Introduction: Why Ionocaloric Cooling Could Reboot Heating & Cooling

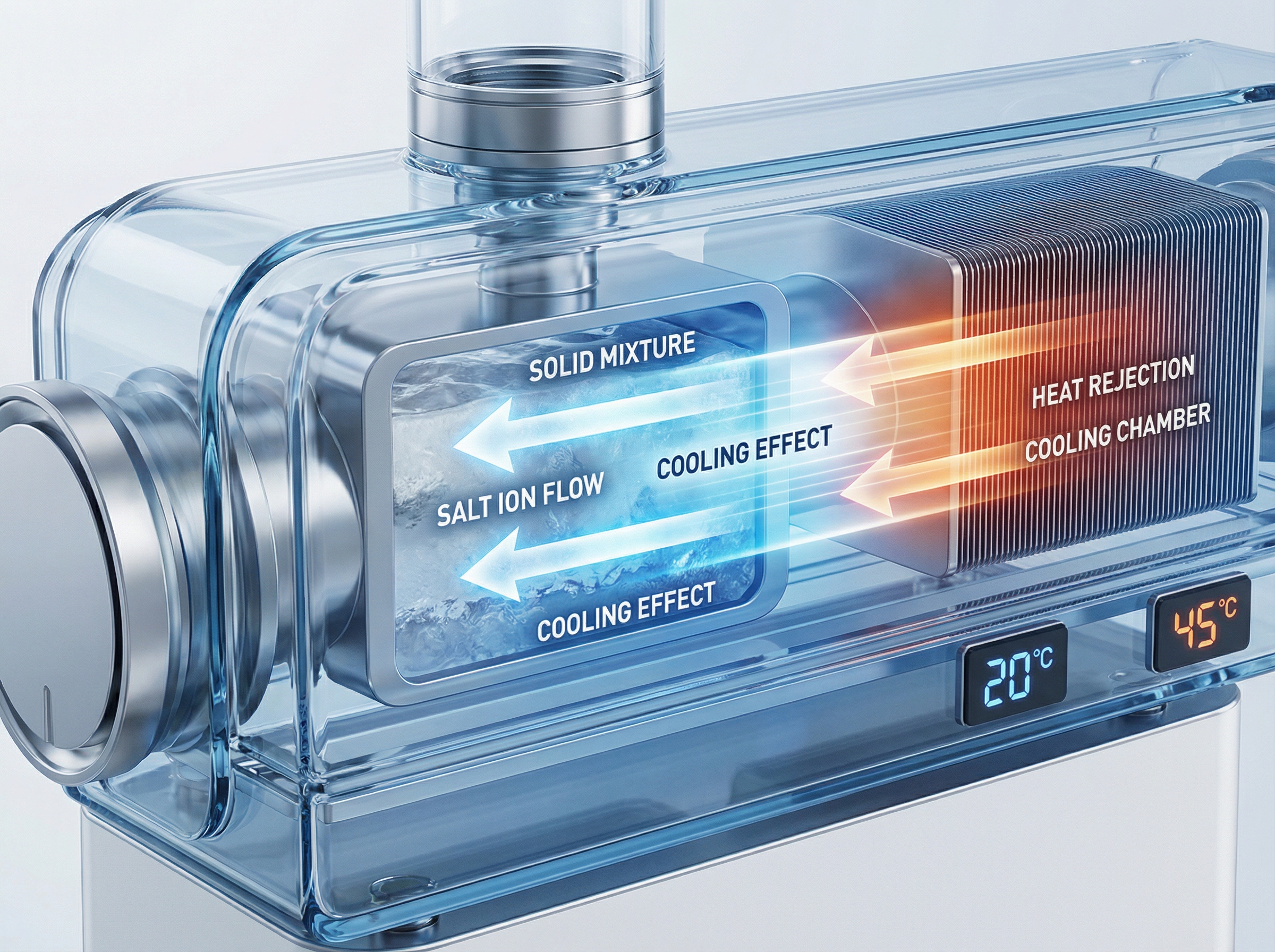

Heating and cooling shape daily comfort, energy bills, indoor air quality, and equipment longevity in homes. Today, most systems rely on combustion for heat or vapor compression for air conditioning, which use refrigerant gases with high global warming potential. Ionocaloric cooling is an emerging alternative that aims to move heat without those gases. It uses electrically driven ions from a salt to trigger a phase change, solid to liquid and back, in a working material. When the material melts it absorbs latent heat, when it solidifies it releases that heat, and ion flow acts like a dimmer switch that meters the effect in both directions.

