Crazy HVAC Stories: Why Maintenance Isn't Just About Comfort

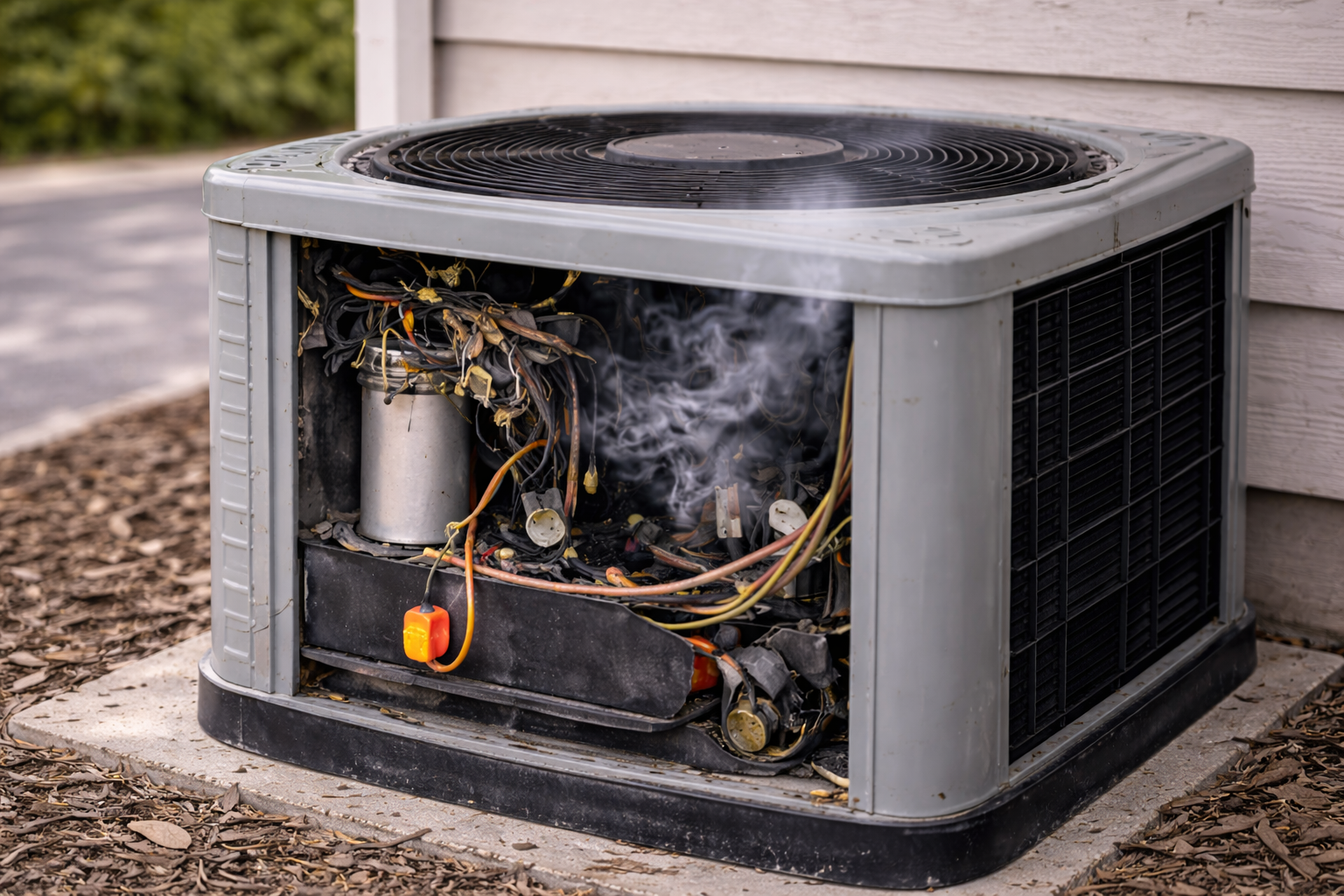

Ever hear a condenser squeal at 2 a.m., then go quiet right before a trip? Or watch an attic unit drip through drywall during a summer storm? The wildest HVAC tales usually start with small clues: a burnt odor, a breaker that keeps tripping, frost on a line, a rattle that comes and goes. Maintenance is not just about comfort. It protects safety, preserves efficiency, and heads off surprise failures. Regular service finds hazards before they become emergencies, like loose electrical connections, clogged condensate drains, overworked blower motors, and low refrigerant that can overheat compressors.

Think of a tune up as a seatbelt for your system, always on and mostly invisible until you need it. This article lines up dramatic real world examples, followed by the simple steps that would have prevented them. The goal is practical prevention: what to listen for, what to look at, and when to schedule service so the next HVAC story at your house is a quiet one.

