Why HVAC Noise Matters: What Your System Is Trying to Tell You

HVAC noises, whether rattling, banging, whistling, hissing, or a persistent hum, are usually early warnings, not harmless quirks. From hands-on service experience, the sound is often the first clue, like a smoke alarm chirp that tells you a battery is low before the alarm fails.

Noisy operation typically signals underlying issues: airflow restrictions, duct leaks, loose hardware, or failing motors and bearings. Left alone, these problems can reduce comfort, raise energy bills, and shorten equipment life.

This article will help you match common sounds to likely causes, try safe homeowner checks, understand the limits of DIY, and know when a licensed technician is appropriate. Begin with simple, safe steps: verify a clean filter, confirm supply and return vents are open, snug any loose access panels, and clear debris around the outdoor unit. If you hear metal-on-metal scraping, a sharp electrical pop, or notice a burning odor, cut power and stop troubleshooting. A steady hiss at the indoor coil or line set may indicate a refrigerant leak, which requires certified service.

Quick safety checklist: Is that HVAC noise an emergency?

Before any troubleshooting, prioritize safety:

- Shut it down for: loud clanking or banging, metal-on-metal grinding, electrical buzzing with breaker trips or burning smells, refrigerant hissing plus weak cooling, or any gas odor or smoke.

- You may reset a tripped breaker once; if it trips again, stop and leave it off.

- Before touching panels, turn the system OFF at the thermostat and at the breaker.

- Document where, when, and what you hear: air handler, outdoor unit, or ducts; startup, running, or shutdown; rattle, buzz, squeal, hiss, or pop.

