Package Unit vs Split System: Which Is Right for You?

Choosing between a packaged HVAC unit and a split system is a high impact decision that shapes comfort, energy bills, indoor air quality, and equipment lifespan. A packaged unit places all major components in one weatherproof outdoor cabinet. A split system separates the outdoor condenser and compressor from an indoor air handler or furnace. Think of it like picking an all in one appliance versus a component setup. From years of field installs and replacements, the best choice usually tracks with your building layout and what is already in place.

- Layout and space: Tight attics, closets, or crawlspaces often favor packaged. Ample indoor space suits split systems.

- Ducts: Existing duct condition and routing can steer the choice. Packaged units tie into roof or slab ducts, splits tie into indoor supply and return.

- Efficiency: Split systems usually offer broader efficiency options and quieter indoor operation. Packaged models prioritize simplicity.

- Maintenance: Packaged units centralize service outdoors but face weather. Splits spread components, with key parts protected indoors.

- Climate: Hot, mild regions often suit packaged simplicity. Colder climates may benefit from split systems with tailored heat options.

What Is a Packaged Unit? Definition, Components, and When It Fits

A packaged unit is a self-contained HVAC system that consolidates the evaporator, condenser, compressor, and often electric heat or a gas furnace into a single outdoor cabinet. It sits on a rooftop curb or ground pad, with supply and return ducts connecting to the building.

Because all components are outdoors, packaged units minimize the indoor mechanical footprint, keep equipment out of living areas, and can simplify replacement in homes without basements, crawlspaces, or utility closets. In our field work, we most often see them serve smaller homes, slab-on-grade construction, manufactured homes, and low-rise buildings where space for an indoor air handler is limited.

