Why Is My Electric Furnace Blowing Cold Air? A Quick Overview

If your electric furnace is blowing cold air, comfort drops quickly and the unit may run longer without actually heating, driving up energy bills and wear on components. In our field experience, quick, orderly checks usually pinpoint the cause while keeping you safe.

Persistent cold air operation can strain heating elements, high limit switches, sequencers, and control boards, and it can harm indoor air quality by moving unconditioned air. Tackle low risk items first, then step deeper, so you avoid needless trips of safeties and do not chase symptoms. Think of it like checking a light switch and breaker before replacing the bulb, simple steps often reveal the issue fast.

- Thermostat mode and fan settings

- Power supply and breakers

- Heating elements and sequencers

- Safety or high limit trips due to overheating

- Air filter condition and airflow

- Condensate drainage for systems with coils

- Duct integrity

How an Electric Furnace Works: The Parts That Make Heat (and Stop It)

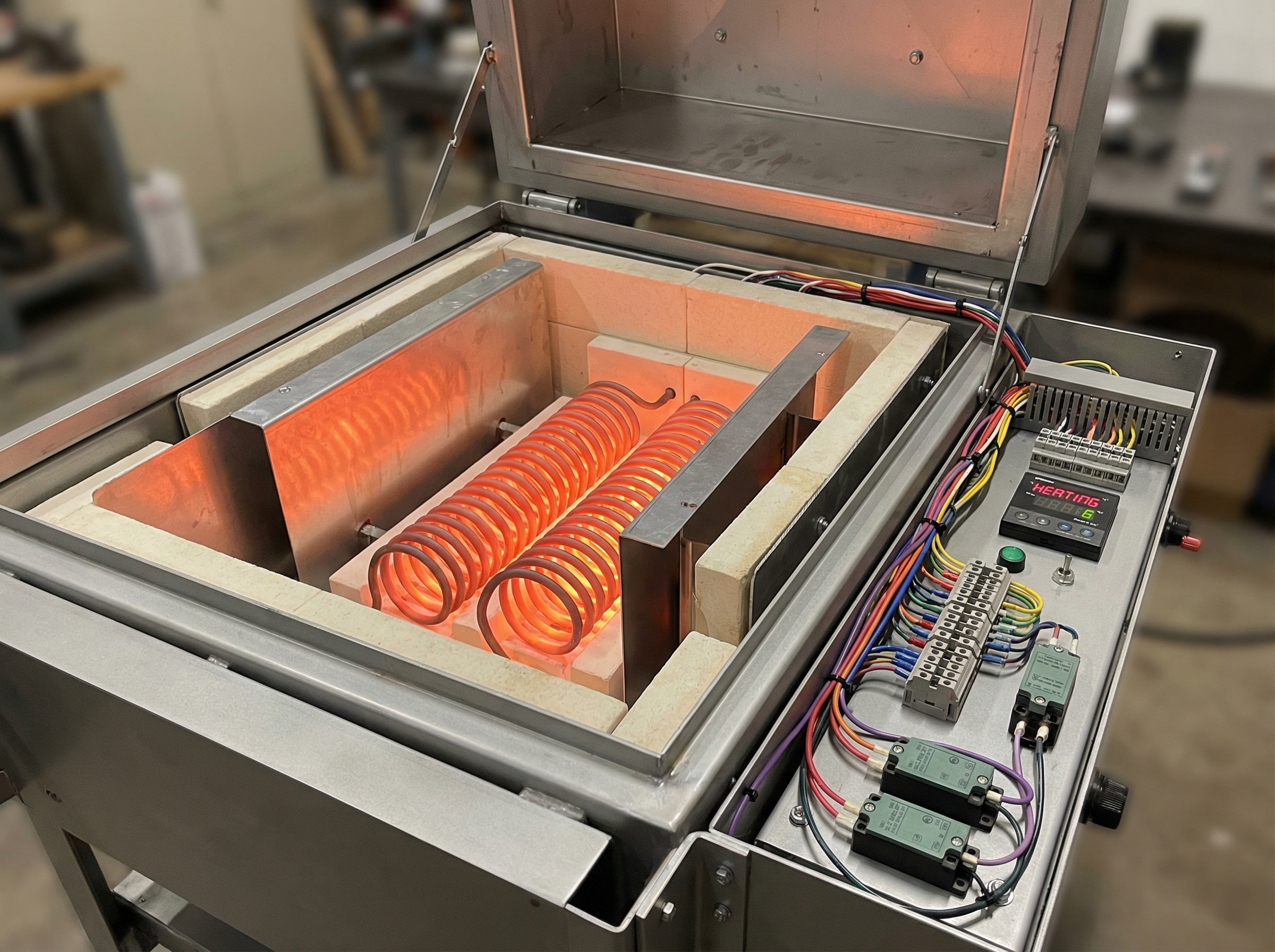

Electric furnaces make heat with resistance elements, basically oversized toaster coils that glow hot when powered. A blower pushes room air across those heat strips and into the ductwork. To match demand without a giant inrush of power, staging controls bring elements on in steps. Depending on the model, this is handled by sequencers, relays, or contactors that switch individual strips on and off.

Airflow is the lifeline of an electric furnace. If the blower is weak or obstructed, less air crosses the elements. Common culprits are a failing motor capacitor, worn bearings that slow the wheel, or debris in the blower housing. Low airflow does two things at once: outlet air can feel cooler, and the elements run hotter internally. To protect the furnace, a high limit switch opens when it senses overheating. That cuts power to the elements while the blower can continue to run, so you feel room temperature air at the registers. Restore proper airflow and the limit will reset, allowing heat to return.

Common Reasons an Electric Furnace Blows Cold Air (the short list)

From field work, we see cold-air complaints fall into a few clear buckets. Use this short list to narrow it quickly.

- Thermostat or settings: wrong mode, fan set to On, weak batteries, or an off-kilter schedule.

- Power loss to heat elements: tripped breaker, blown fuse, service switch off, or door switch not engaged.

- Airflow restrictions that open safety limits: clogged filter, closed registers, dirty coil or blower wheel.

- Failed high-voltage parts: burned elements, bad sequencer, faulty contactor, or a control board issue.

- Duct or condensate complications: leaks pull in cold attic or crawl air, or a float switch stops heat while the blower keeps running. Check the air path and safety devices.

