Why Zoned HVAC Solves Multi Story Townhome Comfort Problems

In multi story townhomes the pain is predictable. Upper floors run hot in summer, lower floors feel cool in winter, and a single hallway thermostat tries to average it all. One control point cannot satisfy bedrooms, living space, and stairwells at the same time, so comfort drifts and the system short cycles or overworks.

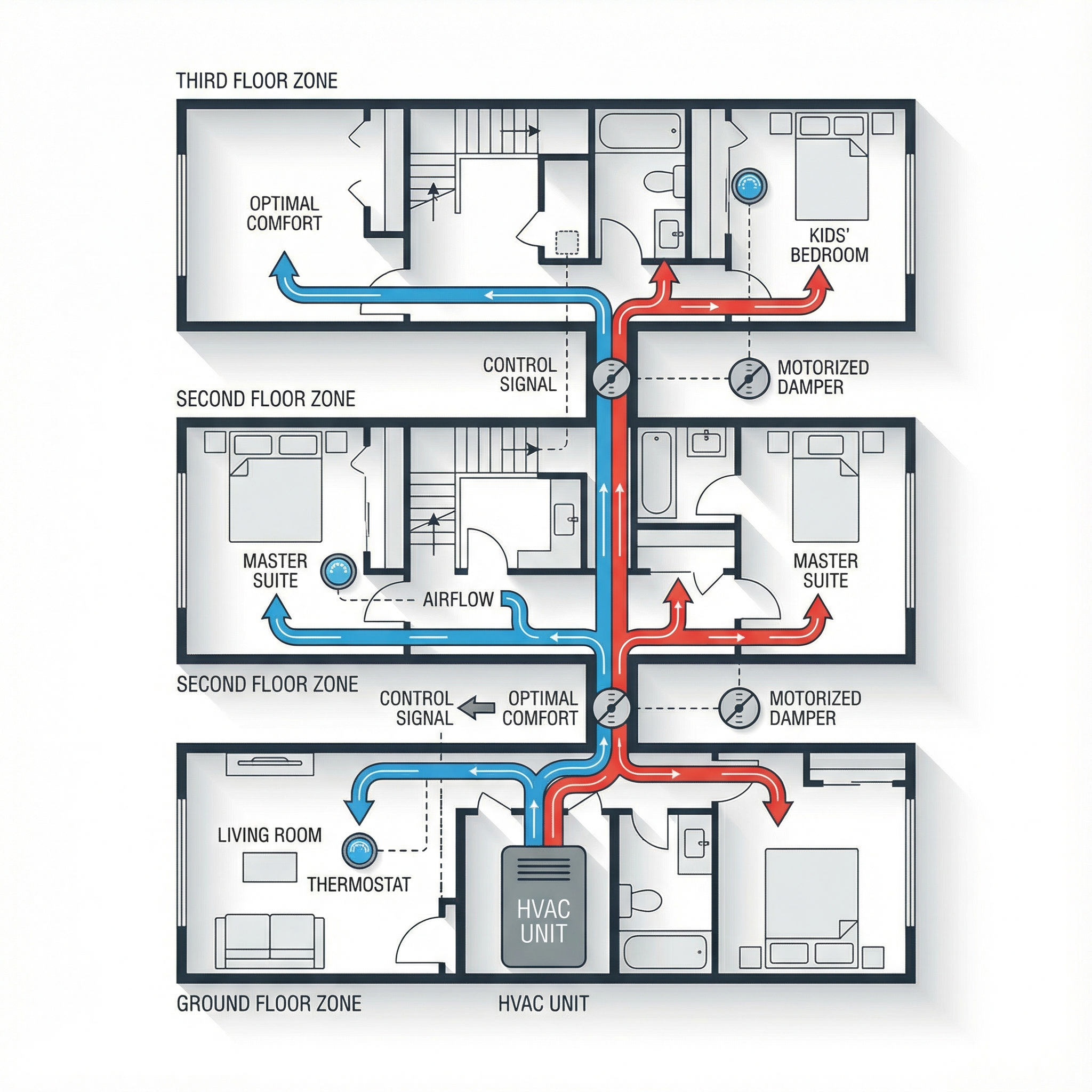

Zoned HVAC fixes that by dividing the home into independently controlled areas, sending heating and cooling only where it is needed. This is done with motorized dampers in the ductwork paired with multiple thermostats, or by using separate systems for each zone. Think of it like having light switches for each room instead of one master switch for the whole house. Each floor gets the temperature it needs without starving or overfeeding the others.