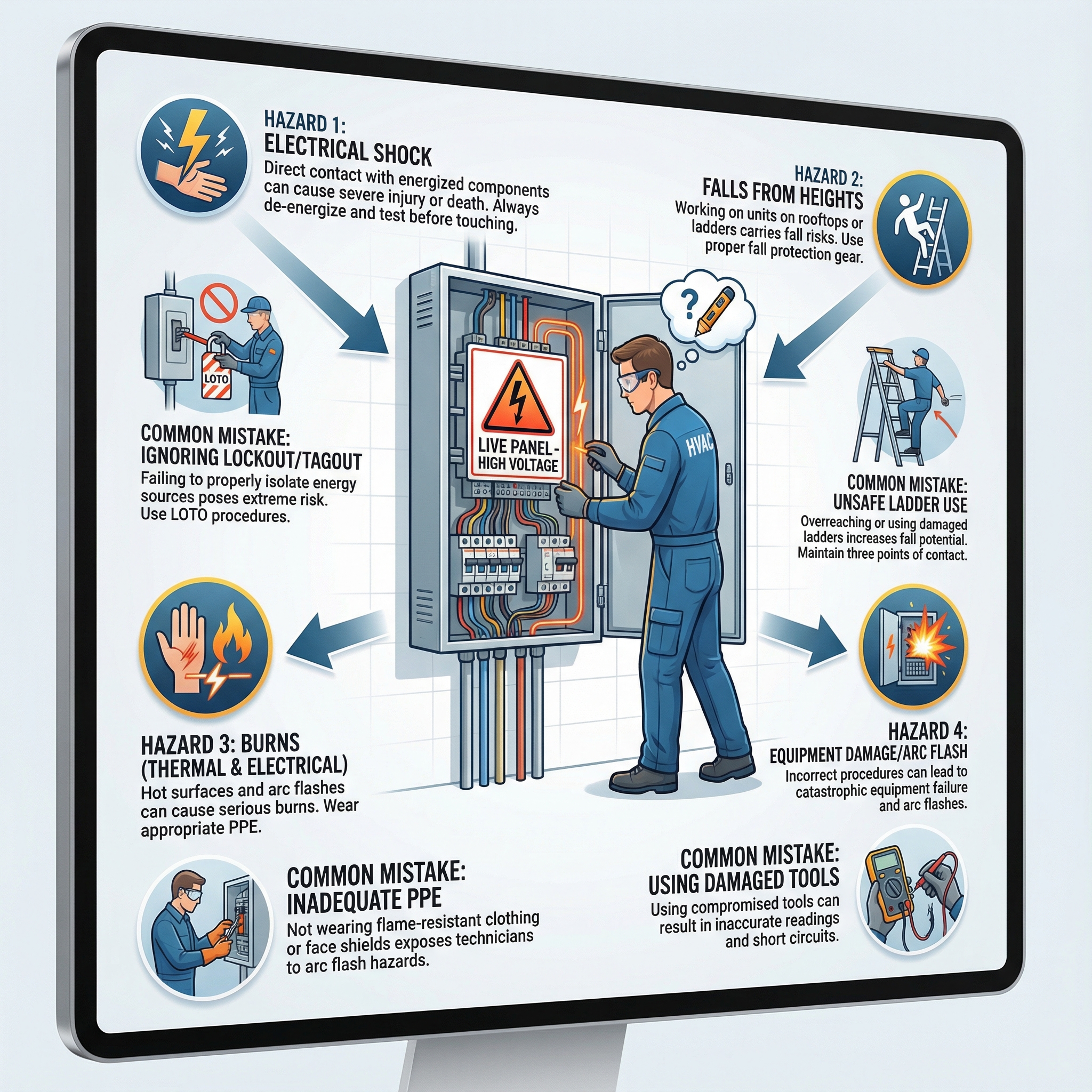

Why HVAC Maintenance Can Be Dangerous: A Quick, Sobering Overview

What looks like simple upkeep can turn risky fast. We routinely see accidents trace back to rushed troubleshooting that skips safety checks, missing or wrong protective gear, and lack of training that hides hazards in plain sight. Tight, unventilated spaces without gas detection allow carbon monoxide and chemical buildup. The most preventable trigger is skipped lockout and tagout. Proper lockout and tagout means de energize the circuit, apply a physical lock and a clear tag at the disconnect or breaker, verify zero energy with a meter, then recheck before reassembly. It is the difference between a controlled job and an electrocution or arc event. Personal protective equipment for HVAC work is not optional: insulated gloves, eye and face protection, cut resistant sleeves, hearing protection, and respirators with the right cartridges when brazing, cleaning coils, or handling refrigerant, plus insulated hand tools rated for the voltage.