Start with settings and power, then airflow, then components.

Quick Checks You Can Do Right Now (safe DIY steps)

Work through these homeowner-safe steps in order. Each one rules out a common, easy-to-fix cause before you consider a service call.

- Thermostat basics: set mode to HEAT, fan to AUTO, and raise the setpoint 3-5 degrees above room temperature. If the thermostat uses batteries, replace them and review schedules or recent setting changes.

- Airflow first: remove and inspect the return filter. Replace if dirty, typically every 1-3 months. Open all supply and return registers and clear furniture, rugs, or debris. Think of airflow like breathing through a pillow, the system struggles when it is blocked.

- Condensate and drain: on systems with an indoor coil, check the condensate pan for standing water. Clear any visible clog at the drain line. A full pan can trip a float switch that stops heat while the blower keeps running.

- Power and switches: confirm the service switch at the furnace or air handler is ON. At the breaker panel, reset a tripped breaker once only. If it trips again, stop there.

- Observe behavior: note if the blower runs nonstop, if you feel brief warmth before it goes cool, and whether any LEDs flash an error code. Record what you see and hear.

These quick checks eliminate the usual suspects and provide useful clues for deeper diagnostics.

Tradeoffs & Considerations: When an Electric Furnace Might Not Be the Best Choice

Electric resistance furnaces are 100% efficient at the register, and there is no SEER rating for resistance heat. In very cold climates they get costly and can struggle to maintain comfort, especially with leaky or uninsulated ducts that trigger limit trips and short cycling. We see them fall short when winters sit below your design temperature, kWh rates are high, or the duct system is marginal.

Better fits include a gas furnace or a cold climate heat pump. Many pair a heat pump with electric strips as backup for steadier comfort and lower operating cost. When vetting bids, ask for a Manual J load, verify heat strip kW against your design temperature, and request duct static pressure and leakage testing. For efficiency comparisons, review the heat pump's HSPF2 and the blower's FER, since those ratings shape overall performance in a way a resistance furnace alone cannot.

Thermostat Problems: Settings, Batteries, and Wiring to Check First

The thermostat is the traffic cop for your furnace, so small missteps can look like a major failure. Confirm it is in HEAT, not COOL or OFF. Make sure the fan is on AUTO, not ON, which will blow room temperature air between cycles. Raise the setpoint several degrees above room temperature. Replace weak batteries, since low voltage can cause erratic calls for heat or miscalibration.