Backed by U.S. Department of Energy research, the ionocaloric cycle points to cleaner, potentially more efficient, pumpable systems that can provide reversible heating and cooling in a single package. As the technology progresses from lab benches to pilots and commercial offerings, homeowners and professionals will be able to weigh how it affects comfort, energy costs, indoor air quality, maintenance needs, and long term system resilience. It is a fresh path that keeps the core goal the same, moving heat where and when it is needed.

What Is Ionocaloric Cooling? A Clear Definition

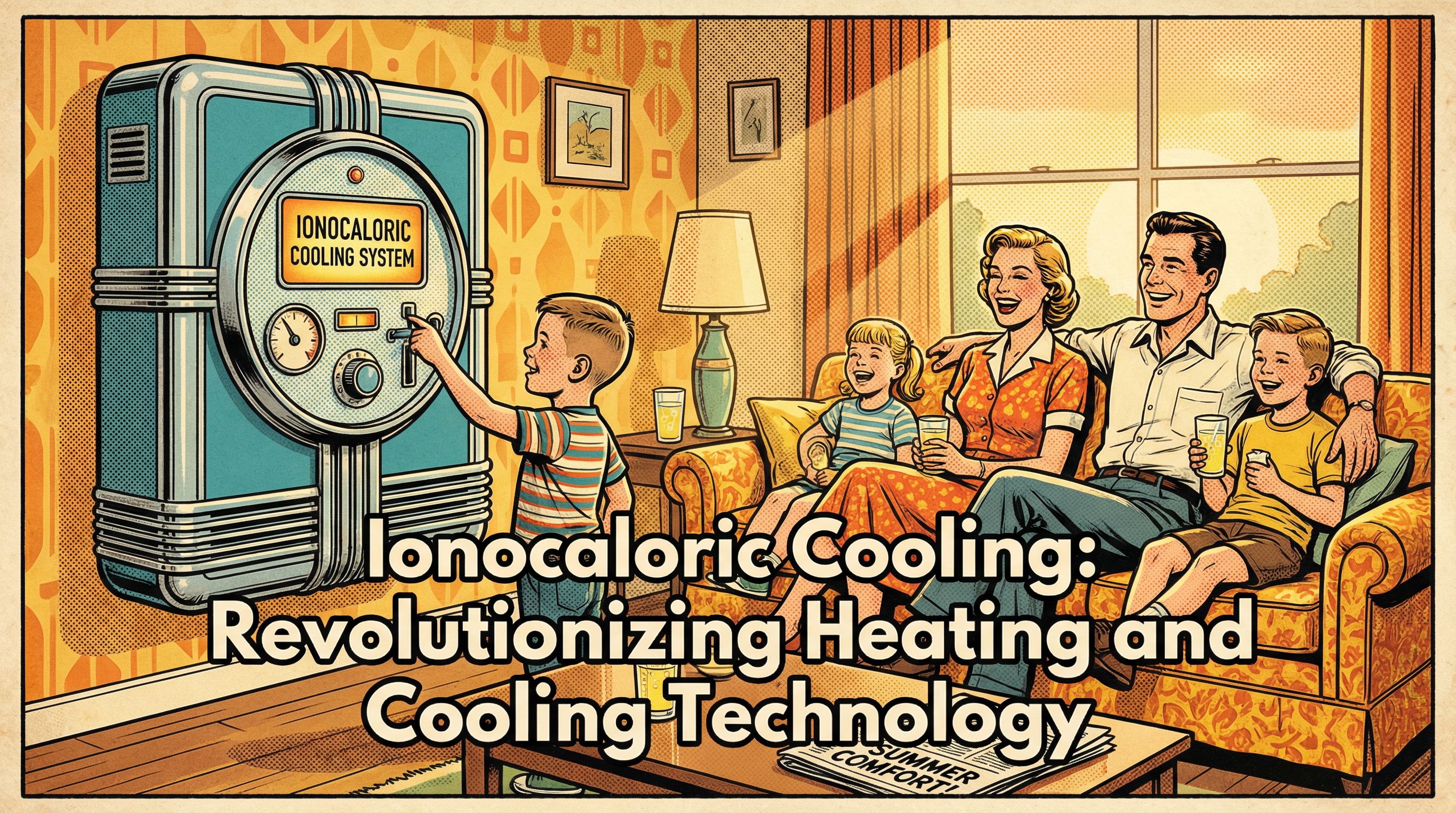

Ionocaloric cooling is a caloric effect in solid or soft materials that is triggered by changes in ionic configuration, distribution, or mobility under an external stimulus such as an electric field, chemical potential, pressure, or temperature. When ions migrate, intercalate, or change solvation state, the material's entropy shifts and the sample can heat or cool without using conventional vapor-compression refrigerants. In many systems, ion motion also nudges a phase change that taps latent heat, so a small ionic rearrangement can drive a much larger heat uptake or release, similar to flipping a switch that moves a big valve.

