How modern gas furnaces have gotten noticeably quieter

Modern gas furnaces have moved from the loud whoosh and rattle many people grew up with to a much calmer presence in the home. That shift is intentional. Today's units are engineered for quieter start-up, steadier operation, and reduced vibration through coordinated improvements in three areas: combustion, airflow, and cabinet design.

Smoother combustion means the burner lights cleanly and evenly, so you do not get that abrupt flare that used to echo through the basement. Controlled airflow keeps the sound level consistent, avoiding the blasts of air that once made vents whistle and doors flutter. Cabinet engineering does the rest, with tighter panels and strategic internal bracing that tame vibration before it turns into noise. The end result is more of a gentle hum, like a refrigerator at idle, rather than a clatter.

Quieter matters in real life. Conversations stay clear, bedrooms near returns are easier to sleep in, and there is less rattling that can travel through ductwork. There is also a safety benefit. A calm light-off and steady airflow make unusual sounds stand out, so homeowners notice if something changes and can address it before a minor issue grows.

Why furnace noise matters: comfort, sleep, and perceived quality

Furnace sound is not just a nuisance, it shapes how a home feels. Quieter systems run long low-speed heating cycles with smoother airflow, which tames hot and cold swings and cuts drafts, so rooms feel even and calm. Think of a ceiling fan on low, you hardly notice it, yet the room stays consistent.

Lower background noise helps the brain relax. In bedrooms and home offices, a quiet furnace supports deeper sleep, clearer calls, and less stress for noise sensitive family members. The absence of start and stop blasts lets people converse, watch TV, or focus without turning up the volume or concentration.

Silence also signals build quality. Tight cabinets, balanced blowers, and lined panels tend to sound refined, and that refined sound translates to a higher quality experience every day.

Common sources of noise in older gas furnaces (and what you're hearing)

Older gas furnaces tend to be chatty, and the sounds usually point to three root causes:

- Airflow and register noise: Turbulence from smaller heat exchangers, higher fan RPMs, and restrictive ducts creates the familiar air rush or a whistle at registers. It is like forcing a lot of air through a straw.

- On and off cycling noise: Single-stage burners run at full output, then shut off, so the sound jumps abruptly instead of settling into the steadier tone you get with continuous low-speed operation.

- Startup whoosh and rattle: Older single-stage, PSC-motor furnaces often deliver a sharp ignition whoosh and cabinet rattle because the inducer and blower come on abruptly with limited control.

Identify which of these you hear, and you can usually trace the source before chasing fixes.