- Myth: Bigger equipment is better. Reality: oversizing short cycles, drives humidity problems, and adds wear.

- Myth: Blocking returns or closing doors helps. Reality: pressure imbalances can back draft combustion appliances.

- Myth: Closing vents saves energy. Reality: static pressure rises and components suffer.

- Myth: Filters rarely need changing. Reality: dirty filters cause freeze ups or overheating.

- Myth: Only call on failure. Reality: preventive service avoids emergencies and hazards.

- Myth: SEER is all that matters. Reality: sizing, ducts, and commissioning drive real results.

- Myth: Skip tune ups if it seems fine. Reality: hidden wear leads to sudden failure.

- Myth: Cranking the thermostat speeds heating or cooling. Reality: it only runs longer.

- Test air, ventilate confined areas, and use CO monitoring.

- Follow manufacturer instructions and code requirements.

- Use insulated tools and task appropriate PPE every time.

- Perform lockout and tagout and verify zero energy.

- Recover and handle refrigerant per rules to avoid exposure and violations.

Story: The Electrocution Near Miss: When Power Isn't Off

We once arrived just after a homeowner killed his AC at the thermostat and popped the outdoor panel. His screwdriver grazed a live lug, there was a sharp pop and bright flash, and the tool tip vanished. He was lucky. That is electrical shock and arc flash territory when a panel is live or a circuit is mis isolated.

The simple safeguard would have prevented it: always shut off power at the breaker and the outdoor disconnect before opening any panel. For light cleaning or access, wear basic PPE like gloves, safety glasses, and a dust mask, and keep bystanders back. Professionals go further with insulated gloves and tools. Treat every cabinet like a loaded spring. If you are not certain power is off, do not open it.

Story: Carbon Monoxide Almost Claims a Family: Combustion Hazards

We arrived to a two story home after midnight when a hallway CO alarm started chirping. The family felt dizzy but thought it was a flu. Our meter spiked near the furnace. A hairline crack in the heat exchanger was pushing exhaust into the supply air, and a bird nest had partially blocked the flue, creating back drafting. That mix turned the house into a sealed bottle of CO, the gas you cannot see or smell.

The only reason this did not end tragically was a working CO detector outside the bedrooms. Keep CO detectors on each level and test them monthly, replacing batteries on schedule. Combustion appliances must be checked for cracked heat exchangers, blocked flues, or any condition that can cause back drafting. A quick inspection and proper venting can be the difference between a scare and a catastrophe.

Story: The Duct Cleaning Disaster: Contamination Spread and Moving Part Hazards

We were called after a DIY duct cleaning left a home smelling like a pool and everyone coughing. The contractor blasted a strong coil cleaner into returns, then ran the blower to dry things out. Instead, the mist coated supply runs and rooms with chemical residue. Misused disinfectants can burn skin and eyes, and aerosols linger in the airstream, especially on porous duct liners.

Worse, they brushed a moldy drain pan and coil while the fan was on. That turned settled growth into confetti, spreading spores through every register. Ducts, coils, and pans can harbor biofilm that must be contained, not scattered.

Finally, someone reached past a loose panel while the unit was running. Fans, belts, and wheels do not slow down for fingers, jewelry, or sleeves, and impact injuries happen in a blink. Safe cleaning starts with lockout, containment, and the right, compatible chemicals in measured dilutions.

Story: The Refrigerant Mistake: Toxic Exposure and Frostbite Risks

We once arrived after a homeowner tried to top off refrigerant with a borrowed gauge. When they cracked a service valve, the line ruptured and a white cloud filled the room. The vapor displaced air, they coughed and wheezed, and a droplet on the forearm burned cold, true frostbite on contact, like touching dry ice. Refrigerants sit under high pressure and boil at very low temperatures, so a small mistake becomes both toxic exposure and a cryogenic injury. Never attempt to handle or add refrigerant, only licensed HVAC professionals should connect gauges or charge systems. Even a minor leak or line rupture can escalate fast with respiratory symptoms and skin damage, and the risks do not stop once the cloud dissipates.

When DIY Goes Wrong: Ladder Falls, Rooftop Accidents and When Not to Tackle HVAC Yourself

After 30 plus years on rooftops and in attics, we have seen too many weekend projects end with a slip and a sprain. Falls from ladders, roofs, or attic access points are a common and serious injury source during maintenance. Here is the honest line between what to leave alone and what to hire out.

- Anything that requires a ladder, rooftop work, or crawling through an attic. The injury risk outweighs any DIY savings.