- Ion-conducting solids

- Hydrated salts

- Polymer electrolytes

- Ionic liquid based composites

The effect is related to electrocaloric, magnetocaloric, and barocaloric cooling, but is distinct in its ionic mechanism. Early lab studies and prototypes have shown measurable temperature and entropy changes and cyclic operation near room temperature, indicating potential for compact, refrigerant-free HVAC devices with high energy density.

Ionocaloric Cooling: Core Benefits and What It Means for HVAC

Ionocaloric cooling uses salt ions to drive reversible phase changes that move heat, targeting a single device that can both cool and heat. The cycle is reversible: directing ions one way promotes melting that absorbs heat, reversing the ion flow promotes solidifying that releases heat. In practice, the same unit can switch modes like a two way street for heat.

- Lower climate impact: Systems built on salts and phase change media avoid high GWP refrigerant gases, reducing leak risk and aligning with policies that cap or phase down HFCs, which helps future proof HVAC investments.

- Efficiency and operating cost potential: Leveraging latent heat with electrically driven ion transport targets higher seasonal efficiency than many vapor compression systems, which can translate to lower electricity use for the same load.

- Integrated, year round comfort and electrification: One device can provide both heating and cooling, supporting all electric building strategies and simplifying equipment choices.

- Practical heat transfer: Pumpable liquids enable effective coupling to air handlers, hydronic coils, and compact outdoor units.

- Safety and compliance: Reduced reliance on compressed greenhouse gases simplifies leak, code, and service concerns.

- Momentum: Development is supported by Berkeley Lab and UC Berkeley with U.S. Department of Energy funding.

Commercial timelines remain uncertain. In the meantime, prioritize high efficiency, low GWP heat pumps, improve insulation and air sealing, prepare electrical capacity, and track incentives that favor non HFC, high efficiency HVAC.

Safety, Maintenance and Practical Considerations for Owners and Technicians

Ionocaloric systems move heat by shifting a salt-based working fluid between solid and liquid states, removing high-pressure refrigerant risk. The loop is still sealed and paired with pumps, valves, sensors and power electronics, so apply the same safety discipline you would with any advanced HVAC.

- Homeowner tasks: shut off at the thermostat and open the disconnect before cleaning; keep indoor and outdoor sections clear for airflow; replace or clean return filters and gently vacuum grilles; verify condensate drains are clear and, if allowed by the manufacturer, flush with mild vinegar; use the app or controls to apply approved firmware updates, review alerts and listen for new noises or vibration; after storms clear debris; if you see oily film, crystalline residue or solvent-like odors, power down, ventilate and avoid contact.

- Call a licensed pro for: installation or any sealed-loop work; electrical issues; seized or noisy pumps or fans; error codes or sensor faults; any leak or spill; corrosion or moisture in the loop; integrations with furnaces, resistance heat, solar or batteries. In our experience at Budget Heating (BudgetHeating.com), these visits keep minor issues from turning into downtime.

- Safety cautions: do not open the loop; avoid chemical contact; beware very hot or cold surfaces; capacitors can retain charge; ventilate any solvent leak; wear basic PPE and keep CO detectors functional if combustion appliances are present.

- Maintenance cadence: monthly to quarterly homeowner checks; annual professional inspection, cleaning and calibration; professional inspection after surges, flooding or suspected leaks.

Comparing Ionocaloric with Magnetocaloric, Electrocaloric and Thermoelectric Cooling

From a practical standpoint, the caloric family differs mainly in the trigger that drives heat pumping. Ionocaloric uses ions to tune a material's phase behavior, magnetocaloric uses magnetic fields, electrocaloric uses electric fields, and thermoelectric moves heat with charge carriers. Ionocaloric targets larger temperature lifts with common materials and limited rare earths, a path that could fit space conditioning. There are no SEER or SEER2 ratings for ionocaloric yet, since no certified seasonal test exists, so efficiency comparisons to today's ACs remain qualitative.

- Magnetocaloric: strong magnets, precise control, cost and weight hurdles.

- Electrocaloric: thin films, high voltage, best for compact electronics and modest loads.

- Thermoelectric: simple and solid state, best for spot or sub ambient cooling, lower efficiency at scale.

- Ionocaloric: if materials and cycles mature, a candidate for refrigerant free air or hydronic coils.

Limitations, Misconceptions and When Ionocaloric Isn't the Right Choice

Misconceptions to correct: it is not a drop-in refrigerant swap; hardware uses a solid-liquid working pair and ions, which avoids high-GWP refrigerant leaks. It does not give free cooling; power is required to move heat and run pumps and controls. It is reversible for heating as well as cooling. It is not limited to near-freezing like road salt on ice; materials are engineered for HVAC ranges. It is not on the market yet, so no SEER or SEER2 labels. And new tech does not erase maintenance: proper sizing, commissioning, filter and heat exchanger cleaning still matter.

