Introduction: Why HVAC Differences Matter in Mobile (Manufactured) vs Site-Built Homes

Heating and cooling are essential in both home types, but construction choices change what works best. Manufactured and mobile homes often use underfloor belly ducts and a single central return. Site-built homes typically run ducts in attics or basements with multiple returns. Many manufactured-home systems are factory listed and shipped as matched packages, while site-built equipment is usually field selected and installed.

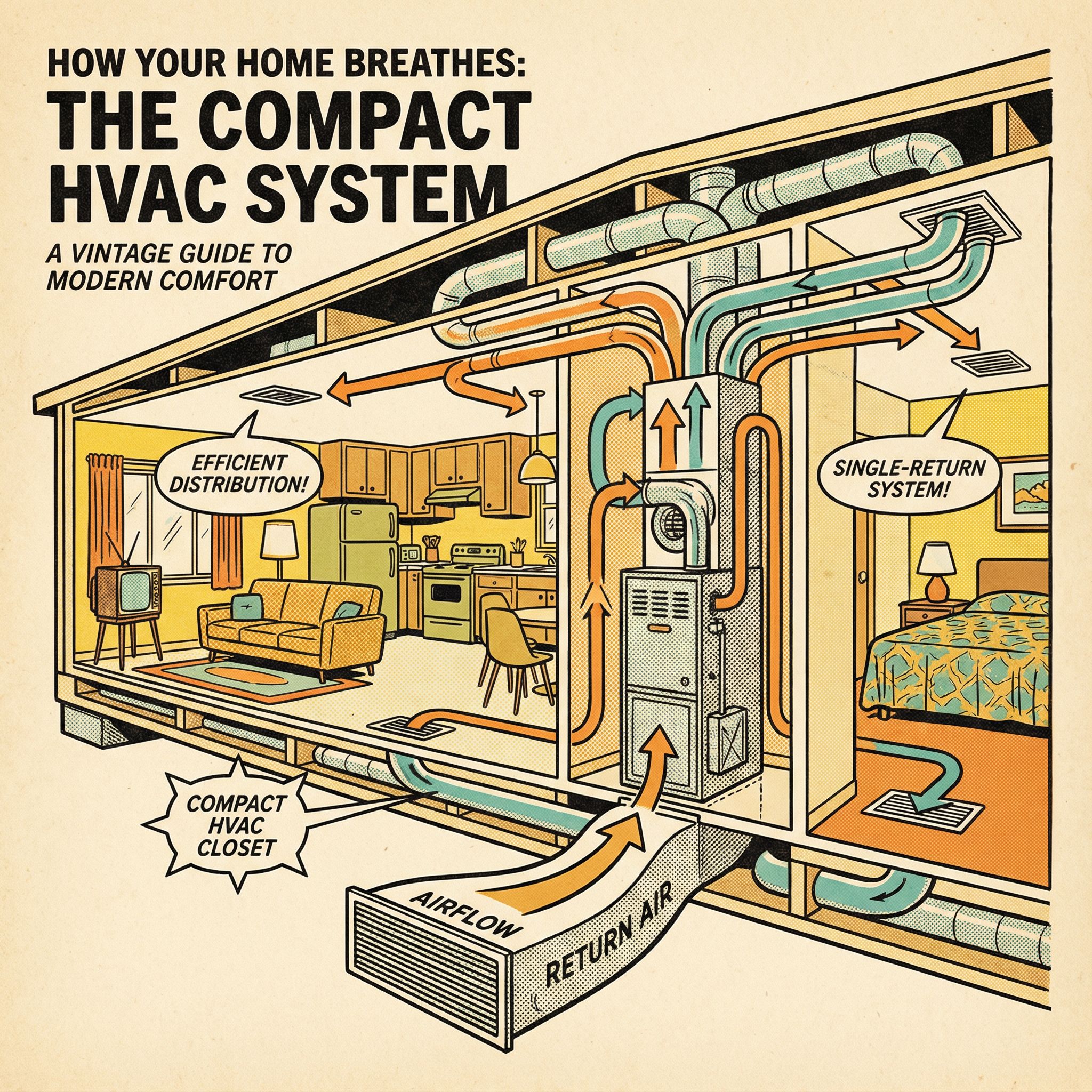

Those differences affect airflow, static pressure, and heat loss paths, which shape comfort room to room, energy bills, indoor air quality, and equipment life. A single return needs door undercuts or transfer grilles to keep air moving. Underfloor ducts need tight sealing and insulation to prevent condensation and leakage. Factory-listed packages should not be mixed with non-listed parts, and field-built systems depend on correct sizing and commissioning. Think of the house as lungs: where the ducts live and how air returns determines how well it breathes.

