How Central Air Conditioning Works: a quick, practical primer

Central air conditioning is the backbone of whole home comfort: it pulls heat and humidity from indoor air, sends that heat outside, and recirculates cooled, filtered air through your ducts to keep temperatures even from room to room. A typical central air split system places the evaporator coil and blower inside (often with a furnace or air handler) and the compressor and condenser coil outside. The two halves connect with refrigerant lines and are managed by a thermostat.

At the heart is the vapor compression refrigeration cycle. Think of the refrigerant as a heat sponge: it absorbs heat at the indoor coil while boiling at low pressure, the compressor squeezes it to a hot, high pressure state, the outdoor coil releases that heat to the outside air, then an expansion device drops the pressure so the cycle can repeat. Understanding major components and the refrigeration cycle helps homeowners translate specs like SEER2 into real world comfort, costs, and maintenance decisions.

Quick overview: what a central air system looks like in your home

Most central air systems in houses are split systems. Outside, a metal cabinet sits on a pad, containing the compressor, condenser coil, and a fan. Indoors, there is an air handler or a furnace with an evaporator coil in the plenum, plus a blower that moves air. The blower pulls warm air from rooms through return ductwork, cools it across the coil, then sends it back through supply ducts. Two copper refrigerant lines connect the indoor and outdoor sections. A wall thermostat coordinates the two, starting and stopping cooling as needed. Picture it like a relay team: the outdoor unit dumps heat, the indoor side moves cooled air through the ducts.

Core components of a central air conditioner (what each piece does)

Your central AC is a relay team, each part moving heat out of the house. Here is what to look for and what it does. In our experience at Budget Heating (BudgetHeating.com), customers who can name these parts make faster, clearer decisions.

- Outdoor condenser unit (compressor, condenser coil, fan): dumps heat outdoors.

- Indoor evaporator coil (in the air handler or furnace plenum): pulls heat from indoor air.

- Blower: circulates air through the ductwork.

- Refrigerant lines: copper pair linking indoor and outdoor units.

- Expansion device: readies refrigerant for the evaporator.

- Thermostat and controls: command temperature and coordinate operation.

- Duct network: supply and return paths with grilles that deliver and pull air.

To map your system, find the outdoor condenser, the air handler or furnace cabinet, and your main supply and return grilles. Once you can spot these, the rest of the layout clicks into place.

Air filtration and indoor air quality: how filters, coils and runtime affect comfort

Filtration affects the air you breathe and how the system runs. Common residential filters are MERV 8 to 13. Higher MERV catches more dust and some allergens, but raises pressure drop, so match the filter to the blower because airflow is critical. An overly tight filter can cut capacity or even let the evaporator coil ice. Check and change filters every 1 to 3 months based on pets, dust, and usage. Dirty filters and coils force longer runtime and uneven temps, while clean coils transfer heat and remove moisture efficiently. Optional IAQ upgrades include deeper media filters, UV lights to keep the coil cleaner, and whole-home dehumidifiers for high humidity or allergy concerns. In three decades of field work, clean filtration reliably shortens runtime and steadies comfort.

Routine maintenance checklist: keep your central AC efficient and reliable

Regular attention keeps central AC efficient and typically extends service life to 15 to 20 years. Use this checklist for safe homeowner tasks and leave higher risk work to a professional.

Homeowner checklist:

- Replace or wash the air filter every 1 to 3 months.

- Maintain at least 2 feet of clearance around the outdoor unit.

- Shut power off, then gently rinse the outdoor coil with a garden hose, not high pressure.

- Keep all supply and return grilles open and unobstructed.

- Check for steady condensate drainage during cooling season.

Airflow and duct care:

- Have ducts inspected, sealed, and insulated, and ensure adequate return paths.

- Target roughly 350 to 450 CFM per ton, lower end in humid climates, and keep static pressure within manufacturer specifications. Poor airflow is like breathing through a straw, it stresses components and hurts comfort.

Professional only:

- Electrical diagnostics and repairs, refrigerant charging or leak repair, major component replacement, and any work on systems that share combustion appliances. Refrigerant handling is regulated, and improper work is unsafe and illegal.

- Annual tune ups that verify airflow and static pressure, deep coil cleaning, and clearing slow or clogged condensate drains.

Annual professional inspections, plus the simple tasks above, keep efficiency high and reduce failures.