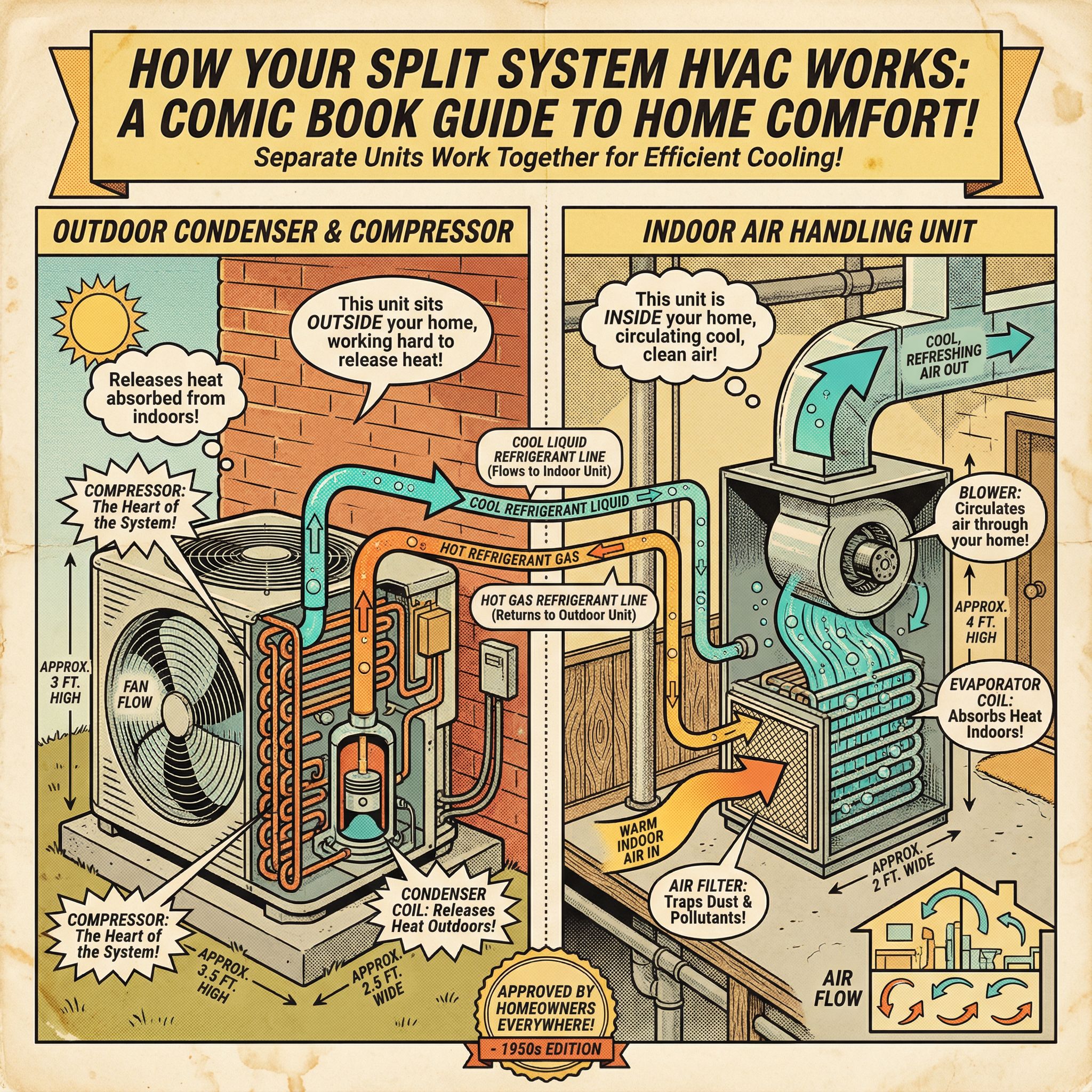

What Is a Split System? Components, How It's Laid Out, and Ideal Homes

A split system separates the outdoor condenser and compressor from an indoor unit that contains the evaporator coil and blower. In gas heat homes, the indoor piece may be a furnace with a coil. The halves connect by refrigerant lines, a condensate drain, and low-voltage wiring, and the indoor blower moves air through ductwork.

This separation matters for layout. You need indoor mechanical space, typically an attic, basement, crawlspace, closet, or garage. The payoff is flexibility, since ducts can branch efficiently to distant rooms, which suits larger footprints and multi-story homes. We often see housing in many Southeast metro areas designed for indoor air handlers, so those homes naturally default to split systems because the housing stock already accommodates the equipment.

Energy Efficiency & Performance: SEER, SEER2, EER and Real-World Savings

SEER and SEER2 rate seasonal cooling efficiency, similar to miles per gallon for air conditioning. SEER2 uses updated test procedures and usually posts slightly lower numbers than legacy SEER for the same unit, so compare like to like. Higher SEER or SEER2 means fewer kilowatt-hours across a season, which shows up as lower utility bills. Since 2023, DOE regional minimums for SEER2, HSPF2, and EER2 apply. Central split heat pumps carry higher nationwide minimums, while single-packaged systems follow different baselines.

EER and EER2 focus on steady-state efficiency at a set condition. Testing and labels already account for small baseline EER differences between system types, and older baselines often required slightly higher EER for splits than packaged. Split systems and mini-splits typically offer the highest SEER2 and more variable-speed options, so in long cooling seasons they can deliver better real-world efficiency than packaged units. In our experience at Budget Heating (BudgetHeating.com), homeowners in hot climates see the biggest bill impact from stepping up to a higher SEER2 or a variable-speed split, while packaged units remain a practical, code-compliant choice where space or rooftop constraints drive the design.

Installation & Space Considerations: Roofs, Pads, Ducts and Permits

Site conditions often decide what will fit, run quietly, and pass inspection. We start with a structured checklist to avoid surprises.

- Identify the existing system and duct layout, then note clearances and utilities.

- Evaluate duct condition and static pressure. Ducts are the air highway, bottlenecks raise pressure and cut airflow.

- Confirm indoor air-handler space if applicable: attic, basement, or closet access, service clearances, and condensate routing.

- Favor like-for-like replacements when the shell and ducts are sound to minimize retrofit work.

Insist on proper sizing and design: a Manual J load calculation and Manual S equipment selection. Request Manual D duct design or, at minimum, static-pressure and airflow verification before equipment is finalized.

Rooftop installations require extra planning: verify structural capacity, curb and rail details, weather flashing, drainage paths, and crane access. Expect permit complexity for roof penetrations, anchorage, and load documentation, and lock in crane dates early. For ground installs, provide a level concrete pad, maintain manufacturer clearances, and slope grading so water drains away from the unit.

Key Differences at a Glance: Packaged Unit vs Split System

In our experience at Budget Heating (BudgetHeating.com), most homeowners compare four essentials.

- Footprint: Packaged centralizes all equipment outdoors, freeing indoor space. Split separates components, needs an indoor air handler, and offers placement flexibility.

