Furnace Running But Not Blowing Air: What That Really Means

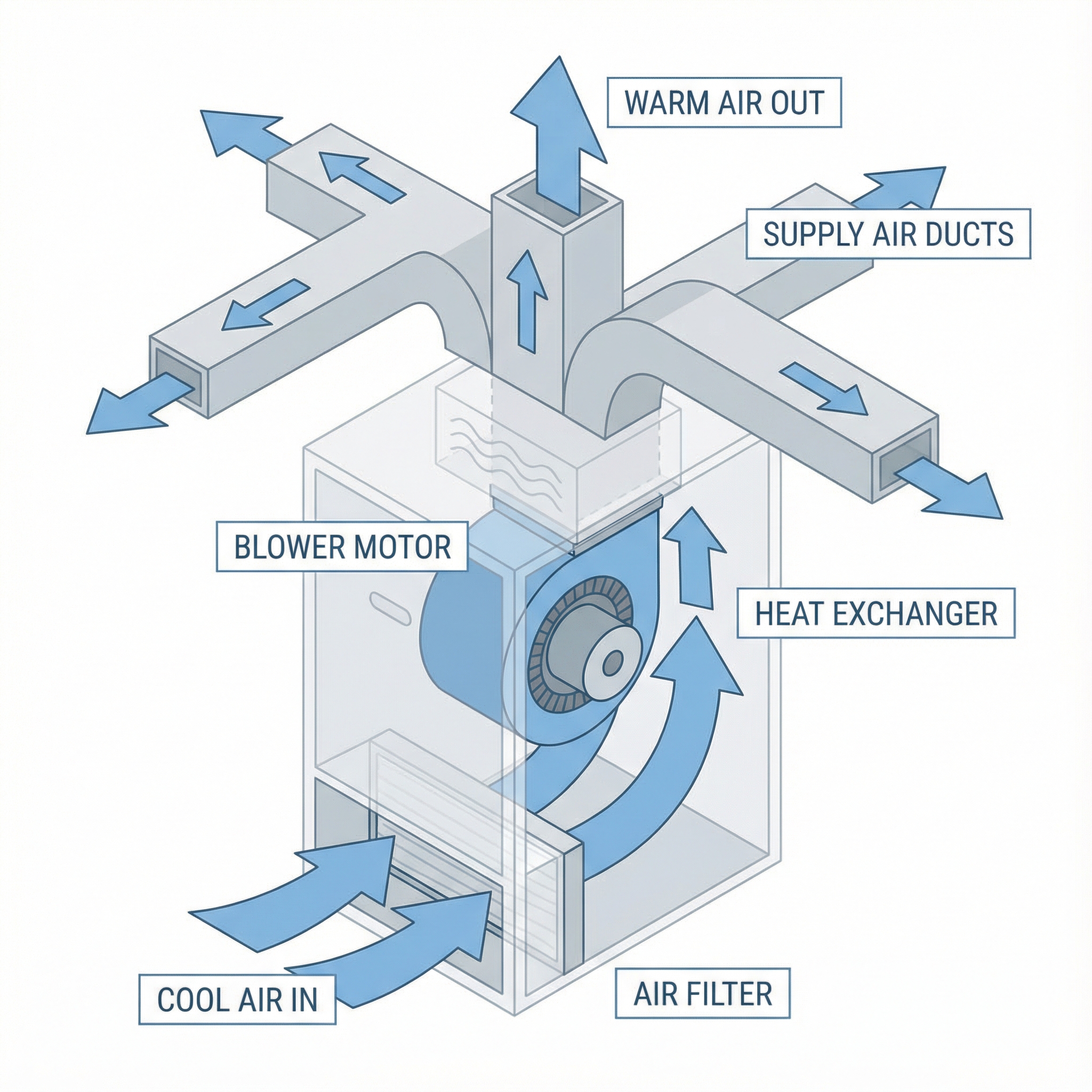

Seeing a flame or hearing ignition while no air comes from the vents usually signals an airflow or blower-side issue, not a total furnace failure. Heat is being made inside the heat exchanger, but the blower is not moving that heat into the ductwork. Think of a campfire without a breeze: the heat stays put instead of spreading through the space. Some furnaces intentionally delay the blower for 30 to 90 seconds after ignition, but if minutes pass with no airflow, something is wrong.