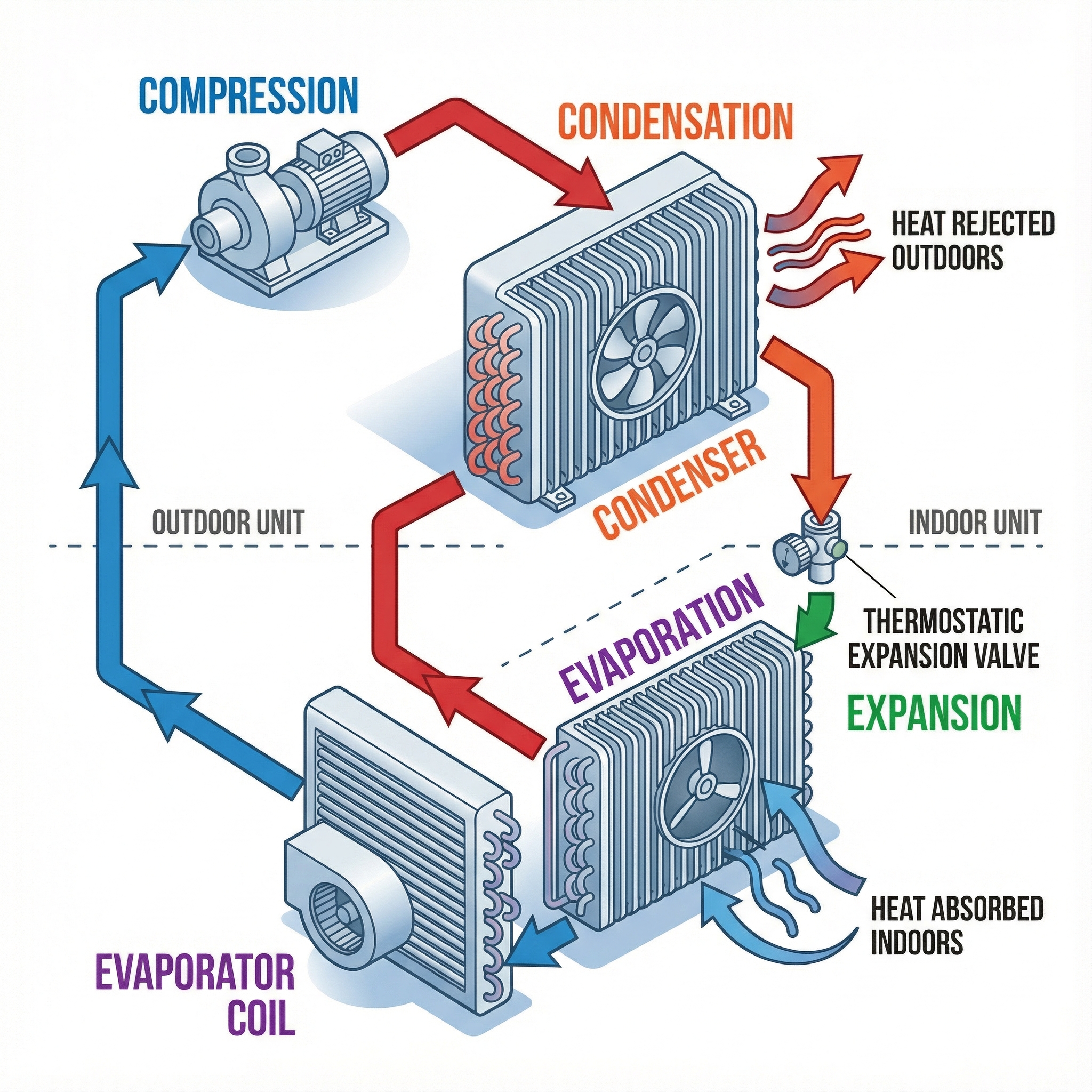

Step by step: the refrigeration cycle that actually cools your home

When your thermostat calls for cooling, it signals the system to start the vapor compression cycle. Here is what happens in order, every single time:

- Compressor: It takes low pressure refrigerant vapor and squeezes it, raising its pressure and temperature.

- Condenser: That hot vapor moves to the outdoor coil. The condenser fan pushes outdoor air across the coil, the refrigerant releases heat to the outside, and it condenses into a high pressure liquid.

- Expansion device: The liquid passes through a TXV, fixed orifice, or capillary tube that drops its pressure and temperature.

- Evaporator: Cold, low pressure refrigerant enters the indoor coil. The indoor blower pulls warm, humid air across it. The refrigerant evaporates, absorbing heat and moisture from your air.

- Return to compressor: The refrigerant vapor heads back to the compressor and repeats this loop until the thermostat setpoint is met.