Permits, Codes and Regulations: HUD vs Local Building Codes and the SEER2 Transition

Manufactured or mobile homes are governed by the federal HUD Code (24 CFR Part 3280), which preempts local building codes for the factory-built unit. HVAC appliances must be specifically listed for manufactured housing. Site-built homes follow local adoptions of the IRC, IMC and IECC, with system sizing and design based on ACCA design manuals. Think of HUD like a federal passport that sets the rules wherever the home goes.

In 2023, DOE shifted to SEER2, EER2 and HSPF2 test procedures. Ratings changed and no longer match legacy SEER or HSPF values. Regional minimums differ between the North and the Southeast or Southwest, and EER2 rules apply in the Southwest. These updates affect compliance and equipment selection for both home types.

Common HVAC Systems in Manufactured/Mobile Homes: What You'll Usually Find

Manufactured homes typically use HVAC equipment that is specifically listed for manufactured housing, often labeled HUD or mobile-home approved. Indoors, the air handler or furnace is usually compact, downflow, and matched to smaller duct systems with modest static pressure. Factory setups commonly leave a utility closet and short trunk lines sized for these units.

Many homes use packaged units outside to save indoor space and simplify connections. Split systems, including heat pumps, are also common when they are properly sized and installed for the home's ductwork and airflow limits.

- Myth: Site-built equipment is fine in a mobile home. Reality: Use equipment rated for manufactured housing to meet airflow, clearance, and safety requirements.

- Myth: Bigger is better. Reality: Oversizing can create uneven temperatures and premature wear. Correct sizing protects comfort and components.

- Myth: Higher MERV always helps. Reality: Small ducts struggle with added resistance. Think of breathing through a thin straw. Use low-resistance filters approved for the unit.

Tradeoffs to consider: if you want larger return and filter areas, a split system can be a better fit than a packaged unit. If the home's ducts cannot handle added pressure, high-MERV filters are not ideal, stick with low-resistance options. If equipment is not HUD approved, it is not the right choice for a manufactured home, select listed models only.

Typical HVAC Systems in Site-Built Homes: More Space, More Options

Site-built homes typically use conventional split systems, an indoor air handler or furnace paired with an outdoor condenser or heat pump. With attics, basements, or closet mechanical rooms, installers can fit larger supply plenums and run separate return ducts to key rooms. Think of it like adding extra lanes to a highway, airflow is smoother and equipment choices widen. That space lets us specify higher-capacity air handlers, bigger coils, and variable-speed blowers that can actually achieve their rated performance.

Ducts are often routed in conditioned or semi-conditioned areas, which lowers leakage and heat gain. The result is a better chance of hitting nameplate SEER2 or HSPF2, quieter operation, and improved filtration thanks to dedicated returns. In our experience at Budget Heating (BudgetHeating.com), this layout supports high-efficiency heat pumps, two-stage or modulating furnaces, and advanced controls without the compromises that come with tighter, under-floor duct setups.

Installation Challenges, Access & Maintenance: What Installers and Homeowners Must Watch

Manufactured homes often arrive with HVAC in compact closets, downflow only, sealed combustion, and strict clearance and venting rules. Never store items in the furnace closet. Access is tight, routing refrigerant and drain lines and placing the outdoor unit near skirting require care, and some components may sit under the home. Site-built homes usually allow flexible locations and service clearances. We design straight service paths and code-compliant airflow around equipment.

- Homeowner tasks: replace filters, rinse outdoor coils, keep the pad level, clear debris.

- Professional only: refrigerant, electrical, combustion. Schedule annual or biannual tune-ups. If a CO alarm sounds or you smell gas, leave and call the utility or 911.

