Central AC Installation Costs: Single-Story vs Multi-Story, What to Expect

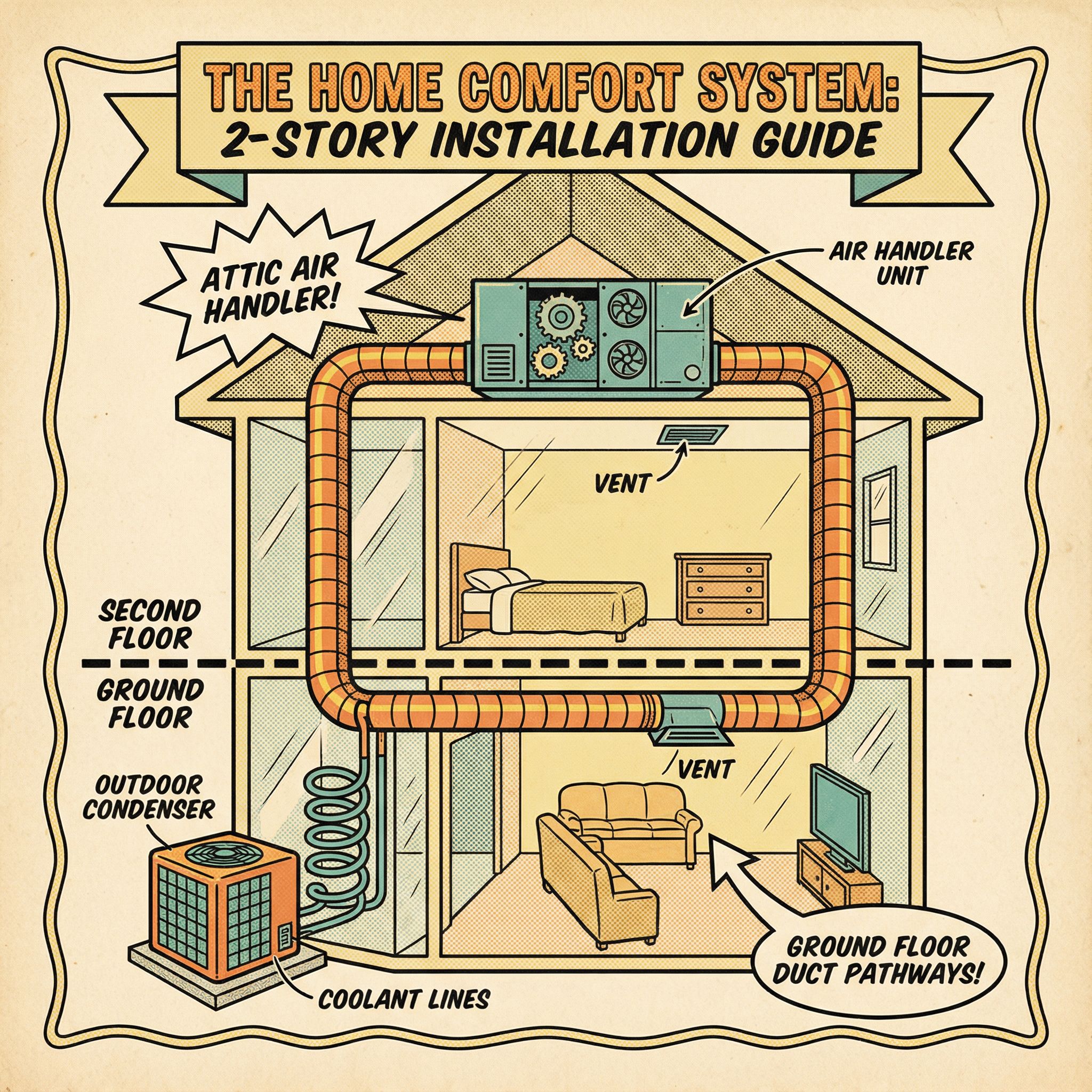

Installing central air is a major comfort upgrade, and the layout of your home drives both price and long-term performance. Over three decades in HVAC work, we have seen the same rule hold true every time: the layout-driven cost principle. The more floors air and refrigerant must travel, the more planning, materials, and labor it takes. Single-story homes are typically quicker and less expensive to outfit because equipment, ducts, and rooms sit on one level. Multi-story homes add vertical chases, longer line sets, more supply and return paths, and tighter static pressure targets to keep upstairs and downstairs even. That extra complexity influences comfort and operating cost for years.

