Mini splits for a 1,000 sq ft home: what they do and why they're worth considering

A ductless mini split pairs a compact outdoor unit with one or more indoor air handlers, connected by refrigerant lines, so there are no duct losses. For a 1,000 sq ft home, that delivers zoned comfort, quieter operation, and steadier temperatures than window units or a tired central system. From years in the field, we see well designed systems lower monthly bills, help offset the upfront cost, reduce dust from old ducts, and improve indoor air quality.

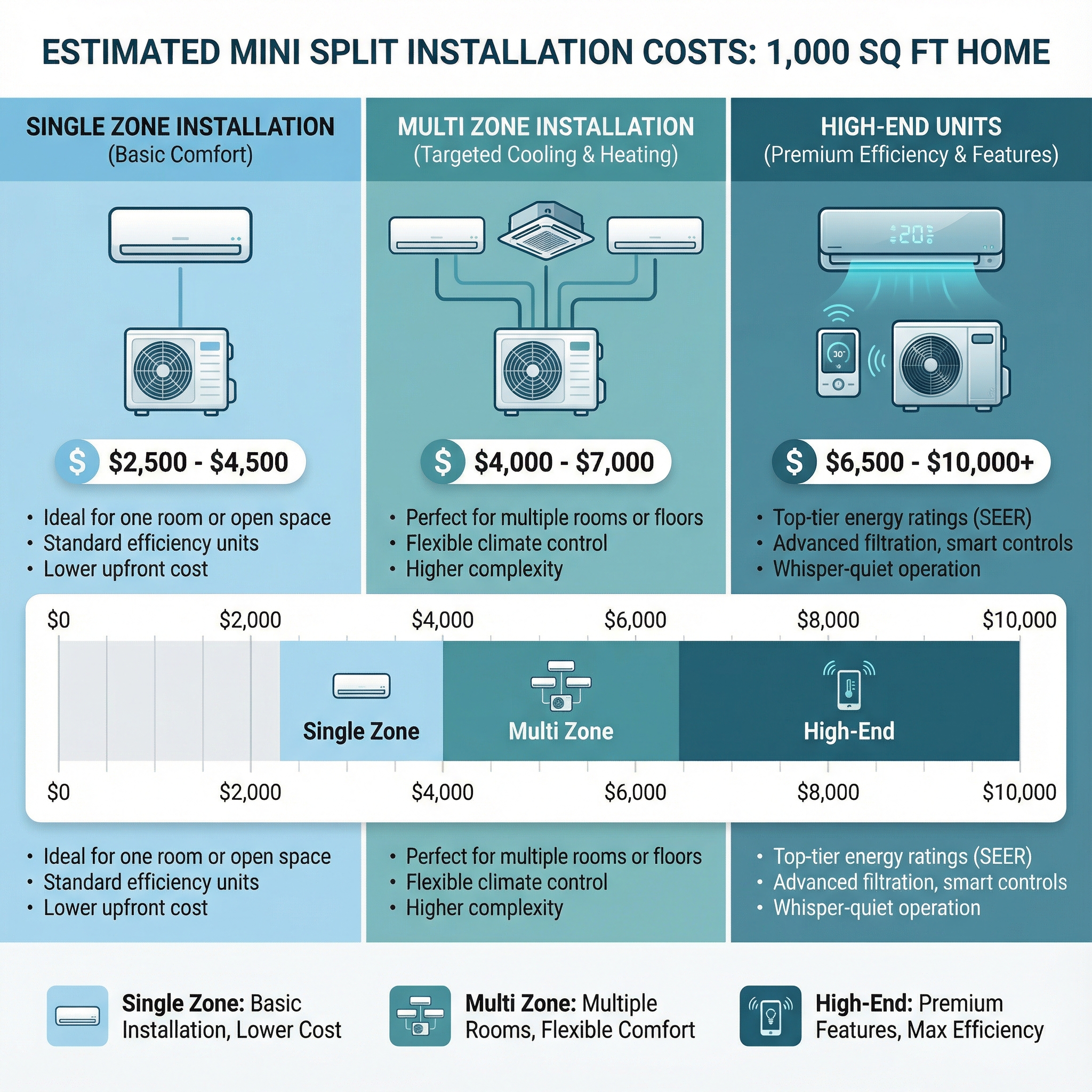

Quick answer: typical installed price ranges for a 1,000 sq ft home

For a 1,000 sq ft home, a complete installed system usually runs $3,000 to $10,000, including equipment and pro labor. We find cost hinges on zones.

