HVAC Sizing Secrets: Why Choosing the Right Tonnage Matters

Selecting the right HVAC tonnage shapes three things that matter every day: comfort, energy bills, and equipment life. Get the size right and the system maintains even temperatures and steady humidity while using only the power it needs. Treat sizing like a design decision, not an afterthought.

In our experience, oversizing creates short cycles that feel like bursts of hot or cold air followed by swings and clammy rooms. It wastes energy, raises wear on components, and can shorten service life. Undersizing is the opposite problem: the unit runs and runs, struggles to reach setpoint, and still leaves some rooms uncomfortable.

Think of tonnage like choosing the right gear on a bicycle for a hill. The correct match keeps you moving smoothly and efficiently. The wrong gear has you either spinning out or grinding hard with little progress.

The path to proper sizing is straightforward: account for the home and climate conditions that drive the load, then match equipment capacity to that need. Working with a professional who performs a full calculation helps ensure balanced comfort, sensible runtimes, and a system that lasts.

Why Proper HVAC Sizing Matters: Comfort, Efficiency and Equipment Life

Right sizing is the foundation of a comfortable, efficient, long lasting system. In our field work, the pattern is clear: when capacity matches the real load, you get steady temperatures, proper humidity control, and quieter operation. Oversizing creates quick on and off cycles, which wastes energy at startup, leaves rooms clammy, and adds mechanical stress that shortens equipment life. Undersizing pushes the system to run constantly, raises utility costs, and still struggles to reach setpoint on peak days. Climate is the first driver, not a generic square foot per ton shortcut. Hot, humid regions need enough capacity plus meaningful moisture removal, so tonnage must be aligned to regional temperature and humidity. In milder or drier climates, a smaller, longer running system often delivers better efficiency and comfort. Get the size right and the payoffs show up every day: fewer temperature swings, lower energy use, and reduced wear on major components.

Common Sizing Mistakes: Myths to Avoid (Don't Rely on Square-Foot Rules)

Sizing an HVAC system is not about quick math or guessing. The most common pitfall is the square-foot rule, like 1 ton per X square feet. That shortcut ignores insulation levels, windows, orientation, air leakage and how the home is actually used. The other big myth is bigger is better. Oversized systems short cycle, create uneven temperatures, struggle to dehumidify and can wear out components faster, like wearing shoes two sizes too big.

- Replacing like-for-like without checking today's load after renovations or air sealing.

- Chasing higher SEER or a preferred brand while overlooking correct capacity.

- Ignoring duct condition and design, which can bottleneck an otherwise good system.

In our experience at Budget Heating (BudgetHeating.com), proper load calculations often point to smaller, not larger, equipment and deliver steadier comfort. Best practice is an ACCA Manual J room-by-room load calculation, then select equipment that matches the calculated load and confirm the ducts can move the required airflow. Avoid defaulting upward in capacity. A right-sized system runs balanced cycles, manages humidity and keeps bills in check.

Undersizing: How It Shows Up (Long Runs, Poor Peak Comfort) and Why It's Problematic

Undersizing shows up as marathon runtimes. On the hottest or coldest days the system runs almost nonstop, yet the thermostat lingers past the setpoint. Rooms feel flat during the afternoon peak, and indoor humidity can creep up because the equipment cannot remove latent load fast enough while it chases temperature. In our experience at Budget Heating (BudgetHeating.com), these are the systems that trigger the most complaints when heat waves hit.

Operationally, long runs at or near full output inflate utility cost and keep the compressor and blower under continual stress. Oversizing wastes energy through short cycling, undersizing wastes it through marathon runs. A correctly sized system matches capacity to the home's actual load, so it has reserve for spikes and stabilizes both temperature and moisture. With undersizing, comfort suffers first and energy use rises second, and extended full-throttle operation can pull forward repairs and replacement. Right sizing reduces unnecessary energy use and avoids that compounding stress over the life of the system.

SEER, SEER2 and Efficiency Rules: What to Know When Picking Capacity

SEER2 replaced SEER as the federal test method in 2023. Minimum SEER2 and EER2 now vary by U.S. region and by capacity, with distinct Northern, Southeast, and Southwest tiers. When you compare models, keep it apples to apples: SEER to SEER, SEER2 to SEER2.

Higher ratings can cut cooling energy, especially in hot climates, but only if sizing and installation are right. Oversized or undersized equipment short-cycles, runs inefficiently, and misses its label. In our field work, even modest oversizing can wipe out the gains. Think of a high-tech engine in the wrong size boat, the fuel savings vanish.