Start with simple, safe checks that often restore airflow without a service call: confirm the filter is clean, open supply and return vents, set the thermostat fan to Auto or On, and make sure the furnace switch and breaker are on. If a panel was recently removed, reseat it so the blower door safety switch is engaged.

Restoring proper airflow quickly improves comfort and protects heat exchangers and motors from overheating or damage. Fixing the air side promptly prevents short cycling, nuisance limit trips, and premature wear, which keeps the system stable while you decide if any deeper diagnostics are needed.

Quick Overview: Common Causes When the Furnace Runs but No Air Blows

If the furnace hums or fires but no air comes from the registers, start with these likely culprits:

- Thermostat fan set to Auto instead of On

- Dirty or clogged air filter

- Blocked supply or return vents

- Failed blower motor or run capacitor

- Faulty blower relay or control board

- Open blower door safety switch

- High-limit or other safety switch tripped by overheating

The blower is the fan that pushes heated air through the ducts. If the motor, capacitor, relay, control board, or door switch is compromised, the furnace can heat but no airflow reaches the vents. Overheating can also trip safeties and interrupt normal blower operation.

Safety First: What to Do (and Not Do) Before You Touch Anything

We always start by turning off power at the breaker before opening any cabinet or removing panels. Treat parts as live until you confirm power is off. Never bypass door interlocks or safety switches. They are there to protect you from shock, shorts, and unexpected starts.

If you smell gas, stop. Do not attempt repairs, light flames, or flip switches. If safe, ventilate by opening doors or windows, evacuate everyone, and call your gas utility or emergency services from outside.

Motors and controls can be hot, so wait for cooling before you touch anything. Some blower motors have a reset button, but press it only once after cooldown. If it trips again, do not restart the overheated motor. Repeated resets can damage windings and point to a deeper fault that needs proper diagnosis.

Filter & Vents: The Most Common and Fastest Fixes

When heat drops off quickly, filters and vents are the first place to look. Airflow is your system's lifeblood, like breath for lungs, and small blockages create big problems. In our experience at Budget Heating (BudgetHeating.com), a dirty filter or closed register causes a large share of no-heat or weak-air calls.

- Replace or clean the air filter: Slide it out and hold it to a light. If you cannot see light, it is clogged. Install the correct size with the airflow arrow pointing toward the furnace.

- Inspect and clean registers: Vacuum supply and return grilles, remove dust and debris, and make sure manual dampers are set fully open.

- Keep vents unobstructed: Move furniture, rugs, and drapes away. Closed or blocked vents restrict airflow and can mimic blower failure.

- Avoid common mistakes: Do not ignore the filter, do not assume the furnace is powered just because you hear internal sounds, and do not close registers to push heat. That tactic backfires and strains the system.

After these steps, feel multiple rooms. Stronger, even airflow usually means you found the fix.

When the Furnace Runs but Only Blows Warm or Weak Air: Tradeoffs and When Not to DIY

Weak airflow is not one-size-fits-all. In hot and humid regions, low airflow can ice the indoor coil during cooling season, and the same restrictions show up in winter as weak heat. In dusty or arid areas, filters load faster and starve the blower. At high altitude, combustion and fan settings often need derating or professional tuning to stay safe and efficient. In our field experience, closing supply vents does not push more heat, it raises static pressure and reduces flow. Hearing clicks or flame does not prove the blower is moving air.

- Gas or ignition issues, safety and code risks.