- Single zone: equipment is commonly $1,500 to $3,000. Installed totals typically land between $2,500 and $6,000, depending on line set length, mounting, and electrical.

- Multi zone: common projects run about $4,000 to $8,000+. Dual zone often falls $4,500 to $8,000. Three zone jobs frequently come in around $6,500 to $11,000+.

These headline figures generally cover the outdoor unit, the indoor head or heads, standard materials, and typical labor. Choose a single zone when one area needs conditioning. Step to multi zone when two or three distinct rooms need their own heads, which adds refrigerant lines, controls, and labor, and raises the total.

Why costs vary: the main drivers that change your quote

Quotes spread because equipment and labor are tailored to your home. Think of it like a kitchen remodel: finishes and layout steer the total.

In our experience at Budget Heating (BudgetHeating.com), the biggest swings come from a few predictable places:

- Brand and features: quieter operation, smart controls, advanced filtration, and longer warranties raise equipment cost.

- Design choices: zone count, indoor unit types and locations, and whether you use wall mounts, cassettes, or concealed units change both equipment and labor.

- Installation complexity: longer refrigerant line runs, concealed routing with line-hide or soffits, condensate pumps, and tricky outdoor unit locations increase time and materials.

- Electrical and permits: permits, inspection fees, required disconnects, and any dedicated circuit or panel upgrade add to the bill.

- Local market effects: regional labor rates and contractor availability materially influence final price.

Single zone vs multi zone: which setup fits your 1,000 sq ft house (and at what cost)?

Think of zoning like light switches: one switch for the whole space versus a switch in every room. For a 1,000 sq ft home, layout drives the choice. Single zone works best in studio or open floor plans where one indoor head can wash the main area, and it is typically the least expensive. The tradeoff is comfort in closed bedrooms or offices, which can run warmer or cooler with doors shut. Multi zone systems with 2 to 4 indoor heads suit homes with separate rooms, giving each space its own setpoint, at higher equipment and installation cost.

From field experience, multiple smaller single zone systems can sometimes beat one oversized multi zone on both price and performance, because each head modulates to its room and installs are simpler. Whatever you pick should align with the load you already calculated.

- If existing ductwork is in good shape, a small ducted heat pump can deliver whole home comfort efficiently.

- If you have many small closed rooms, a ducted mini split air handler with short runs can balance temperatures better.

- For short term spaces, a window or through the wall unit may be the lowest upfront cost.

Electrical work, permits, line sets and outdoor placement that add to the bill

Many mini splits need a dedicated 208/230 V circuit with a correctly sized breaker, a disconnect, proper wire gauge and grounding. Think of that circuit like a reserved parking spot. If the panel is full, a panel upgrade may be needed.

- Line sets and finishes: shorter runs cost less. Add per foot tubing, wall penetration, line hide or soffit, and a condensate pump when gravity drain is not possible.

- Outdoor placement: maintain clearances, ensure drainage, add snow or ice protection in cold zones, and manage noise. HOA or city setback rules can change location and cost.

- Permits and inspections: fees vary by locality and are often bundled in quotes, but confirm what is included.

System size & BTU: how big a mini split does a 1,000 sq ft home actually need?

Square foot charts are a blunt tool. Proper sizing comes from a Manual J load calculation, which models your home's unique heat loss and gain. That means factoring climate zone, orientation, insulation and air sealing levels, window area and shading, infiltration, occupancy and appliances, and any duct or ventilation losses. Think of it like shoe sizing for your house. Being close is not enough. The fit must be right.

For a 1,000 sq ft home, many U.S. scenarios land around 18,000 to 24,000 BTU of total capacity. If the envelope is leaky, insulation is thin, or winters are severe, needs can climb, often up to roughly 36,000 BTU. Layout matters too. An open plan can be served by one head more easily than a chopped up floor plan that needs multiple zones.

