Why Hotel Air Conditioning Determines Guest Comfort and Your Bottom Line

Guest comfort drives ratings and repeat bookings. In our experience, the room air conditioner has more influence on comfort than almost any other system: it sets temperature, dictates nighttime noise, shapes indoor air quality, and shows up every month on the energy bill. Choose well and you protect uptime and equipment life. Choose poorly and you buy headaches.

This Hotel Air Conditioner Buying Guide: Ensuring Optimal Guest Comfort is built for owners, GMs, facility directors, and developers who need clear, practical criteria. We explain how to select between common hotel AC options, right-size capacity, interpret efficiency ratings, and leverage smart controls. We also cover IAQ features like filtration and ventilation, plus installation details that prevent leaks and drafts, and maintenance practices that keep units reliable for 10 to 15 years. The purpose is simple, quieter rooms, healthier air, lower operating cost, and fewer complaints.

Why HVAC Choice Matters: Guest Experience, Noise, Efficiency and Serviceability

In hospitality, HVAC sets the tone for sleep quality, reviews, and operating costs. The right system must match room loads, run quietly, maximize energy efficiency and indoor air quality, and be easy to service. In our experience, systems that hit setpoint quietly and can be turned around quickly between stays consistently outperform.

Total cost of ownership matters more than sticker price. It includes installation complexity, energy use across seasons, routine maintenance and parts availability, expected service life, uptime risk, and how well controls integrate with property operations. A unit that is simple to maintain with common parts often costs less over time, even if the initial invoice is higher.

- PTAC or VTAC: strong fit for economy brands and retrofits, predictable installs, room-by-room replacement.

- VRF or ductless mini-split: best when quiet operation, zoning, and higher efficiency are priorities.

- Centralized systems: suited to large, complex properties that need coordinated comfort across many spaces.

Standardize models to streamline parts, training, and troubleshooting. Pilot test a wing or floor before a wide rollout to confirm acoustics, controls behavior, housekeeping access, and real-world energy use.

Energy Efficiency and Ratings: Understanding SEER, SEER2, EER and What They Mean for Hotels

SEER measures seasonal efficiency, cooling delivered per unit of electricity across a typical season. We treat it like a car's miles per gallon averaged over a whole trip. In 2023 the U.S. moved to the SEER2 test, which is stricter, so SEER2 numbers are typically lower than legacy SEER. Regional DOE minimums vary by region and capacity class, so compare models using the same test, preferably SEER2.

EER or EER2 is a snapshot at a single high load condition, useful for judging how a system handles hot afternoons. Hotels with heavy afternoon occupancy and frequent door openings benefit from strong EER or EER2 to help keep peak kWh in check.

Upgrading an older 10 SEER system to about 15.2 SEER2, roughly 16 SEER, can cut cooling energy 35 to 40 percent per room. Multiply that across rooms and common areas for meaningful portfolio savings. Variable speed compressors deliver quieter operation, better part load performance, and tighter humidity control, which means steadier temperatures and better guest sleep.

Room & System Sizing: How to Calculate Tonnage, BTUs and Per-Room Needs (Including 4-Ton Considerations)

Hotels succeed with sizing when the load is defined room by room, then rolled up to zones. We start by profiling every space: room counts and types, square footage, typical occupancy, wall openings like windows and doors, and available electrical capacity. Local climate and solar exposure by orientation matter, since a west-facing corner king behaves very differently than an interior double.

- Select system types by use: PTACs fit straightforward retrofits with exterior sleeves, while VTACs support ducted multi-outlet distribution. Verify closet space if choosing VTAC.

- Confirm infrastructure early: electrical service and breakers, condensate drainage path, sleeve dimensions, and any duct layout constraints.

- Consider 4-ton needs when a combined load serves multiple outlets or larger suites. A single larger VTAC or air handler can be appropriate only if the aggregated load and duct design support it.

Pilot and commissioning make the math real. Pilot representative rooms across orientations and floors, then commission each unit: verify airflow at all supplies, check setpoint accuracy, and confirm temperature uniformity across sleeping, desk, and bath areas under peak sun and peak occupancy. Inspect sound levels and condensate removal. Document results, adjust balancing or controls as needed, and train staff on basic operation and troubleshooting so performance stays consistent after turnover.