Ductwork & Distribution: Single-Return Closet Systems vs Multi-Return Duct Networks

In many manufactured homes, the furnace or air handler breathes through a single return path, often a louvered closet door. Returns are the system's inhale: if that path is noisy, undersized, or blocked, rooms lose airflow. Site-built homes usually have trunk-and-branch supply with multiple return grilles that balance pressure.

Manufactured ducts are smaller and run in the belly under the floor, so access is limited. Seal seams and boots, insulate the belly, and straighten kinks to cut energy loss and condensation. Multi-section homes rely on a crossover duct, often the leakiest point. In our experience at Budget Heating (BudgetHeating.com), tight connections, mastic not tape, and insulated crossovers deliver big comfort gains.

Sizing & Load Calculations: Why Mobile Homes Need Different Approaches

Manufactured-home ducts have lower available static pressure and smaller trunks, so airflow tolerances are tight. Blowers and filters must be matched, and high-MERV filters or blocked returns can quickly choke airflow.

Right-sizing is critical. Rule-of-thumb tonnage often overshoots, leading to short cycling and uneven rooms. Prove the selection in the field by measuring total external static pressure and delivered CFM, then compare results to the equipment fan tables.

- Use MH-aware Manual J or ENERGY STAR manufactured-home sizing, and verify proposed tonnage against floor area, insulation, and layout.

- Confirm filter size and type keep pressure drop acceptable at design airflow, and that return air is adequate.

Energy Efficiency & SEER2: What the Numbers Mean and Cost Impacts for Mobile vs Site-Built Homes

Think of SEER like miles per gallon for cooling. The DOE shifted to SEER2, EER2, and HSPF2 in 2023, using tougher test conditions, so SEER2 ratings read lower for the same hardware. Typical ranges: older systems SEER 8-10. Today's baseline is mid-teens SEER2, about 14-16. Premium variable-speed units reach 18-25+. As a rule of thumb, upgrading from SEER 10 to SEER 13 cuts cooling energy about 23 percent, and SEER 10 to SEER 16 about 38 percent.

Manufactured homes usually have 60-70 percent higher energy cost per square foot than site-built homes, so moving to mid-teens SEER2 can deliver big dollar reductions even if the percentage varies. In our experience at Budget Heating (BudgetHeating.com), site-built homes tend to realize lab-rated savings more predictably, while manufactured homes benefit greatly but are more sensitive to duct leakage and envelope gaps. Seal ducts and tighten the envelope to capture the full 23 to 38 percent instead of leaving savings on the table, especially in manufactured homes where the baseline energy intensity is higher.

Checklist: Steps to Replace or Upgrade HVAC in a Mobile Home

Use this homeowner checklist to keep your manufactured home HVAC project clean and code friendly. In our experience at Budget Heating (BudgetHeating.com), these steps prevent surprises and ensure comfort.

- Identify your home type and current equipment location.

- Request Manual J or MH-aware sizing, never guesswork.

- Confirm return-air design and that louvers or grilles are unobstructed.

- Measure total external static pressure and inspect all ducts, including crossover.

- Choose a system compatible with the closet, ducts, and proper HUD mobile-home listing.

- Plan access, clearances, and venting per the install manual.

- Compare efficiency ratings, SEER2, HSPF2, and AFUE.

- Check filtration and IAQ options, such as media filters or UV.

- Site the outdoor unit on a level pad with required side and top clearances.

- Get an itemized scope, permits, and warranty terms in writing.

- Require post-install verification: static pressure, CFM per ton, temperature split, condensate routing and trap checks.

Conclusion: Choosing the Right HVAC Path for Your Home Type and Budget

Manufactured homes need compact listed downflow units and underfloor ducts that are sensitive to static pressure and leakage, while site-built homes suit flexible split systems with separate returns and better protected ductwork. Right-sizing, code-compliant installation, and regular maintenance matter in both.

Whether you own, manage, or install, you want upgrades that fit the home and the budget without sacrificing airflow.

Our team helps select listed equipment for manufactured homes, verify return paths, seal and insulate ducts, and pair higher SEER2 or variable-speed heat pumps with duct and envelope work for dependable savings.

- Get a Custom Quote

- Talk to Our Team by phone for fast support

- Shop Mobile Home HVAC, Split Systems, and Heat Pumps