- Control boards, wiring, or ECM programming, complex diagnostics.

- Refrigerant leaks or charge checks, requires EPA-certified service.

- Airflow matching to Manual J and SEER2 specs on new or modified systems.

Better alternatives include licensed HVAC service for combustion and controls, EPA-certified technicians for refrigerant work, and professional sizing and commissioning to verify airflow and static pressure.

Quick Checks You Can Do Now: Thermostat, Fan Setting and Power

Start with the simplest, reversible checks. In our experience at Budget Heating (BudgetHeating.com), these fix many no-blower calls in minutes.

- Thermostat fan mode: Switch fan to On, not Auto. Auto runs the blower only during a heating or cooling call. On should make it run continuously, proving the motor has power and responds.

- Access panel: Confirm the furnace or air handler door is fully seated and latched. Many units kill blower power if the panel safety switch is open.

- Power to the unit: Check the HVAC breaker or fuse at the panel, then the service switch at the unit. Reset a tripped breaker once. If it trips again, stop and call a pro.

If the fan runs in On but not in Auto, focus on thermostat settings or controls rather than a failed blower.

Inspecting the Blower Motor, Capacitor and Relay: When to Look Inside

When the furnace fires but air never moves, we look for blower-side clues. Listen at the cabinet: a steady hum suggests the motor is trying to start, a rattle or buzz points to a struggling start circuit, and a motor that feels very hot is a red flag. After the system cools and power is off, some blower motors have a small reset button that may bring it back briefly, like a runner needing a quick push off the blocks.

Stop there. Motors, capacitors, relays and control boards store energy and sit on live circuits. Diagnosing or replacing them risks shock, arc and injury. Do not attempt these repairs yourself. Call a licensed HVAC technician for any internal electrical work.

Limit Switches, Control Boards and Wiring: Hidden Failures That Stop Airflow

In many no-airflow calls we see, the safety and control chain is the culprit. The high limit switch, blower relay, and the control board monitor temperature and timing. If a limit opens or a relay sticks, the board can lock out the blower while the burners still fire, so heat builds with no air movement. Wiring that is loose, shorted, or mislanded can mimic the failure, with no obvious external clues.

The board decides when the blower starts, how fast it runs, and when it coasts down. That timing affects cooling efficiency ratings as well as furnace operation. SEER depends on correct airflow from the indoor blower, and AFUE reflects combustion-side efficiency. Restore proper airflow and matched control logic, and a paired AC or heat pump can achieve its rated SEER again.

When replacing a blower motor, relay, or control board, confirm SEER2-era airflow requirements and local standards such as ACCA Manual J, S, and D and the IECC. Manufacturers have revised matched components since 2023, so compatibility matters.

Costs, Parts and Time: What Repairs and Maintenance Typically Run

Based on what we see, a typical furnace repair visit runs about $250 to $300. When major components are involved, totals commonly fall in the $1,000 to $3,000 range. Simple fixes use basic service parts and a short visit, while bigger jobs can take longer if parts must be sourced.

Preventive habits cut surprises: keep the area around the furnace clear, change filters on schedule, clean vents and registers, and schedule annual tune ups. We see about 40% fewer service calls with steady maintenance, and the risk of serious breakdowns drops as industry estimates suggest.

If Quick Fixes Don't Work: Turn Off Power and Call a Licensed HVAC Pro (24/7 Options)

If quick checks did not restore airflow, turn off power to the unit and call a licensed HVAC technician. Many offer 24/7 emergency service. A printable homeowner checklist is not included here. Use the step-by-step checks in this article and contact a pro if you are unsure or the unit still will not move air. With 30+ years in HVAC, our team can size parts or systems and guide you, backed by factory warranties, wholesale pricing, and U.S.-based phone support.

- Get a Custom Quote

- Talk to Our Team by phone or chat today

- Shop Air Handlers & Blowers

- Financing with Affirm and free shipping on most orders