER or SEER2 models use larger coils, ECM blowers, and variable speed compressors. Those parts increase upfront price, though operating costs typically fall compared to basic single stage options.

How Size (Tonnage & Zones) Affects Your Heat Pump Price

In our experience, system size is the biggest driver of price. As tonnage goes up, equipment cost rises and installation scales with it, since larger outdoor units and matched indoor components take more materials and time. Zones matter the same way. Each indoor zone adds hardware and setup time, so multi-zone jobs cost more than single-zone. With ductless mini-splits, pricing is typically per zone. Once you add several heads, a multi-zone ductless solution can approach central-system pricing. The exact price for any home is driven by system type and size, tonnage and the number of indoor heads or zones. Larger tonnage and multi-zone systems increase both equipment and installation costs proportionally.

How to Get Accurate Quotes: A Homeowner’s Pre Quote Checklist

Use this checklist to help contractors quote the same scope and to ensure the system is sized, installed, and commissioned correctly.

- Prep your home info: define comfort goals and budget, record square footage, insulation quality, and window count, note current HVAC model and issues, check electrical panel space, and look for duct leaks or undersized returns.

- Require proper sizing: ask every bidder for a formal ACCA Manual J load calculation and the matching Manual S equipment selection and Manual D duct design. Confirm the proposed capacity matches the calculated loads. In cold climates, verify heating capacity at your winter design temperature, not just at 47°F.

- Clarify scope and logistics: who pulls permits, which incentives they will help file, exact inclusions and exclusions, warranty terms, and a good, better, best equipment option with timelines.

- Insist on commissioning and documentation: think of commissioning as the test drive and tune of a new car. Require day of startup checks for refrigerant charge, airflow and external static pressure, and thermostat calibration. Request copies of the commissioning report, Manual J/S/D, warranty registration, and a homeowner walkthrough. In our experience at Budget Heating (BudgetHeating.com), this catches issues like low airflow or undercharge on day one.

- Compare apples to apples: collect at least three itemized quotes listing brand and model, tonnage or BTU, SEER2 and HSPF2, included ductwork and electrical, permits, old equipment disposal, and any special gear needed such as a crane or pad.

- Plan for air quality and upkeep: discuss filter MERV rating and static pressure limits, humidity control, fresh air options, the routine maintenance schedule, and who services warranty work.

Regional Differences & 2026 Rules That Affect Price and Selection

Regional climate guides choices, but 2026 federal changes will shape price and selection everywhere. Local codes and incentives can shift cost and timelines.

- Efficiency standards rise in 2026. Many splits near 17 SEER2/12 EER2, packaged near 16 SEER2/11.5 EER2. Expect a modest bump in baseline price with lower operating cost.

- Refrigerants change on Jan 1, 2026. New equipment must use GWP under 700, such as R-32 or R-454B (A2L). This affects availability, training and certification, and can add a small upfront cost.

- Newer central systems are expected to support grid programs; some rebates require compatible controls.

- Local codes and rebates vary. Permit fees, inspections, and code updates can add cost and lead time. Many programs set specific technical and enrollment requirements.

Incentives, Rebates & Federal Tax Credits That Cut Your 2026 Net Cost

In 2026, incentives materially change what you actually pay for a heat pump. The federal income tax credit commonly equals about 30% of the project cost with a $2,000 cap, programs and exact structure vary, and you claim it when you file. In our experience at Budget Heating (BudgetHeating.com), planning incentives up front often shapes equipment choice and timeline. Many utilities and states layer on rebates that favor higher efficiency or cold-climate models. In some areas you can stack incentives, with utility rebates paid at purchase or post-install and the tax credit later, and certain programs even help with panel or wiring work, trimming thousands from the gross cost. It works like stacking coupons at checkout: first the invoice drops, then tax time reduces the remainder.

Is a Heat Pump Worth It in 2026? Final Verdict & Next Steps

Bottom line: for most homes in 2026, a properly selected and installed heat pump is worth it. Typical annual energy savings are roughly 300 to 650 dollars, with favorable cases above 1,000, and your net cost is the installed price minus incentives. Higher efficiency standards and the refrigerant transition may raise baseline equipment prices a bit in 2026, but they improve operating efficiency and environmental performance over the life of the system.

To capture the value, get a formal Manual J load calculation, collect multiple itemized bids, consider replacing heating and cooling together, and pair the new system with basic envelope upgrades and routine maintenance. Done right, the system can deliver rated efficiency for 15 to 25 plus years.

We know this is a major decision for your home and budget. Our team can translate the numbers into the right equipment package and accessories, backed by decades of hands-on HVAC experience and U.S.-based technical support.

- Get a Custom Quote

- Talk to Our Team by phone for quick, no-pressure answers

- Shop Heat Pumps