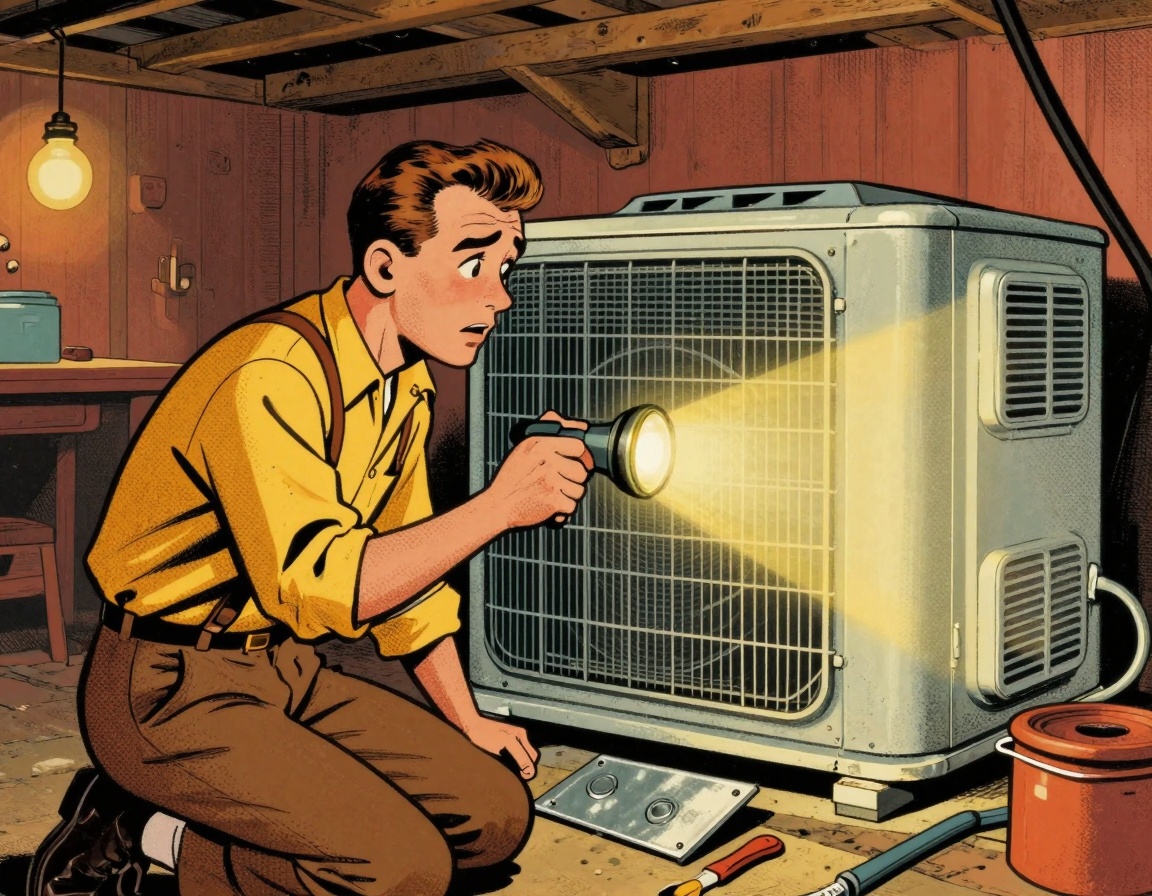

How to identify the sound: Match the noise to the likely problem

- Whistling or whooshing: restriction or high velocity from a dirty filter or coil, blocked or small returns, nearly closed registers, leaky or undersized ducts.

- Banging or thumping: loose parts, out-of-balance blower, or ducts flexing from pressure swings.

- Popping or creaking: sheet metal expanding or contracting from high static pressure or tight ducts.

- Buzzing, humming, clicking: failing contactor, relay, capacitor, or a hard-starting motor.

- Squealing or whining: worn blower bearings or a loose belt.

- Rattling or clanking: loose panels, screws, joints, or debris.

- Grinding or scraping: metal contact from failed bearings or blade rub. Power off.

- Hissing: air leaks at ducts or registers, or a refrigerant leak with weak cooling.

Vents nearest the blower transmit more sound, so noises there often begin at the air handler. Long straight metal runs, abrupt turns, compressed flex, thin or uninsulated ducts, and blocked returns can amplify rumble, popping, and whoosh, sometimes into a blower howl.

Rattling, clanking, or knocking: loose parts and debris (how to quiet them)

Power off at the breaker, then hunt for anything that can wiggle. Rattles commonly come from loose access panels, screws, or blower door latches. Tighten every accessible screw and snug the blower door until it seats firmly. Duct panels and straps that are loose or unsupported can vibrate with airflow, so add or tighten hangers to support any sagging runs. Twigs, leaves, or small objects can strike blower or outdoor fan blades and create clanks or bangs, clear the debris before restoring power. Noisy supply or return grilles often buzz like a loose picture frame, reseat them and add foam gaskets or butyl tape behind the frame to isolate vibration. In our experience at Budget Heating (BudgetHeating.com), the fix is simple physics, if metal can move, it can make noise, and mechanical fastening removes the play that causes it.

Hissing or whistling: airflow problems vs. refrigerant leaks (how to tell and what to do)

We hear both sounds in homes. A whistle usually means airflow is fighting a blockage, like a tea kettle. Start with basics: replace a dirty filter and make sure supply and return vents are open and unblocked. If ducts whistle, leaks or high air velocity may be the cause, sealing accessible joints and rebalancing dampers can quiet it.

A true hiss near the indoor coil or line set, paired with weak cooling, frost on the suction line, or oily residue, points to a refrigerant leak. Turn the system off immediately to prevent damage and contact a licensed technician.

Buzzing or humming: electrical and compressor issues (what to check and try)

In our experience at Budget Heating (BudgetHeating.com), a buzz that follows the power often points to electrical parts. Failing contactors or capacitors can buzz like a tired light. Compressors may hum from stress, loose mounts, or internal faults.

- Power off at the disconnect, clear debris, and confirm the outdoor condenser pad is level and stable.

- Tighten loose access panel screws.

- Inspect refrigerant lines. Replace deteriorated foam and keep clamps from transmitting vibration to the structure.

- Listen at the control panel. If the buzz persists or the compressor strains to start, stop and call a pro.

Persistent electrical buzzing or compressor noise usually requires a licensed technician with electrical and refrigerant tools.