- Customization: Splits support zoning, advanced filtration, humidity control, and variable speed compressors. Packaged units have fewer ultra high efficiency or variable speed options.

- Noise: Packaged keeps nearly all mechanical noise outside. Splits have indoor blowers and outdoor condensers, and careful placement can reduce perceived noise.

- Regional norms: Packaged is common in Sunbelt and flat roof markets. Splits dominate many regions, for example much of the Southeast, with homes built for indoor air handlers.

Limitations and Tradeoffs: When Neither System Is Perfect

We see two myths trip people up. First, that packaged units are always more efficient. In practice, split systems usually achieve higher SEER or SEER2 and offer more advanced compressor and control options. Second, that there is one best choice. The right fit depends on layout, available ductwork, efficiency targets, climate, and budget.

- Chasing the lowest long-term energy use: Packaged units often top out at lower efficiency tiers. A high-efficiency split system or a ductless mini-split typically delivers better seasonal savings and finer control.

- Harsh coastal or exposed sites: Because packaged units live entirely outdoors, salt and wind can accelerate corrosion and service needs. A split system, with its air handler indoors, usually holds up better. Ductless mini-splits also keep critical components inside and can reduce outdoor wear.

- Very cold climates or frequent cold snaps: Heat pumps alone may struggle to meet comfort expectations at the lowest temperatures. A gas furnace, either as primary heat or as a backup, is often the more practical solution.

- Tight indoor mechanical space: Traditional split systems may be hard to fit when closets or basements are scarce. In those cases, a packaged unit solves the footprint issue. Where zoning is a priority, ductless mini-splits can serve well with minimal indoor space.

No single configuration wins every scenario. Matching equipment to the home and climate is what delivers reliable comfort and value over time.

Maintenance, Repairs, and Lifespan: What to Expect Year to Year

Because all components sit outdoors, packaged units see weather, debris, pests, and coastal salt air. That exposure increases cleaning needs and can shorten lifespan compared with split systems that keep air handlers inside. Think of it like keeping a bicycle on the porch versus in the garage.

Homeowner-safe routine:

- Check or replace filters every 1 to 3 months.

- Keep supply and return grilles clear.

- Maintain 2 to 3 feet of clearance around the cabinet.

- Shut off power, then gently rinse coils.

- Check thermostat batteries.

Leave to licensed technicians:

- Refrigerant diagnostics and charging.

- Electrical repairs and controls.

- Combustion or heater service.

- Rooftop unit access and servicing.

- Deep coil and blower cleaning.

- Duct modifications or sealing.

Cadence: homeowners do monthly visual checks and filter care. Schedule professional maintenance twice yearly, before cooling and before heating seasons.

Cost Comparison: Equipment Price, Installation, and Lifetime Ownership

Total cost of ownership equals equipment price plus installation plus energy over 10 to 15 years. Start with the quote: the unit itself, then labor and any site work. Installation swings are common, and we see them driven by:

- Crane fees for rooftop packaged units

- Refrigerant line-sets and wall penetrations for splits

- Electrical upgrades

- Duct repairs

- Permits

- Disposal of old equipment

Energy is the long tail. At $0.14/kWh, illustrative annual cooling costs show the trend: 13 SEER about $620, 14 SEER about $576, 16 SEER about $504, 18 SEER about $448. That stepdown is what can repay a higher upfront price, especially in hot climates with long cooling seasons. Compare itemized quotes side by side and add projected energy use over 10 to 15 years to see which option truly costs less.

Conclusion: How to Choose, A Practical Recommendation

If indoor mechanical space is limited or a roof or pad install is simple, a packaged unit is the clean, all-in-one swap that keeps equipment out of living areas. If you have indoor space and prioritize higher efficiency, zoning, quieter comfort, and long term operating cost savings, a split system is usually the better fit.

Now weigh site constraints, existing ductwork, local efficiency and refrigerant rules, climate, noise goals, and total cost of ownership. Then ask a qualified contractor for a Manual J and side-by-side, code compliant proposals. Our team can help you compare, drawing on 30+ years of hands-on HVAC experience.

- Get a Custom Quote for your home, including wholesale pricing, many items ship free, financing with Affirm.

- Talk to Our Team for U.S.-based phone support and practical system sizing help.

- Shop Packaged Units built for simple, all-in-one installs.

- Shop Split Systems for higher efficiency and quieter indoor comfort.