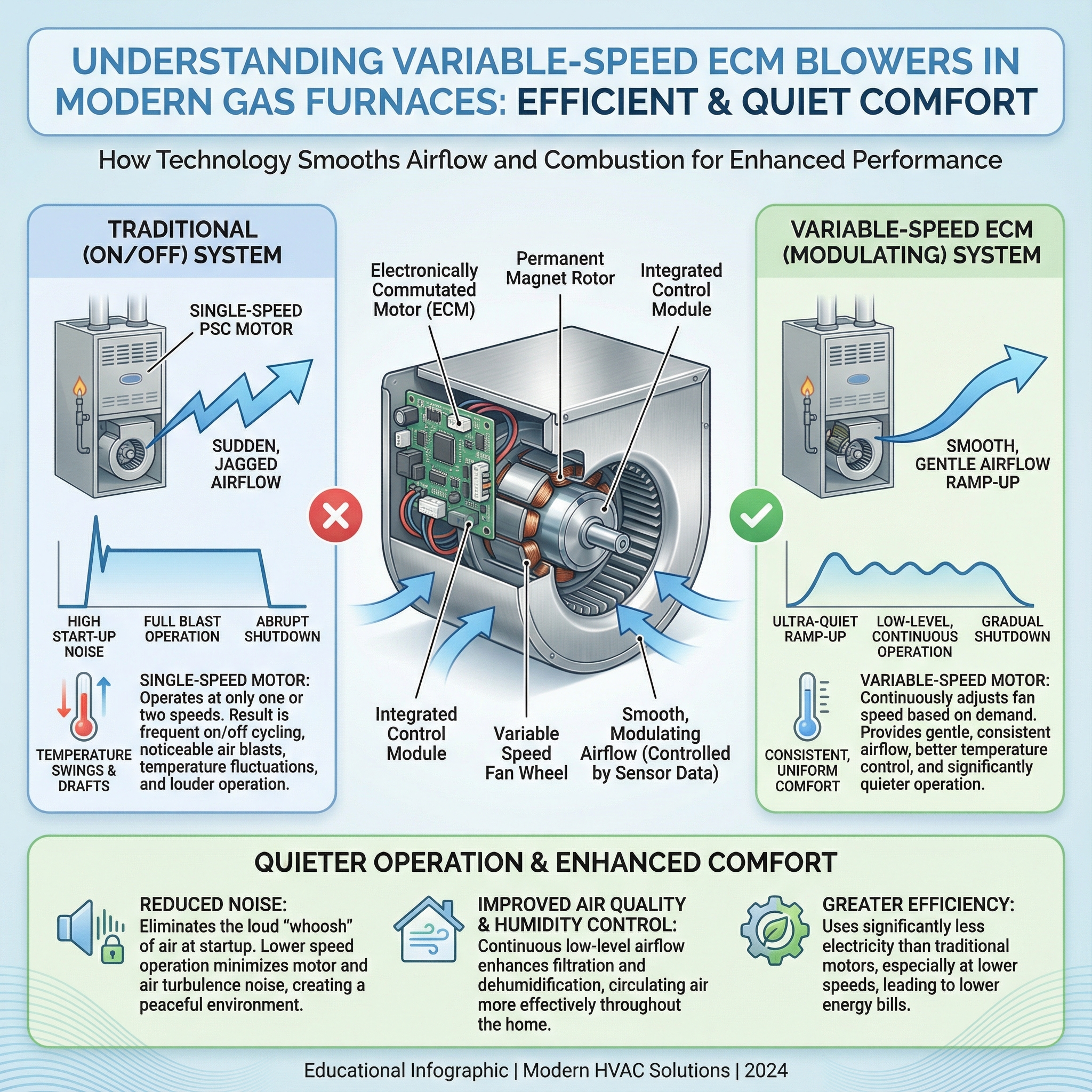

Variable speed blowers: smoother airflow, lower noise, better comfort

From our installs and test benches, the upgrade that most reliably lowers fan and duct noise is a variable speed ECM blower. It behaves like a light dimmer, not a flip switch: starts and stops are gentle, airflow stays smooth, and the rumble from vents drops throughout the day. In typical homes this is the change you notice first, quieter returns and registers without sacrificing airflow. The DOE Furnace Fan efficiency rule accelerated the move to high efficiency ECM blowers, which cut wasted watts and usually sound quieter than older PSC motors.

There is a cooling bonus. The same indoor variable speed blower that quiets heating also improves part load cooling when paired with modern high SEER or SEER2 air conditioners: longer low speed cycles, steadier room temperatures, and better moisture control, which supports higher seasonal efficiency and more even comfort across the home.

When quieter equipment or replacement may NOT be the best choice (tradeoffs and misconceptions)

A quieter, high efficiency gas furnace is not always the smartest upgrade. Consider these cases where other moves deliver more value or fewer headaches:

- Mild climates or low heating hours: the payback can be long. A heat pump or dual fuel setup can be a better fit.

- Poor or undersized ductwork: swapping the furnace alone rarely fixes noise or comfort. Improve duct sizing, layout, and add sound damping first.

- Very old structures with venting or combustion air limits: a condensing unit may need costly alterations. A non condensing model or alternative heat can be simpler.

Common misconceptions to avoid:

- Modern furnaces are not all loud.

- Quieter does not mean weaker, many quiet features also boost efficiency.

- Bigger is not better, oversizing causes short cycling and more noise.

- Quiet gear still needs regular maintenance.

- Replacement is not the only path, targeted fixes often solve the issue.

Key technologies that reduce furnace noise today

Today's quiet furnaces lean on smarter airflow, gentler firing, and better isolation. In our experience at Budget Heating (BudgetHeating.com), the biggest gains come from motor control, burner staging, sealed venting, and cabinet design.