Undersized systems run constantly, struggle in extreme weather, and may never hit the setpoint. Oversized systems short cycle, creating temperature swings, poor humidity control, extra wear, and lower seasonal efficiency. Even with inverter equipment, too much capacity still wastes energy and reduces comfort. Manual J prevents both mistakes.

Equipment, SEER2 & HSPF2: how efficiency and brand affect price and operating cost

SEER2 and HSPF2 are the current efficiency scores for cooling and heating, think MPG for comfort. SEER2 replaces older SEER with updated test conditions, so quotes now use these metrics. Federal 2026 minimums are SEER 16 in the North and SEER 17 in the South and Southwest. For roughly 1,000 sq ft, many mini splits sit around 17 to 20.5 SEER2, with premium models higher. In our experience at Budget Heating (BudgetHeating.com), higher efficiency and cold-climate series cost more upfront but can pay back quickly: replacing SEER 10 equipment with SEER 14, 18, or 22 can cut annual cooling costs by about $450, $750, or $975, climate and run time depending. Incentives help: the federal 25C credit offers up to $2,000 on qualifying heat-pump mini splits, plus many utilities add $200 to $1,000.

Installation complexity, safety and what professional installers must do

Installing and commissioning HVAC equipment is not a DIY project. Licensed technicians mount indoor and outdoor units, core wall penetrations, braze or flare refrigerant lines, pressure test with nitrogen, purge while brazing, pull a deep vacuum verified with a micron gauge, make electrical terminations, and recover or add refrigerant as required. Commissioning is the preflight check for HVAC: verify charge, airflow, controls, and document readings.

- Pro-only tasks: mounting, coring, brazing or flaring, pressure testing, deep vacuuming, refrigerant charging and recovery, electrical terminations.

- Commissioning checklist: nitrogen purge, tightness test, deep vacuum, leak check, charge verification by superheat or subcooling, thermostat and safety controls.

- Homeowner-safe care: replace or clean filters, keep outdoor coils clear, gently rinse coils with power off, monitor condensate drains.

- Safety musts: do not cut refrigerant lines, do not work on live panels, use basic PPE, maintain carbon monoxide detectors near combustion appliances.

Cost breakdown, operating costs and real world quote examples for a 1,000 sq ft home

We typically see: single zone open layout $2,500-$6,000 installed; multi zone for several rooms $4,000-$8,000; premium three zone $6,500-$11,000+.

Installed cost covers: outdoor unit and indoor heads, line sets, pad or wall bracket, condensate drain or pump, electrical work, permits, and start up/commissioning labor.

Higher SEER raises upfront price but trims annual kWh, and rebates plus the federal tax credit can reduce net cost. Budget pitfalls: sizing only by square footage, treating the online equipment price as the whole job, expecting one head to condition closed rooms, and skipping commissioning or electrical checks.

How to budget, get accurate quotes, and take the next steps

Plan your budget first: for a 1,000 sq ft home, installed costs typically land around $3,000 to $10,000. If funds are tight, phase the project by tackling high use areas first. Check federal 25C credits and local rebates before locking in equipment. Decide on cooling only or a year round heat pump, request a Manual J, and compare multiple itemized quotes that include equipment, line set length, electrical work, permits, and commissioning. Keep filters and coils clean, and schedule professional commissioning and periodic checks to protect efficiency and warranties.

- Have contractors specify: outdoor unit model and efficiency, indoor head types and locations

- Confirm included line set length plus per foot adders

- Verify condensate handling, electrical scope, permits, and commissioning steps

The big takeaway: clear goals and apples to apples quotes reduce surprises and net your best price after incentives. We know this is a meaningful investment. Our factory authorized team, with 30+ years and 200,000+ orders fulfilled, can spec the right system at wholesale pricing.

- Get a Custom Quote

- Talk to Our Team, U.S.-based phone support from real HVAC pros

- Shop Ductless Mini Splits, many systems ship free and financing with Affirm is available