How Often Should a Home Replace Its HVAC System: Why Timing Matters

The typical replacement window depends on the component. Many homes see central AC last about 10 to 15 years and furnaces 15 to 20, with systems overall around 10 to 20. Age is only part of the decision. In 30 plus years of HVAC work, we find performance, repair history, and efficiency matter more than a birthday. Swapping very old equipment can trim electric bills by roughly 20 to 40 percent, depending on climate and usage, and may unlock rebates.

Consider replacement when you notice:

- Frequent or costly repairs in consecutive seasons, or parts becoming obsolete.

- Energy bills trending up, especially with steady thermostat settings.

- Comfort problems: uneven rooms, poor humidity control, longer run times, or excessive noise.

- System uses R-22 refrigerant or has a cracked heat exchanger, both red flags.

Time upgrades for mild weather before peak season, so you can compare options without urgency. That protects comfort and budget.

Typical Lifespan by System Type: When to Start Planning Replacement

In our field experience, most comfort systems follow predictable service windows. Planning upgrades before those windows close avoids midseason surprises and lets you budget on your terms. Use these ranges to benchmark your equipment and decide when to start evaluating options.

- Central air conditioners and heat pumps: typically 10 to 15 years. Start weighing replacement as you approach years 10 to 12.

- Gas furnaces: about 15 to 20 years. Begin planning around year 15, especially if efficiency or comfort has drifted.

- Boilers and other hydronic systems: often 15 to 30 years. Consider options once you are into the late teens, earlier if major repairs loom.

- Ductless mini splits: roughly 12 to 20 years. Start evaluating around years 12 to 15.

Individual components do not age equally. We routinely see ductwork, controls, and certain heat exchange components outlast or lag the main unit. Lifespans across components span roughly 10 to 50 years depending on care and operating conditions, so a phased strategy can make sense, replacing the core equipment while preserving sound peripherals.

Key Factors That Affect HVAC Lifespan (Installation, Use and Maintenance)