If settings are right and you still get cold air, check for a loose thermostat wire or an older stat that is incompatible with multi-stage electric heat. In our experience at Budget Heating (BudgetHeating.com), upgrading to a properly matched thermostat clears many furnace complaints. Persistent issues warrant professional testing to verify calibration and staging control before chasing parts.

Airflow Issues: Filters, Vents, Blower Problems and Why They Cause Cold Air

Airflow is the lifeblood of a furnace or heat pump. When it is restricted, heaters overheat and shut off on safety limits, then the blower keeps moving air that feels cool. A clogged filter increases static pressure and starves the system of air across heat elements and coils. That lowers discharge temperature and often trips the high limit, which disables heat while the fan still runs. In hot, dry, dusty regions, filters load far faster, so this is a frequent source of cool air complaints.

Mechanical issues can mimic the same symptoms. A weak or obstructed blower wheel, failed capacitor, worn bearings, or a dirty or partially blocked indoor coil all reduce airflow and create uneven or cool supply air. Under today's DOE and SEER2 rules, indoor blower performance and external static pressure matter more, so the same airflow problems that cause safety trips also cut rated heating and cooling performance.

- Listen to the blower. If it sounds strong yet air is cold, heat strips, sequencing, or controls are likely at fault and require a professional.

- If airflow feels weak, check the filter first. Replace if loaded or gray.

- Look for visible dirt or icing on the indoor coil face if accessible.

- Confirm supply vents and returns are open and not blocked by furniture.

- Inspect visible ducts in attics or basements for kinks, crushes, or disconnections. Seal small accessible leaks with mastic or UL 181 foil tape. Leave major duct repairs to professionals.

Electrical Problems: Breakers, Fuses, Service Switches and Safety Precautions

Electric furnaces run on 240V power. Before any look beneath the panel, de-energize at the service switch and the breaker. Confirm the disconnect is on, dedicated breakers set, and check any cartridge or low voltage fuses without upsizing. You may reset a tripped breaker once. If it trips again, stop.

Never bypass safety devices like high limit switches or door interlocks, and do not use jump wires. Repeated breaker trips are a red stop light. Shut the system off if you notice burnt wiring, a burning smell, or scorching at lugs.

In our experience at Budget Heating (BudgetHeating.com), many electrical heat issues beyond a simple power reset involve components that require meters and training: heating elements, sequencers, contactors or relays, transformers, capacitors, and control boards. Leave diagnosis and replacement of these parts to a licensed technician. Electricity is unforgiving. Fix the problem without creating a new hazard.

Condensate, Safety Controls and When to Call a Professional

We often see electric heat disabled by condensate safety devices. When an air handler has a cooling coil, a clogged pan or drain lets water back up and a float or pan switch opens the heat circuit. The blower may keep running, so you feel cold air even though the heat strips are off. Think of the float switch like a lifeguard whistle for water problems, it stops play before damage spreads. Codes require proper traps, cleanouts, and overflow protection. If the drain is misinstalled or dirty, those safeties can trip and shut off heat by design.

Stop DIY troubleshooting and call a technician if you notice:

- Breakers that trip repeatedly.

- Burning smell, scorch marks, or melted insulation.

- Standing water near the air handler.

- The blower does not run on a heat call.

- Blower runs strongly but air never warms.

- Repeated high-limit trips or a persistent burning odor.

- Any suspected unsafe electrical issue.

These symptoms often point to failed heat strips, sequencers or contactors, or a control board fault that needs professional diagnostics.

Summary & Next Steps: Inspect, Reset, or Schedule Professional Service

Start with the basics: confirm thermostat mode and fan, swap batteries, make sure the service switch and breakers are on, install a clean filter, open registers, and check for condensate or visible duct issues. If heat still will not return, or you see water or electrical hazards, turn the unit off and schedule licensed service so a pro can safely test high voltage components. Electric furnaces still need care: replace filters every 1 to 3 months, keep returns clear, flush the drain seasonally, and book annual service. If you want a second set of eyes, our U.S.-based team has 30+ years in HVAC and can guide your next step.

- Get a Custom Quote

- Talk to Our Team by phone or chat

- Shop Electric Furnaces

- Shop Thermostats and Heat Strips

HVAC maintenance

HVAC maintenance

Cooling

Cooling Heating

Heating Learning Center

Learning Center Money Saving Tips

Money Saving Tips Product and Brands Insights

Product and Brands Insights Buying Guides

Buying Guides State by State

State by State HVAC Systems

HVAC Systems