- Cooling season tasks: proper coil cleaning, verifying refrigerant charge, inspecting the condensate system, checking the blower and electrical safety. These belong in a professional cooling visit.

- Heating season tasks: inspecting the heat exchanger and burners, testing ignition and safety controls, and verifying venting. These are professional heating visit items.

Best practice is biannual professional service, one cooling visit and one heating visit for deep cleaning and safety checks. A common misconception is that a quick rinse or a visual peek equals maintenance. Real service includes the checks listed above, which catch problems before they become failures.

Concerned about price? Costs vary widely by region and scope, so blanket ranges are not useful here. If you insist on DIY, keep both feet on the ground and skip any task tied to ladders, roofs, or tight attic access.

Story: Asbestos and Hidden Hazards: Finding Old Materials You Didn't Know Were There

We once pulled a rusted return drop from a 1950s home and the duct wrap looked ordinary. A quick sample told a different story: asbestos-laced insulation and lead-painted boots tucked out of sight. Older systems and ducts can contain asbestos, lead paint, or other legacy hazards that demand specialized handling. Disturbing them turns a quiet risk into airborne fibers and chips. Before cutting, sanding, or replacing any cabinet, plenum, or transite run, get the suspect materials tested by a certified lab. If results come back positive, schedule abatement by a licensed contractor, then proceed with the HVAC work. Think of it like checking a wall for wiring before drilling: a small pause up front prevents a dangerous and costly surprise.

A Practical HVAC Maintenance Safety Checklist: What Every Homeowner Should Do

Your HVAC runs safely and efficiently when airflow, filtration and drainage are kept in check. Think of airflow like your home's lungs. Clear paths in and out keep parts cool, dry and clean, which prevents breakdowns and safety hazards.

- Monthly basics: Inspect filters, replace every 1 to 3 months based on use and MERV compatibility. Keep supply grilles and return paths open, avoid blocking with furniture or closed doors. Ensure adequate return air for the rooms you use most. Monitor indoor humidity, aim for about 30 to 50 percent, and investigate persistent condensation or musty odors.

- Drainage and water checks: Confirm the AC condensate line is draining. Look for water around the air handler or furnace and address clogs promptly.

- Ducts you can see: Inspect accessible ducts for disconnections. Arrange professional sealing or insulation where needed to protect efficiency and comfort.

- Spring prep: Clear leaves and debris around the outdoor unit, keep 18 to 24 inches of breathing room. Gently rinse the condenser coil and ensure the unit is level.

- Fall prep: With power off, vacuum around the furnace or air handler, confirm grilles are open, and get ready for heating season.

- After severe weather: Remove ice or debris from outdoor units and consider surge protection on the HVAC circuit.

- Red flags that require a pro: Burning or chemical smells, repeated breaker trips, ice on lines or coils, water leaks, any carbon monoxide alarm activation, rapid humidity swings, or new noises.

- Annual professional service: A tune up with coil cleaning, electrical checks and combustion safety testing reduces emergencies and extends life. In our experience at Budget Heating (BudgetHeating.com), proactive cleanings prevent the majority of costly mid season calls.

- Airflow and sizing matter: Poor airflow or oversizing leads to short cycling, poor dehumidification and overheating, which can become safety issues. High efficiency equipment only delivers when it is sized, installed and maintained correctly.

- Efficiency and regulations: SEER2 ratings use a higher test static pressure that better reflects real ducts. Compare like for like, SEER2 to SEER2, and ask about commissioning. Regional efficiency minimums vary, so verify replacement equipment meets your region's rules and that labels and documentation match.

Routine maintenance prevents invisible wear, keeps comfort steady and lowers long term costs. A little attention each month goes a long way toward fewer emergencies and safer operation.

Lessons Learned from HVAC Horror Stories: Stay Safe and Call the Right Pros

Most HVAC horror stories start with preventable gaps: live electrical parts, falls, refrigerant or CO exposure, asbestos, mold, chemical hazards, and entanglement. Inspections, trained techs, proper PPE, and simple habits like clean filters, clear vents, and working CO detectors keep systems safer and longer lived. If you are deciding on repair or replace, our team with 30+ years in the field and 200,000+ orders fulfilled will guide you to the right solution.

- Get a Custom Quote

- Talk to Our Team by phone, U.S. based technical support

- Shop Heat Pumps, AC Systems, and Ductless Mini Splits

- Wholesale pricing, many systems ship free, financing with Affirm

HVAC maintenance

HVAC maintenance

Cooling

Cooling Heating

Heating Learning Center

Learning Center Money Saving Tips

Money Saving Tips Product and Brands Insights

Product and Brands Insights Buying Guides

Buying Guides State by State

State by State HVAC Systems

HVAC Systems