In this guide you will see how zoning works, why stacked floor plans benefit, the key design and equipment choices, wiring and controls basics, what changes between retrofit and new construction, what to expect for costs and commissioning, and the maintenance essentials that keep a zoned system performing as designed.

How Zoned HVAC Works: Dampers, Thermostats, and System Architectures

From years of installs, zoning uses motorized dampers, like valves in plumbing, to modulate trunk or branch airflow so the calling thermostat gets air. A zone control panel reads thermostats or sensors and drives damper actuators and equipment relays to keep flow balanced.

- One central air handler with dampers creating multiple zones.

- Several smaller systems, one per floor.

- Ductless multi split or VRF for room control.

Core parts: zone thermostats or sensors, a control panel, damper actuators, and the dampers. When sized and sequenced well, airflow stays stable and comfort stays even.

Benefits of Zoning: Comfort, Energy Savings and Happier Occupants

Zoning balances temperatures between floors by giving each level its own thermostat and controlled airflow. Independent schedules let bedrooms run cooler at night and living areas warmer by day. Targeting energy only to occupied zones cuts wasted runtime and cycling, reducing strain on major components and often extending equipment life.

Savings are real. Field results show most homes benefit, with about 70% using less energy and about 90% reporting better comfort. In multi story townhomes, low double digit reductions are common, and modeled comparisons show roughly 6% versus a single zone. In our experience at Budget Heating (BudgetHeating.com), zoning pairs best with variable speed or modulating equipment that runs at low capacity when only part of the house calls. Typical layouts use one zone per floor, plus extras for large open or sun soaked rooms.

Design Considerations Unique to Multi Story Townhomes

Townhomes are unforgiving of sloppy HVAC design. We start with a room-by-room Manual J at local design temps, then match equipment by Manual S and size ducts by Manual D so each floor actually receives the airflow it needs.

- Zones: begin with one per floor, then add zones for sun-heavy rooms, kitchens, wings, or bonus spaces that see different use patterns.

- Ducts and dampers: preserve airflow and acceptable static pressure in every operating mode. Avoid undersized ducts or too many small zones that drive static too high.

- Supply and return paths: each zone needs a dedicated return or transfer path. Closed bedroom doors without returns cause pressure imbalances and poor comfort.

- Thermostats: mount on interior walls away from sun, stairwells, kitchens, and supply registers. Use remote or averaging sensors for large or irregular zones.

- IAQ and ventilation: integrate ERV or HRV and local exhaust so fresh air delivery stays consistent under different zone configurations.

- Noise: high air velocity and fast dampers create noise. Use correct duct sizing, lined trunks, slow-acting dampers, and variable-speed blowers to keep bedrooms quiet.

Regional, Code and Refrigerant Issues That Affect Zoning Choices

Zoned townhomes are shaped by climate and code, not just equipment. Many jurisdictions expect designs aligned with ACCA Manuals J, S, and D, and some reference Manual Zr for zoning acceptance. Efficiency compliance is set by SEER2, EER2, and HSPF2 minimums, and zoning does not change those thresholds.

- Cold regions: size for heating load and keep interzone setpoints realistic.

- Hot humid: emphasize moisture control with long, low capacity run time.

- Mild: zone to manage solar gain and occupancy patterns.

The AIM Act is moving systems from R 410A to A2L refrigerants like R 32 or R 454B. Designs must follow local adoption, allowable refrigerant charge per room, and any required leak detection or other code provisions.

Wiring, Zone Controls, Relays and Advanced Temperature Strategies

Zoning starts with clean wiring to the zone control panel. Each thermostat lands there, so calls are clear. The panel sequences dampers, enforces a minimum open, and signals the air handler to prevent short cycling. Its relays drive actuators and interlock indoor and outdoor units, so match control voltages and relay ratings. We follow diagrams and verify with a meter.