Costing, Budgeting and Payback: Comparing Initial CapEx to Lifecycle Energy and Maintenance Cost

Replacing a 10 SEER unit with roughly 15.2 SEER2 (about 16 SEER) typically cuts cooling energy 35 to 40 percent. In bill terms, a per unit annual cooling cost can drop from about $1,200 to roughly $780, a $420 per year savings. Over 10 years that is about $4,200 per unit. Mid step upgrades deliver proportionate savings.

Evaluate the full picture: purchase price plus installation, expected energy use, routine maintenance, and replacement timing, not just the upfront number. For payback, divide the upgrade's incremental cost by the yearly savings to find years to breakeven. In our experience at Budget Heating (BudgetHeating.com), owners who run this math across all units and set a maintenance budget make cleaner, faster decisions.

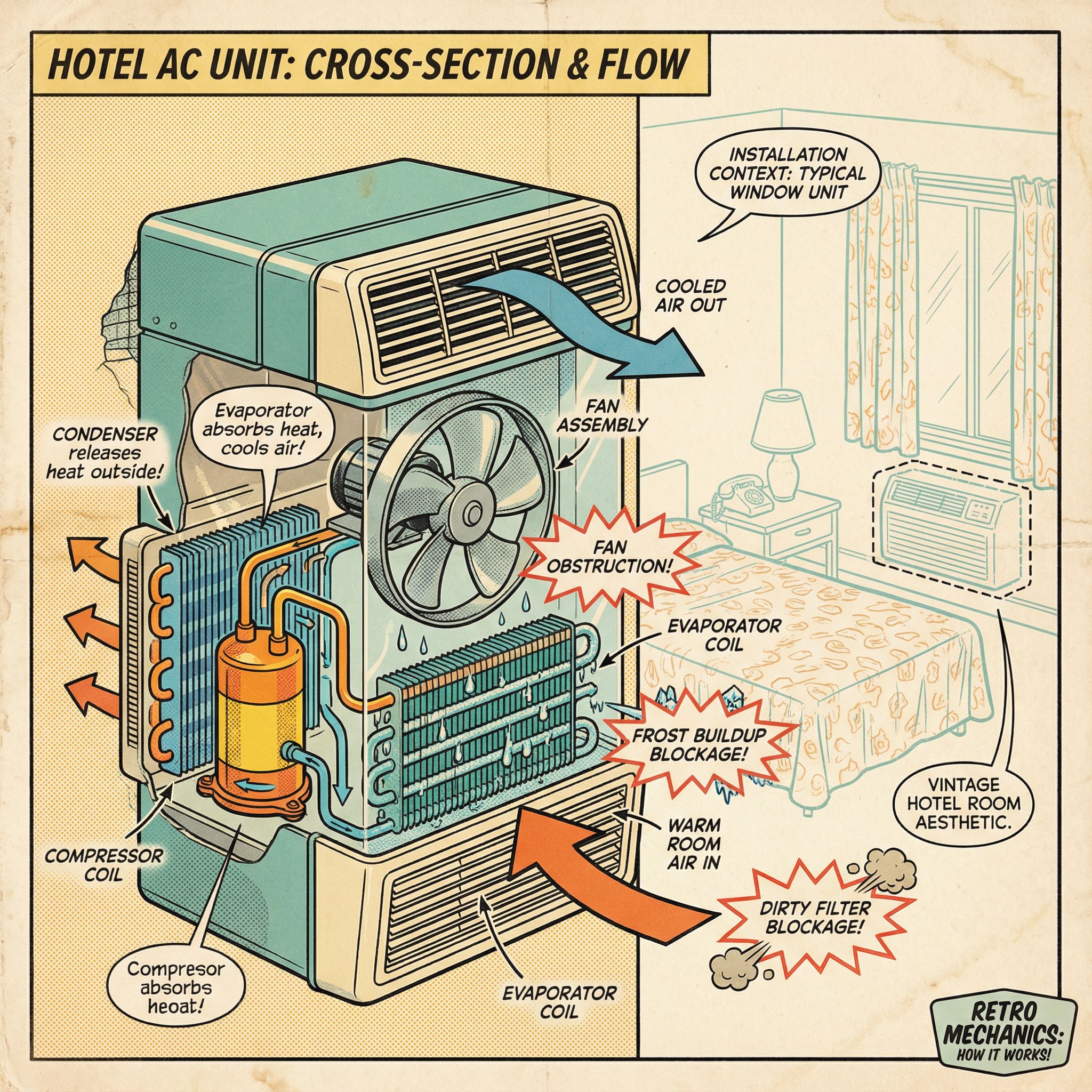

Maintenance, Troubleshooting and Common Failures: Preventing 'Not Blowing Cold' and Compressor Issues