- Motors: Variable-speed ECM blowers ramp softly instead of snapping to full speed. They trim rpm to duct pressure, lowering turbulence and the vibration that can telegraph through framing.

- Burner staging: Two-stage or fully modulating gas valves stay at low fire most of the day, like a light on a dimmer. That reduces burner hiss, allows slower blower speeds, and smooths room temperatures.

- Venting: Modern induced-draft fans, often variable speed, and sealed direct-vent combustion use two pipes for intake and exhaust. This isolates burner noise from living spaces and moves air more smoothly than natural draft. Improved inducer and blower aerodynamics and airflow paths further cut start-up harshness.

- Cabinetry: Quieter cabinets use insulation, tighter panels, and rubber isolation mounts. Look for manufacturer sound-package options and published sound ratings when comparing models.

Improved cabinet design, vibration isolation, and quieter components

Noise falls when the cabinet contains sound and the moving parts slow down. Tightly sealed, insulated cabinets keep fan hiss and motor whine inside, and secured access panels eliminate the little rattles that can telegraph through a home. Soft-mounting blowers and motors on isolation pads, along with correctly tightened fasteners, breaks the path structure-borne vibration uses to reach floors, ducts, and framing. Larger heat exchangers and slower-turning blowers move the same air at lower RPM, cutting blade noise and reducing turbulence in the airstream, like a wider river that runs quieter. Together, these upgrades target both airborne cabinet noise and the vibration that would otherwise spread into the building.

Condensing and high efficiency furnace designs (AFUE, SEER2 and regulatory drivers)

AFUE rates how much of your gas becomes heat over a season. Going from about 80 percent to 95 percent or higher typically trims winter gas use by 15 to 20 percent. The gain comes from condensing heat exchangers and sealed combustion that capture more heat and soften draft noise. In our experience at Budget Heating (BudgetHeating.com), pairing these furnaces with variable speed blowers keeps sound low by running at gentle, lower airflow.

Expect higher upfront cost than a basic single stage furnace, with lower lifetime fuel spend. Federal policy is speeding the change: the DOE amended standard will require around 95 percent AFUE for many homes starting in 2028, pushing condensing, sealed designs and quieter operation. SEER and SEER2 describe cooling efficiency, and the same variable speed equipment that lifts SEER2 also smooths airflow through the furnace, improving overall system efficiency and sound in both heating and cooling. National policy projects large consumer savings over decades.

Installation, commissioning, and maintenance practices that keep furnaces quiet

In our installs, quiet starts with sizing. We run a Manual J, check ducts. Oversized furnaces short cycle, louder on and off. Undersized or restrictive ducts whistle and whoosh. During set, we place cabinets on isolation pads on wood or platform floors, snug panels, soft mount the blower to cut structure borne noise. Commissioning focuses on sealed combustion and safety controls: verify tight vent and intake, correct gas pressure, inducer draft and pressure switch operation, flame signal and limit switch response. That stabilizes burner tone and prevents rumble. Maintenance keeps it that way: annual inspection of burners, heat exchanger, inducer, and blower, plus filter changes and cleaning, keeps airflow smooth and controls reliable. Homeowners should listen for new rattles, squeals, or booms, then fix causes early, like loose fasteners, dirty blower wheels, or failing bearings.

Balancing quiet, efficiency, and cost: what homeowners should do next

Modern furnaces are noticeably quieter because smarter combustion control, variable speed airflow, tighter cabinets, and better installation practices work together to tame startup noise, vibration, and ongoing fan sounds, delivering quieter comfort, better safety, and higher efficiency.

If you are weighing replacement or upgrades, balance quiet, efficiency, and budget by using a simple checklist: confirm goals, quiet plus at least 95 percent AFUE; request features, variable speed ECM, two stage or modulating gas valve, sealed combustion, insulated cabinet; require proper sizing and a duct assessment; verify mounting, isolation, and commissioning details; schedule annual maintenance; consider targeted duct or sound damping improvements before a full replacement.

Our team helps homeowners make these tradeoffs every day, pairing the right features to the budget and the home. When you are ready, we can size the system, review your ductwork, and quote options that hit your noise and efficiency targets.

- Get a Custom Quote

- Talk to Our Team by phone for fast, U.S. based support

- Shop Furnaces