In this guide we will outline where costs diverge: placement of the air handler or furnace coil, duct routing and returns by floor, refrigerant line lengths and evacuation time, condensate management, electrical runs, and options like zoning or added returns to tame hot second floors. We will also note permitting and crane or attic access factors that can change labor hours. Think of airflow like a delivery route: a single cul-de-sac is simple, multiple stacked streets need more fuel and time. Understanding these drivers helps you read bids clearly, avoid shortcuts that hurt performance, and choose the right scope for your home.

Quick Cost Snapshot: Typical Installed Prices for Single-Story vs Multi-Story Homes

Here are fast installed price ranges you can use to anchor expectations.

- Single-story: about $4,000 to $7,000 installed.

- Multi-story: roughly $6,000 to $10,000+, with many projects reaching $16,000+ depending on scope and region.

Expect a consistent premium for multi-story homes, even when square footage is similar. Multi-story jobs commonly run at least about $2,000 more, and often $2,000 to $9,000+ higher due to added labor and materials. The sticker shock many see on multi-story bids usually reflects legitimate added complexity, not overcharging: vertical refrigerant or duct runs, building or using chases, and the finish repairs that follow. This pattern tracks with layout-driven costs, where the path your equipment and lines must travel influences time and materials far more than the raw size of the house.

Why Multi-Story Homes Often Cost More to Cool and Install

Layout drives cost, and when a home stacks living space on multiple levels, every step takes longer. Getting air and refrigerant upstairs is like threading a cable through a multi level maze, and we routinely see tighter routing, more penetrations, and tougher attic or roof access.

- Vertical duct and refrigerant runs add length, fittings, and lift. That increases labor, materials, pressure drop, and charging complexity.

- Balancing between floors takes extra returns on the upper level, careful duct sizing, and sometimes added components or framed chases to move air correctly.

- Installation time drivers include building chases, setting attic platforms, using a crane or staging for rooftop or tight lot sets, and longer commissioning to dial in airflow and refrigerant charge.

- Penetrations between floors need sealing and firestopping, then finish repairs, which pushes schedule and cost.

By contrast, single story homes usually have shorter, more direct runs with easier attic, crawlspace, or basement access, which trims labor and materials.

Cost Examples by Home Size and Number of Stories (Realistic Scenarios)

Square footage is the starting point, not the finish line. Stories, layout, access, and the condition of existing ducts often swing costs more than raw size.

- Single story, straightforward retrofit: typically 4,000 to 7,000.

- Similar size, multi story: commonly 6,000 to 16,000 or more when ducts or zoning are involved.

- Mid size around 1,800 sq ft: can land in the mid to high five figures if extensive ductwork or multi zone control is required.

In our experience at Budget Heating (BudgetHeating.com), attic or crawlspace access, tight basements, and tricky chases add time and materials, which drives price. Identical designs can still price out differently across markets because labor rates and permitting vary, so the same scope in two cities may not cost the same.

Sizing & Efficiency: Why Manual J, Manual D, and SEER2 Matter for Cost and Comfort

In our experience, Manual J must consider climate, window area, insulation, ceiling heights, and layout. Right sizing prevents short cycling, poor dehumidification, and uneven rooms, especially in multi-story homes. Pair it with Manual D to size and balance ducts so airflow stays on target.

SEER2 is the newer test, so ratings read lower than legacy SEER. DOE minimums: about 13.4 SEER2 in northern states and 14.3 SEER2 for smaller splits in the SE and SW, larger sizes differ. Upgrading SEER2 cuts kWh by about 1 - baseline/new, with stronger payback in hot climates. Options range 13.4-14.8 SEER2 up to variable-speed 18-21.5. SEER matters, but installation quality, duct condition, and sizing are equally critical.

Typical Cost Breakdown: Equipment, Ductwork, Labor, and Permits

A fair HVAC bid breaks into clear buckets so you know where the dollars go. Equipment covers the outdoor condenser and the indoor air handler or coil. Higher SEER or SEER2 ratings and variable speed features cost more upfront, and larger capacities or premium models raise the installed price.

Ductwork is often the sleeper cost. Replacement, sealing, insulation, or re routing add quickly, especially in multi story homes with longer runs. Think of ducts as the air's highway: more lanes, detours, and distance mean more material and time. In our experience at Budget Heating (BudgetHeating.com), the ductwork line can swing the total more than any other after the equipment itself.