We see most not blowing cold complaints trace back to airflow and basics. Think of the system like lungs, it needs clear airways. In-house staff can:

- Keep returns and outdoor coil clear of debris.

- Change or clean filters on schedule.

- Visually check coils and line-set insulation.

- Verify thermostat and control settings.

- Check condensate pans and drains for clogs.

Stop and call a licensed technician for refrigerant work, electrical changes, duct redesign, repeated breaker trips, ice on lines, oil stains, or any leaks. For routine prevention, maintain a simple log of dates, filter changes and observations, follow lockout or tagout and PPE when opening panels, and schedule seasonal professional preventive maintenance. At startup, confirm clean filters, unobstructed airflow and proper controls to protect the compressor and avoid weak airflow or hot air.

Regulatory, Refrigerant and Regional Considerations: SEER2 Rules, A2L Refrigerants and Climate Priorities

In 2023, the U.S. shift to SEER2/EER2 changed published efficiencies and raised minimums by region and capacity. We verify local thresholds and any utility program criteria before procurement, since a model that passes in one zone may not in another. The AIM Act is also moving equipment to lower GWP A2L refrigerants such as R-32 and R-454B. That transition brings updated safety standards that can affect where units are placed and how they are serviced, so plan the install around those rules. Match equipment to climate: hot humid areas benefit from strong dehumidification and variable speed control; hot dry regions prioritize high sensible capacity and corrosion protection; cold climates need low ambient heat pumps or dependable auxiliary heat. Always confirm local building and fire codes.

Tradeoffs & When Certain Hotel AC Options Aren't Right (Honest Limitations and Better Alternatives)

In practice, we see two units confused often. PTACs are single zone, visible under the window. VTACs sit in a closet with short duct runs to supply grilles, which tends to distribute air more evenly. Common mistakes include assuming PTAC and VTAC are interchangeable, expecting one through wall unit to condition a whole suite, and choosing solely on upfront price. Undersizing invites short cycling and poor dehumidification.

- For a bedroom plus living area, a single PTAC is not ideal. A VTAC with short duct runs, or using more than one single zone unit, delivers more even comfort.

- If the visible grille under the window clashes with design goals, PTAC will disappoint. A VTAC in a closet with ducted outlets keeps equipment out of sight.

- Where humidity loads are high, undersized gear will short cycle and leave rooms clammy. Select the correct capacity and avoid one size fits all decisions rather than chasing the lowest bid.

Procurement, Warranties and Vendor Selection: What to Require in Your RFP

Standardize early: list approved models, refrigerant, voltage, controls, filter sizes and line set lengths to avoid mixed fleets. Require factory authorization, 10-year compressor and 5-year parts warranties, plus access to the vendor service portal. In our experience at Budget Heating (BudgetHeating.com), these clauses reduce downtime and keep bids truly comparable. Also ask for startup checklists, O&M manuals and training. Specify a spare parts kit with stated lead times and local service coverage within 50 miles.

Conclusion: Choose the Right-Capacity, Quiet, Efficient System, Then Pilot, Commission and Standardize

Pick right-capacity equipment that holds setpoint quietly, meets or exceeds SEER2 and EER2, supports IAQ, and offers guest-friendly controls with strong warranties. Evaluate total cost of ownership, pilot before rollout, then document commissioning and service to limit disruption.

We know standardizing across properties is high stakes, and our U.S.-based team with 30+ years of hands-on HVAC can help you validate sizing, compare options, and plan a smooth pilot.

- Get a Custom Quote

- Talk to Our Team by phone for fast, U.S.-based sizing help

- Shop Heat Pumps, Mini Splits and PTACs

- Request a Pilot and Commissioning Checklist