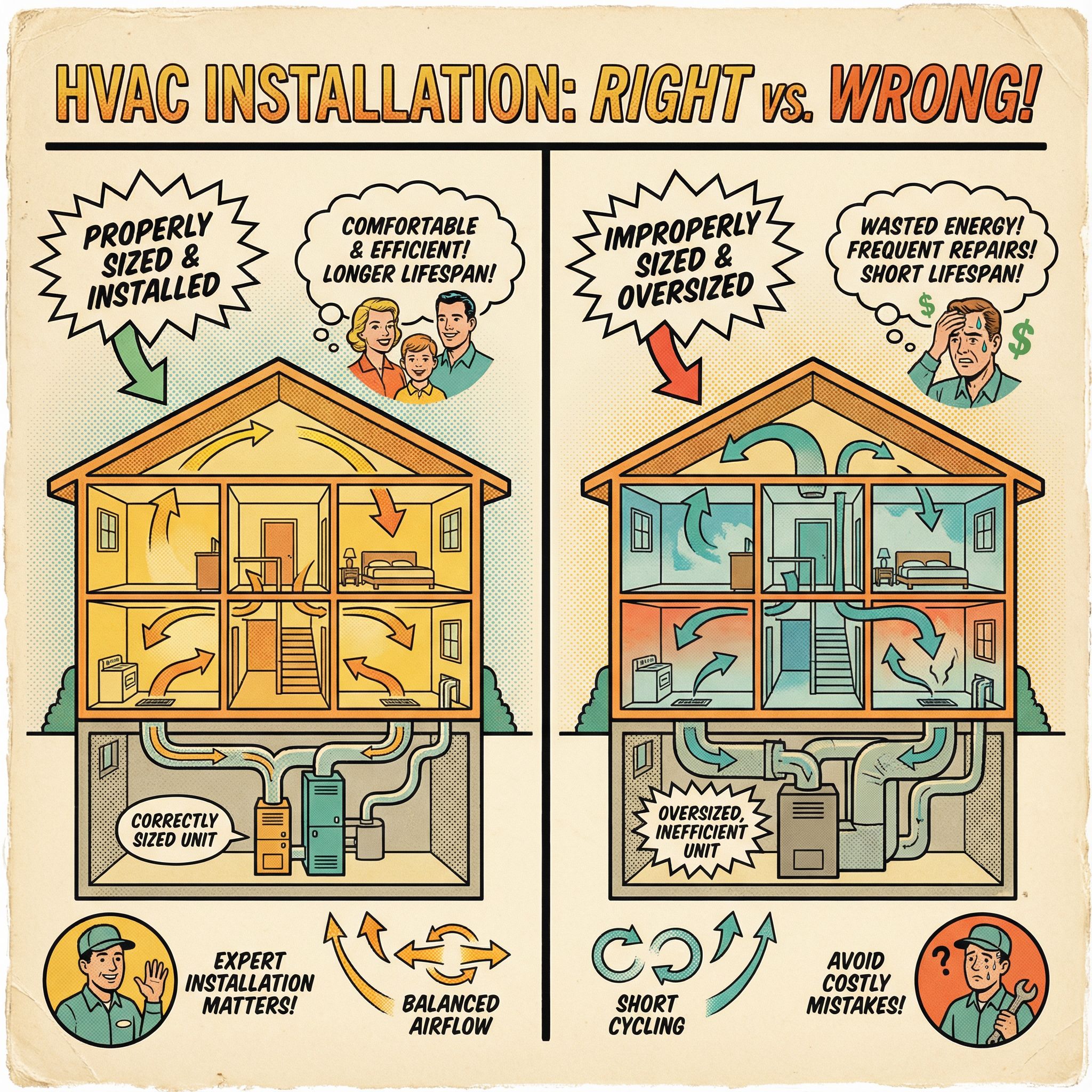

In our experience, nothing shapes HVAC lifespan more than proper installation and sizing. An oversized system short cycles, never settles into steady operation, and leaves humidity control lacking. That constant starting and stopping creates premature wear. Even a quality unit ages fast if installed poorly. A correctly sized, well set up system runs longer, calmer cycles that reduce stress on parts.

Maintenance is the other lever you control. Consistent professional tune ups and timely filter changes extend useful life by keeping airflow unobstructed. Skipped tune ups or dirty filters raise energy use and accelerate wear on compressors and blowers. It works like oil changes on a car: modest, regular care prevents the kind of strain that shortens a machine's life.

How Often Should You Service Your Home HVAC? Practical Maintenance Guidance

In our experience, most homes do best with a professional HVAC tune-up at least once a year, ideally before the season you lean on it most. If your system runs hard year-round, like a primary heat pump, plan on twice-yearly service.

- Change or clean air filters every 1-3 months, more often with pets or allergies.

- Keep supply and return vents unblocked.

- Clear leaves and debris around the outdoor unit.

- Verify thermostat settings and schedules.

Stop there for DIY. Leave refrigerant diagnostics and charging, major electrical repairs, any combustion or gas work, and compressor replacement to certified technicians. Always shut off power before basic cleaning, and use carbon monoxide detectors with gas or oil equipment. Think of maintenance like rotating tires: small, regular steps prevent big surprises.

When Replacement May Not Be the Best Move: Honest Tradeoffs and Alternatives

Replacement is not always the smartest first step. If your time horizon is short, typically fewer than about 7 years, the payback on a new system may outlast your stay. We often see better results by fixing the root cause instead of swapping the whole unit.

- Short ownership window: prioritize targeted repairs, duct sealing to curb losses, and a quality thermostat. Partial upgrades can bridge the gap without a full system change.

- Comfort or humidity complaints: these are frequently sizing, duct, or control issues. Oversized equipment short cycles and leaves moisture behind. A proper load calculation, duct sealing, airflow balancing, or relocating the thermostat can resolve problems.

- Maintenance myths: filters need changing every 1 to 3 months, not once a year. Skipping professional tune ups accelerates wear. Thermostat location matters. Correct habits can extend life and delay replacement.

Signs It's Time to Replace Your HVAC: Not Just Repair

When we advise homeowners, we use clear rules of thumb. In our experience at Budget Heating (BudgetHeating.com), these signs point to replacement, not another patch:

- Cost: if a single major repair is approaching roughly half the cost of a new system, replacement usually restores reliability and efficiency better than fixing again.

- Performance: frequent breakdowns, new hot or cold spots, poor humidity control, longer run times to reach setpoints, or louder-than-usual operation.

- Repair history: three or more significant repairs in about three years suggests replacement will be more economical and dependable.