Direct digital control lets us stage or modulate capacity, set minimum runtime, coordinate variable capacity equipment, and add logic like zone priority, temperature spread limits, and anti-opposition to stop zones from fighting.

Watch static pressure. Too much bypass can overcool coils, cut dehumidification, and waste energy. Favor ECM blower control, planned return paths, and designed relief, not ad hoc bypass.

Tradeoffs & Common Mistakes: When Zoning Is NOT the Best Choice

- Relying on bypass dampers for pressure control can over cool coils and weaken dehumidification; prefer designed return paths, ECM blower pressure control, and minimum zone sizes.

- Closing supply vents to save energy is a myth. It raises static pressure, increases duct leakage, and can cause coil freeze, noise, and wear.

- Many tiny zones on a single stage, oversized system short cycle and raise humidity; use variable capacity equipment or consolidate zones.

- Consumer smart vents are not integrated zoning. Ad hoc vent closures can overpressurize ducts and damage equipment.

- Other errors: thermostats in sun or stairwells, skipping air sealing, and assuming high SEER alone will fix comfort.

Not ideal fits: extremely cold climates, consider cold climate heat pumps per zone, hybrid heat, or per floor systems; small tight one level homes, favor a right sized single zone and envelope upgrades; retrofits with inaccessible ducts, use ductless mini splits or per floor systems.

Choosing Equipment: Variable Speed Blowers, Heat Pumps, Ductless and VRF Options

Zoned townhomes work best with equipment that can throttle. Variable speed blowers and modulating heat pumps are like a dimmer switch, matching part load so temperatures and humidity stay steady. SEER and SEER2 both measure seasonal cooling efficiency, but SEER2 uses a stricter, more real world test, so numbers are lower than legacy SEER. Many townhome systems land in the mid to high teens SEER2. Premium variable speed units rate higher and cut cooling kWh as SEER2 rises. In cold climates, size each zone's heat to about 125% of its design load to recover from setbacks without oversizing. In our experience at Budget Heating (BudgetHeating.com), pairing zoning with wide modulation avoids short cycling.

- Ductless mini split or VRF: best for retrofits, limited duct access, and per floor independent control.

- Ducted: keep sound trunks for hidden distribution, using variable speed air handlers for quiet, balanced airflow.

Installation Checklist & Maintenance: Permits, Commissioning and Ongoing Care

Upfront planning: gather house details (room areas, window sizes and orientation, insulation levels, occupancy patterns). Confirm permit requirements and plan electrical circuit sizing and a safe condensate path. In retrofits we often favor ductless or per-floor systems to avoid major duct changes; new construction is the best time for integrated ducted zoning or VRF with clean routing.

- Prestart checks: verify permits on site, breaker space, drain slope, and thermostat locations.

- Commissioning, like tuning an instrument: confirm room-by-room airflow and balancing, damper operation and sequencing, static pressure inside manufacturer limits, temperature split under load, and thermostat calibration.

- Cost planning: adding a two-zone forced-air system typically adds about $2,000 to $3,500. A third zone or complex ductwork increases cost. Utility or state rebates can offset installation.

Ongoing care: homeowners should check or replace filters every 1 to 3 months, keep grilles and outdoor units clear, and monitor condensate drains. Pros should perform annual tune-ups, or twice yearly for heat pumps, to inspect dampers, measure static pressure, verify refrigerant, clean coils, and test controls. Call a licensed HVAC professional for refrigerant issues, electrical faults, combustion or CO concerns, damper or control problems, and any wiring or ductwork changes.

Next Steps: Is Zoned HVAC Right for Your Townhome?

Zoned HVAC fixes per floor hot and cold spots and cuts waste when it is designed and maintained correctly. That means proper load calculations, right sized equipment, smart duct and damper layout, and thorough commissioning. In a townhome, the choice is about comfort, energy costs, and timing. Plan it early for long term comfort and control. With 30+ years and 200,000+ orders, we can help you get it right.

- Get a Custom Quote: share your layout and priorities, receive a zoning plan and matched equipment list.

- Talk to Our Team: U.S.-based techs for straight phone support and practical guidance.

- Shop Zone Controls and Ducted Systems: wholesale pricing, factory warranties, and Affirm financing.