Oversizing: Causes, Symptoms and Long-Term Consequences

In our field experience, an oversized HVAC system shows up as short cycling. The unit reaches the thermostat setpoint quickly, shuts off, then fires back up again. Think stop and go traffic for machinery, it wastes energy and never settles into a steady, efficient rhythm. These brief cycles do not allow enough runtime for proper moisture removal, so rooms feel cool but clammy.

- Causes: Skipping a proper design, such as Manual J, S and D, and overlooking the building envelope and ductwork. Poor commissioning also leaves charge and airflow unverified.

- Symptoms: Frequent on and off cycles, weak humidity control, and higher than expected energy use during peak days.

- Long-term consequences: Extra starts and stops increase wear on compressors and blowers, raising the likelihood of repairs over time. Undersized systems have a different risk, they run near capacity for long periods, which also stresses components.

The fix is straightforward: a professional design using Manual J, S and D, attention to leakage and duct sizing, and proper commissioning to confirm refrigerant charge, airflow and static pressure. That combination keeps equipment reliable and comfort consistent.

The Right Way to Size an HVAC System: Manual J, Manual S and Manual D Explained

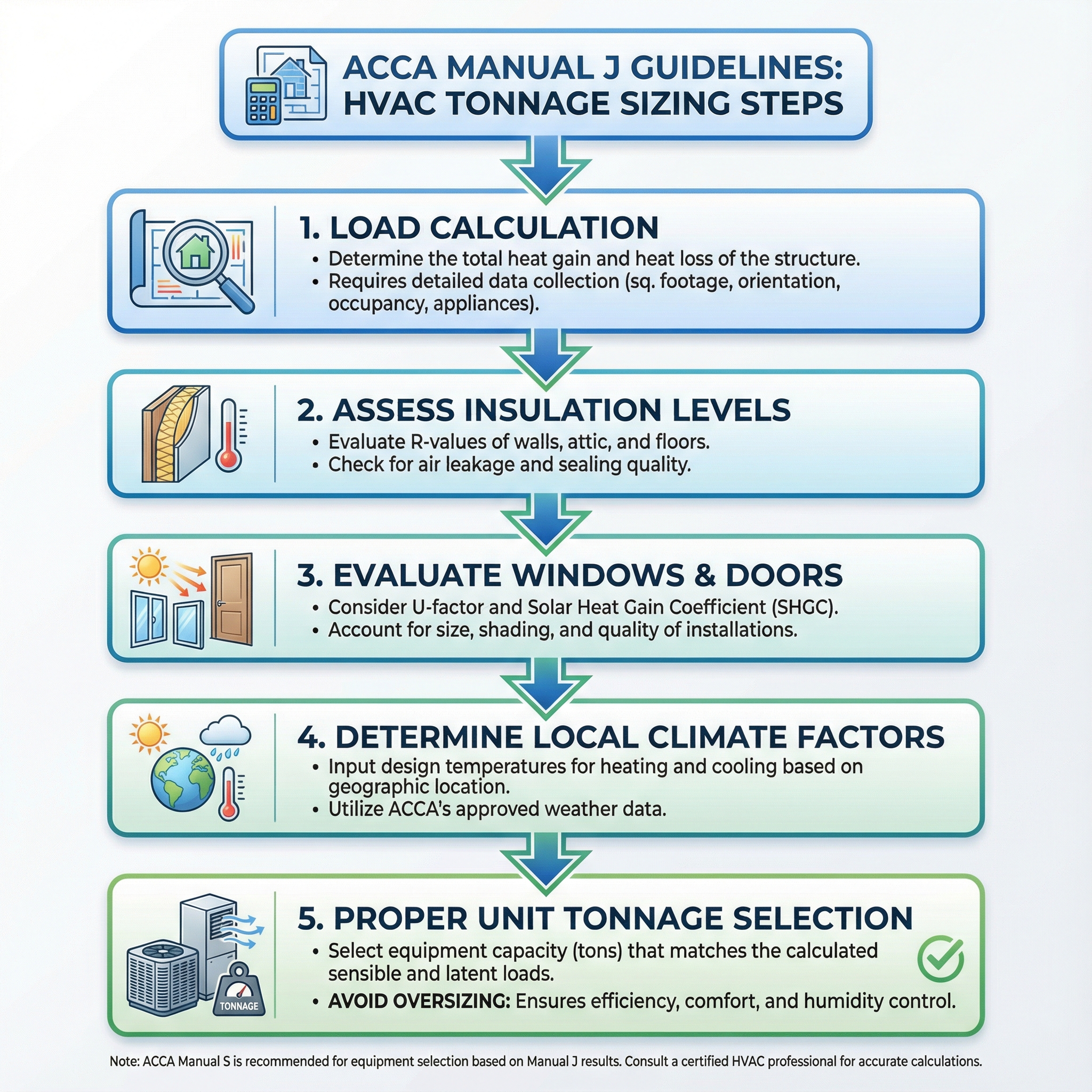

After 30+ years sizing systems, we start with ACCA Manual J. It is the room by room heat loss and heat gain calculation that accounts for your home's construction, insulation, windows, orientation, and occupancy. Think of it like tailoring a suit: measured for each room, not guessed for the whole house. Manual J should use your local design temperatures so the system runs steadily and avoids short cycling while maintaining comfort.

Next comes Manual S, which selects actual equipment to match the calculated loads. The chosen system must meet both sensible capacity, temperature control, and latent capacity, moisture removal. Performance varies with airflow and indoor and outdoor conditions, so target airflow is critical, commonly about 350 to 450 CFM per ton depending on climate and dehumidification needs. Always verify an AHRI matched combination so the outdoor unit, indoor coil, and blower are certified to work together.

Finally, Manual D verifies the duct system can deliver the required airflow to each room from the Manual J results. This includes correct supply and return sizing, acceptable total external static pressure, and reasonable duct velocities to keep noise in check.

- Gather data: conditioned area, ceiling heights, insulation, windows, occupancy, internal gains.

- Confirm climate zone and heating and cooling design temperatures.

- Insist on a room by room ACCA Manual J report.

- Request Manual S equipment selection with model numbers.

- Ask for a Manual D duct review or redesign if needed.

- Verify sensible and latent loads and target airflow, about 350 to 450 CFM per ton.