Squealing or whining: belts and blower issues (safe fixes and next steps)

We always start by cutting power at the breaker. With a flashlight, inspect the blower. If your unit uses a belt and it is reachable without entering any control compartment, look for cracks, glazing, frays, or slack. Re-tension via the motor slide or replace with the identical size, only if you can safely access it with power off. Spin the blower and motor by hand. Roughness or wobble points to failing bearings. Some motors have service ports; apply only the manufacturer specified oil and only on serviceable models. If squealing returns or persists, expect professional bearing or motor replacement to avoid rapid failure.

- Basic tools: screwdriver or nut driver, small wrench, flashlight.

- Safety: avoid opening electrical control compartments. Do not over tighten belts, target about 1/2 inch deflection mid span.

Grinding or scraping: immediate shutdown and professional repair

Grinding or scraping is a red flag, shut the system down immediately. Do not run the unit. Metal-on-metal contact can quickly ruin a motor or compressor and create safety risks. In our field experience, this is not a DIY moment. A technician will check bearings, blower-wheel clearance, and shaft alignment, then replace failed parts as needed. Avoid improvised fixes to prevent catastrophic damage.

Simple DIY fixes, safety steps, maintenance & tradeoffs: what you can do, and when not to

Quieting and smoothing HVAC operation often comes down to airflow, vibration control, and routine care. Here is what typically works before calling in deeper service.

- Keep a small toolkit: flashlight, screwdriver set, adjustable wrench, vacuum with brush, butyl or foam gasket tape, mastic or UL-181 foil tape, work gloves.

- Replace or clean filters every 1 to 3 months to prevent high static pressure and whistling.

- Open all supply and return vents. Do not close registers to quiet one room, it makes other vents louder.

- Set the thermostat fan to AUTO and use dehumidify modes when sticky air is extending run time.

- Tighten grille and access panel screws with power off, and add foam gaskets to stop buzzing.

- Seal visible duct leaks with mastic or UL-181 foil tape, not cloth duct tape.

- Check condensate drains and traps for partial blockages, clear minor clogs to stop gurgling or chattering.

- Add rubber isolation pads under outdoor units and cushion line-set wall penetrations to cut vibration.

Safety matters: do not open electrical panels or touch capacitors or wiring, and do not attempt refrigerant diagnosis or charging. When issues involve refrigerant leaks, motor or compressor failures, electrical diagnostics, duct redesign or balancing, or measured static pressure testing, it is a professional scope. Small DIY fixes usually cost low double to low triple digits. Motors or compressors land mid three to four digits. Full replacement is typically higher four to five digits.

Plan an annual tune-up, ideally spring and fall. A technician should tighten fasteners, clean coils and blower wheels, test capacitors and contactors, measure static pressure, inspect and seal ducts, and verify refrigerant charge. In hot and humid climates systems run longer. Cold-climate heat pumps can thump during defrost and that can be normal. SEER2 reflects higher real-world static, so poor ducts raise noise and drop efficiency.

Honest tradeoffs: if ducts are undersized or restrictive, DIY will not solve it. Ask for Manual J, S, and D with static tests. If equipment is aging and inherently loud, consider variable-speed blowers, inverter compressors, a compressor-rated sound blanket, or a new quiet high SEER2 unit. If a compressor or bearings are failing, replacement may be wiser than repair.

Next steps: Quiet your HVAC, protect your system and when to get help

Noisy HVAC is rarely normal. It often points to a dirty filter, airflow restriction, loose parts, or a failing component. Fixing it early improves comfort, evens airflow, saves energy, extends equipment life, and helps indoor air quality.

If the sound persists or hits a red flag, you are right to act. Document it, do only safe checks, then shut the system off and contact a licensed HVAC technician.

- Get a Custom Quote: right size, parts or replacements, wholesale pricing.

- Talk to Our Team: U.S.-based phone support by real HVAC techs.

- Shop Filters & IAQ: restore airflow and reduce noise.

- Shop Heat Pumps, AC and Air Handlers: most systems ship free, Affirm available.