Think of the evaporator coil like a sponge for heat and moisture. Once the thermostat is satisfied, the system stops.

Thermostats are simple on or off commands. Lowering the setpoint does not cool faster, it only tells the system to run longer. Single stage compressors operate at full output whenever they are on. Two stage and variable speed compressors modulate capacity for steadier temperatures and stronger humidity control. In our experience at Budget Heating (BudgetHeating.com), variable speed systems often run gentle, longer cycles that keep rooms even and dry, which feels cooler at a higher setpoint.

Match the compressor type to your comfort goals: single stage for basic cooling, two stage for improved balance, and variable speed for the most consistent comfort and dehumidification.

Efficiency and SEER/SEER2: what the numbers mean for your energy bill

SEER is the seasonal energy efficiency ratio, how much cooling you get per unit of electricity over a typical season. Think of it like miles per gallon for air conditioning. SEER2, introduced in 2023, uses tougher, more realistic test conditions that include higher external static pressure from ducts and fan power. The same unit often shows a lower SEER2 number than its legacy SEER. In our experience, that drop is expected because the yardstick changed, not the equipment.

Energy use scales roughly inverse to SEER. Replace a SEER 10 unit with SEER 13 and cooling energy typically falls about 23 percent. Step up from SEER 10 to SEER 16 and you are near 38 percent. Actual dollar savings depend on climate, hours of use, local kWh rates, duct condition, and installation quality. SEER sets the efficiency potential, your home and setup determine how close you get to it.

Performance bands in the market: many older systems are SEER 8 to 10. Modern code minimums cluster around 14 to 15 SEER, roughly 13.4 to 14.3 in SEER2, with regional minimums enforced under SEER2. High efficiency residential equipment reaches legacy SEER 18 to 22 plus, which converts to mid to high teens in SEER2. Higher ratings usually pair with two stage or variable speed compressors, ECM blowers, and smarter controls that also improve humidity control and comfort.

Central air vs. other cooling options: clear tradeoffs and when to pick something else

Central air delivers whole home comfort, but it is not always the best fit. Very small spaces, mild climates with few cooling hours, or homes without ducts often see lower upfront cost with other options. In very cold regions, if heating drives the decision, pair a gas furnace or a cold climate heat pump with backup heat.

- Small rooms or studios: pick a high efficiency window unit or a quality portable.

- No ducts or mixed use areas: a ductless mini split targets zones and avoids duct losses.

- Cooling only a few rooms: a mini split or modern window unit keeps costs contained.

From years in the field, we see these myths trip people up: lowering the thermostat will not speed cooling; bigger is not better and oversizing cuts dehumidification; closing vents wastes energy; refrigerant is not a routine top off; maintenance matters; SEER alone does not guarantee savings. Sizing by Manual J is key.

Choosing a system, brand and understanding costs: installation, savings and red flags

In our field experience, compare brands by efficiency, features, warranty support and parts access, then judge lifetime cost, not just price. Moving from SEER 10 to 13 cuts cooling energy about 23 percent, to 16 about 38 percent. Payback hinges on climate, kWh rate, run hours, duct condition and install quality. Elevation and urban heat islands affect sizing.

- Gather home data: square footage, insulation, windows, shading and problem rooms.

- Require Manual J, Manual S and Manual D for load, equipment and ducts.

- Verify AHRI match, SEER2 or EER2, targeted CFM per ton and a humidity plan.

- Correct line set sizing with nitrogen purged brazing.

- Deep vacuum to 500 microns, proven tight.

- Charge by weight plus subcooling or superheat.

- Trapped condensate, level pad and clearances, electrical permits and disconnects, documented commissioning including airflow and delta T.

- Ask for AHRI certificates, model numbers, duct leakage testing, warranties and permits.

- Red flags: sizing by square footage, no load or duct testing, vague quotes without permits or model numbers.

Keep it efficient: summary, upgrade signals and next steps

Getting rated efficiency comes from right sizing, tight ducts, verified installation and regular maintenance. Modern single-stage, two-stage and variable-speed systems in the mid to high teens SEER2 modulate better, control humidity and cut bills. If your system is 15 to 20 years old, noisy, needs repeat repairs, struggles with humidity or trails current SEER2, it is time to plan a replacement. Not sure where you stand? Book a tune up with a trusted HVAC pro or lean on our 30+ years of experience for a clear, no-pressure plan.

- Get a Custom Quote

- Talk to Our Team (U.S.-based phone support)

- Shop Heat Pumps, AC Systems and Ductless Mini Splits

- Ask about wholesale pricing, free shipping on many systems and Affirm