- Obtain AHRI matched system certification.

- Require commissioning checks: airflow, static pressure, temperature split, and humidity.

When Right-Sizing Still Fails: Tradeoffs, Limits and Better Alternatives

Right sizing is a strong start, but climate and regulation can force different choices. We lean on ACCA climate maps and local design conditions because national rules of thumb miss real-world behavior. DOE 2023 shifted ratings to SEER2 with region and capacity dependent minimums, so not every familiar model or approach fits every ZIP code.

- Hot, humid regions: A right-sized single stage system can hit the thermostat but leave indoor air sticky. Stronger latent control is needed. Better options include variable speed or two stage systems that run longer at low output, or a dedicated whole home dehumidifier.

- Dry climates with big day to night swings: Equipment sized for the peak can short cycle when loads drop, like tapping the brakes in stop and go traffic. Two stage or variable capacity units maintain steadier comfort without constant on off cycling.

- Regulatory constraints: In some regions and capacities, entry level models no longer meet SEER2 minimums. If the plan is a basic single stage replacement, that approach may be non compliant or less available. Stepping to a compliant higher efficiency model or a heat pump that meets the regional minimum is the cleaner path.

Avoid upsizing to chase comfort. Use local design data and pick equipment that matches both climate and code.

Quick Checklist: What to Ask, Inspect and Verify Before You Buy

Use this HVAC Sizing Secrets checklist at estimate time. We advise getting every promise in writing.

- Documents: room-by-room load calc with design temps, Manual J/S/D, AHRI certificate, proposal with model numbers, line set size, scope for ducts and electrical, permits, warranty.

- Commissioning: static pressure, CFM per ton, charge method with readings, supply and return temps, gas combustion test, heat rise, drain and leak checks.

- Questions: How was tonnage chosen, what duct fixes are included, who registers warranty, expected noise and efficiency, follow-up visit timing.

Next Steps: Get a Manual J, Verify the Design, and Insist on Commissioning

Get the sizing right with a documented Manual J, plus Manual S for equipment and Manual D for ducts. Oversizing short cycles and ruins humidity, undersizing runs too long and loses peak comfort. Verify ducts and airflow, size to realistic design loads with minimal oversize, then commission the system. Staged or variable capacity and zoning can steady comfort. We know you want this done once, the right way. With 30+ years in HVAC, our team can run the numbers and match the right kit.

- Get a Custom Quote

- Talk to Our Team by phone for U.S.-based support

- Shop Heat Pumps, Central AC, and Ductless Mini Splits

- Ask for commissioning and your Manual J/S/D printout