Where it may not be the right choice today:

- You need a proven, code-listed, AHRI-rated system for permits, rebates, or utility programs today. Alternatives: inverter mini splits, central heat pumps, or high-efficiency gas furnaces with AC coils.

- Mission-critical uptime or remote serviceability is paramount. Alternatives: standard VRF, packaged rooftop units, or hydronic chillers with established parts pipelines.

- Extreme climates requiring validated cold-climate performance. Alternatives: cold-climate air-source heat pumps or geothermal systems with documented low-ambient capacity.

Buying and Preparing for Ionocaloric Systems: A Homeowner & Installer Checklist

- Availability and certs: confirm commercial status, capacities, UL/ETL, AHRI, local acceptance.

- Fit and design: ducted, ductless, or hydronic; require Manual J/S and Manual D.

- Performance: EER/SEER, COP/HSPF, 47°F and 17°F heat, turndown. In our experience at Budget Heating (BudgetHeating.com), set targets and commissioning early.

- Electrical: voltage, MCA and breaker, panel space, soft start, demand response.

- Materials and install: ionic fluids and PCM, SDS, toxicity, corrosion, cleanup; footprint, condensate, noise.

- Controls and integration: thermostat type, zoning, PV or batteries, auxiliary heat, thermal storage.

- Service, cost, climate, commissioning: tasks, local support, warranty; itemized quotes, kWh, incentives; cold limits, freeze protection, generator; verify airflow, pump flow, temps, safeties, get a report with O&M; if not available, air seal, balance ducts, plan panel, pick a swappable low GWP heat pump.

Path to Commercialization: Prototypes, Manufacturing and Cost Drivers

Moving from lab proof to a marketable unit takes more than a clever prototype. It means building repeatability, safety, and installability into the design. In our experience, successful teams run small pilot builds, then field trials across different loads to expose weak spots early. Manufacturing must lock specifications, design for manufacturability, and create end of line tests.

Key cost drivers include materials, electronics, labor, tooling and fixtures amortized over volume, production yield, warranty reserves, packaging, and freight. Precise cost and savings ranges are not available. To exit the lab, the product also needs third party safety and performance validation, service documentation, installer training materials, spare parts planning, and serial tracking. When those boxes are checked, units install cleanly, start up predictably, and can be serviced with standard tools.

Energy, Emissions and the Regulatory Context for Ionocaloric Technologies

Ionocaloric cooling aligns with HFC phase‑downs, but market entry will be driven by refrigerant rules, efficiency thresholds, and safety codes. In the United States, the EPA AIM Act limits high‑GWP HFCs in new residential and light‑commercial AC and heat pumps starting in 2025, with limited sell‑through into 2026. California caps GWP at 750 for new AC from 2025, and several states are following. Although ionocaloric systems use salts and phase‑change media, products still need UL or ETL listing, compliance with ASHRAE 15 and 34, UL 60335‑2‑40, local mechanical and electrical codes, and environmental and toxicity review of any new electrolytes. DOE efficiency rules now use SEER2, EER2, and HSPF2 with regional minimums, roughly 13.4 SEER2 in the North and about 14.3 SEER2 in the Southeast and Southwest, plus EER2 in the Southwest. Heat pumps must meet about 14.3 SEER2 and 7.5 HSPF2. Until ionocaloric test methods exist, manufacturers must rate under DOE procedures or approved alternatives. In the EU, accelerated F‑gas phase‑downs, Ecodesign, and Energy Labelling favor non‑HFC options, but require conformity assessment and recognized performance ratings.

Conclusions and Next Steps: Research, Policy and Industry Actions

Ionocaloric cooling offers a credible path to efficient heating and refrigeration without high GWP gases, potentially enabling compact systems that, if they reach premium SEER2-tier performance, cut electricity use and bills while reducing climate impact. Realistically it is still early to mid research, so the near term is about materials with large reversible entropy changes at practical temperatures, balancing ionic conductivity with electrical and chemical stability, engineering robust heat exchangers and interfaces, proving long-cycle durability at scale, and creating SEER2-equivalent metrics plus safety and code frameworks; next steps are clear: researchers should prototype at building scale and publish standardized results, policy makers should align test methods and approvals, investors should back pilots and manufacturing readiness, and homeowners can plan for low GWP options and choose today's best high efficiency heat pumps while tracking progress, and our team can help map that path.

- Get a Custom Quote for a high efficiency heat pump or AC sized to your home.

- Talk to Our Team by phone for straight answers on equipment, efficiency tiers and code-ready options.

- Shop Heat Pumps at wholesale pricing from leading brands.

- Ask us to notify you as ionocaloric prototypes move toward field trials.