Labor is a major line item. Longer runs, attic or roof access, tight spaces, and proper balancing require more skilled hours, which is why layout drives cost. Permits and inspections are common and vary by municipality.

- Ask for line item pricing: equipment, ducts, electrical, permits, labor, and haul away so bids are truly comparable.

How Home Layout & Access Affect Installation Time, Price, and Planning

Layout and access drive labor. An air handler in an attic, crawl space, basement, or tight closet sets crew size, ladder time, and how we stage materials. In multi-story homes we account for vertical chases, safe roof or attic entry, and routing. Routing can feel like threading a needle through walls. Details that move price: line-set length and path, condensate drainage or a pump, attic service platforms, and return-air pathways. Beyond ductwork already covered, these factors shape schedule and bid.

- Map equipment and ducts. Note tight openings and clearances.

- Plan logistics: clear paths, protect finishes, safe attic or roof access.

- Ask contractors how multi-story changes labor: chases, routing, finish repairs.

Ducted vs Ductless vs Zoned Systems: Honest Tradeoffs and When Each Makes Sense

Central ducted AC is the right fit when a home already has well designed, tight ductwork and you want whole home comfort with one system. In our field work we routinely find that old, leaky, or undersized ducts are the bottleneck, and reusing them is a false economy, especially in multi story homes where air must travel farther. Replacing bad ducts can be worth the investment.

- Homes without ductways: running new chases can be costly. Multiple ductless heads can be cheaper.

- Spot cooling an addition or garage: a small ductless or mini split is sensible.

- Historic finishes: if opening walls is disruptive, consider ductless mini splits, a separate small system, or targeted envelope upgrades.

Zoning, motorized dampers with multiple thermostats, or separate systems can solve upstairs and downstairs comfort gaps. The tradeoff is added equipment, control parts, and design and commissioning labor. Done well it works, but it is not the lowest complexity path.

Ductless mini splits avoid ductwork and shine in retrofit zones, although many indoor heads or multiple systems can add up compared with a properly designed central system. Ultimately the layout drives cost and practicality.

How to Compare Contractor Quotes: A Checklist of Questions and Safety Items

- Get 2 to 3 bids listing system type, brand and model, SEER2, capacity, indoor and outdoor unit details, and warranties.

- Verify bids meet regional SEER2 minimums, include code compliant electrical, and that the contractor will pull permits and manage inspections.

- Have ductwork evaluated for leaks, damage, insulation quality, and sizing, and request leakage or static pressure testing where feasible.

- For multi story homes, request a per floor or per zone cost breakout.

- Require licensed professionals for 240V wiring, disconnects, brazing, vacuuming, and charging refrigerant circuits to preserve safety and warranties.

- Refrigerant work must be performed by EPA 608 certified technicians.

- If the air handler shares space with a combustion appliance, insist on licensed gas piping, venting, and CO checks.

- Ask for commissioning documentation: refrigerant charge, airflow metrics, thermostat and zoning checks, and registration of equipment warranties.

- At closeout, receive operator manuals, filter sizes and locations, basic maintenance instructions, and recommended service intervals.

Next Steps: Get a Manual J, Compare Detailed Bids, and Schedule a Local Quote

Single story installs are usually quicker and cheaper, while multi story homes add design and labor complexity that can raise cost about 10 to 50 percent depending on scope. The best path is simple, insist on Manual J and Manual D, get multiple line item bids, evaluate duct condition, and consider zoning where it makes sense. Choose contractors comfortable with multi level design, zoning, and attic or roof work, and require commissioning to cut down on callbacks.

You are making a big decision with a lot of variables. We make the technical side clear so your local quote is accurate and the system performs as promised.

Our team has 30 plus years in HVAC, 200,000 plus orders fulfilled, and U.S. based support. We will help you compare bids, right size equipment, and build a materials list at wholesale pricing with full factory warranties.

- Get a Custom Quote: share your basics, we apply Manual J guidance and build a detailed materials list.

- Talk to Our Team: U.S. phone support for fast answers on zoning, ducts, and equipment pairing.

- Shop Heat Pumps and AC Systems: Goodman, Rheem, Bosch, and Gree, with free shipping and Affirm financing.

Cooling

Cooling Heating

Heating Learning Center

Learning Center Money Saving Tips

Money Saving Tips Product and Brands Insights

Product and Brands Insights Buying Guides

Buying Guides State by State

State by State HVAC Systems

HVAC Systems