Use these checks the same way a technician would to avoid throwing good money at recurring faults and to get comfort back on track.

Seasonal and Pre Replacement Checklist: What to Inspect Before a Tune Up or Quote

Use this quick pass each spring and fall before a tune up or when gathering replacement quotes. It speeds the visit and helps right size any new system.

- Ducts: Look for air leaks, loose joints, crushed runs, and missing insulation. Photograph problem spots. Ask for duct leakage testing and static pressure checks to verify airflow health.

- Building envelope: Check attic and wall insulation coverage, weatherstripping, and window condition. Note drafts. A tighter envelope lowers required capacity and reduces operating hours.

- Timing: Schedule inspections or quotes in the shoulder seasons, spring or fall, to avoid peak season delays and to get better availability and pricing.

- Logistics: If a change out will pause heating or cooling, plan temporary comfort options like space heaters or portable ACs.

Energy Efficiency, SEER2 and Regulatory Changes That Affect Replacement Timing

SEER is the seasonal efficiency rating for cooling, similar to miles per gallon for a car. SEER2, adopted in 2023, uses a tougher test that simulates real ductwork, so ratings read a bit lower than legacy SEER for the same equipment. In practice, SEER2 aligns closer to what we see in homes. For context: many older systems run around 8 to 12 SEER, today's minimums are roughly 14 to 15 SEER, mid tier is about 16 to 18, and premium exceeds 20 SEER. Expect the SEER2 label to be slightly lower for comparable performance.

U.S. minimum efficiencies changed on January 1, 2023 and vary by region, which can affect what is permissible to install during a replacement. Refrigerants are shifting as well: R 22 is already phased out, and R 410A is being transitioned away in favor of lower GWP options. As these rules advance, servicing older refrigerant systems often grows more expensive, making early replacement a practical choice.

Higher efficiency replacements frequently qualify for utility rebates, manufacturer promotions, and tax credits, which can shorten the payback timeline when paired with lower operating costs.

How to Decide, Plan and Pay for Replacement: Quotes, Sizing, Installation & Costs

Use this simple path to decide if repair or replacement makes sense, then line up a quality install and smart financing.

- Start with facts: check your current warranty status, look for unexplained energy bill increases, and confirm your refrigerant. Avoid investing further in R 22 systems due to higher future service costs.

- Do the math: compare long term repair plus operating costs to a replacement price, then subtract likely energy savings. Include any near term big repairs already on the horizon.

- Size it right: require an ACCA Manual J load calculation. A unit that is too large short cycles and feels clammy, like shoes two sizes too big.

- Select equipment: ask for Manual S to match capacity to the load. Consider two stage or variable speed compressors and ECM blowers for steadier temps and quieter operation.

- Address ducts when needed: for changes or known issues, ask for Manual D to confirm airflow design.

- Get written bids: proposals should list model numbers, efficiency ratings, planned duct work, permits, and commissioning steps. In our experience at Budget Heating (BudgetHeating.com), this is where the best contractors stand out.

- Insist on commissioning: evacuation to target micron levels, charge by weight, verify superheat and subcooling, measure airflow in CFM per ton, and perform static pressure diagnostics.

- Confirm protections: warranty coverage, registration requirements, available rebates, tax credits, and financing options.

- After install: schedule professional maintenance at least annually, use the correct filter and change it on time, and keep service and energy use records.

When to Replace Your HVAC: A Quick Checklist and Next Steps

Most systems should be evaluated at 10 to 20 years, sooner if you face repeat repairs, rising energy bills, comfort issues, or legacy refrigerants. Get annual inspections. When replacement looks likely, collect multiple bids that include Manual J sizing and a commissioning checklist so the new system performs as promised.

Act before peak season, review incentives and financing options (including Affirm), and aim for a spring or fall install. Our team has 30 plus years of HVAC experience and supports you from sizing through startup.

- Get a Custom Quote: line-item pricing at wholesale rates, free shipping on most systems.

- Talk to Our Team: U.S.-based phone support for sizing and brand choices.

- Shop Systems: Heat Pumps, Central AC, and Gas Furnaces.

hvac systems

hvac systems

Cooling

Cooling Heating

Heating Learning Center

Learning Center Money Saving Tips

Money Saving Tips Product and Brands Insights

Product and Brands Insights Buying Guides

Buying Guides State by State

State by State