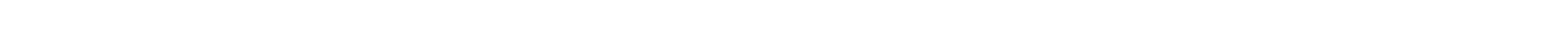

Is Your 12-Year-Old AC a 2026 Disaster Waiting to Happen? (Quick Answer)

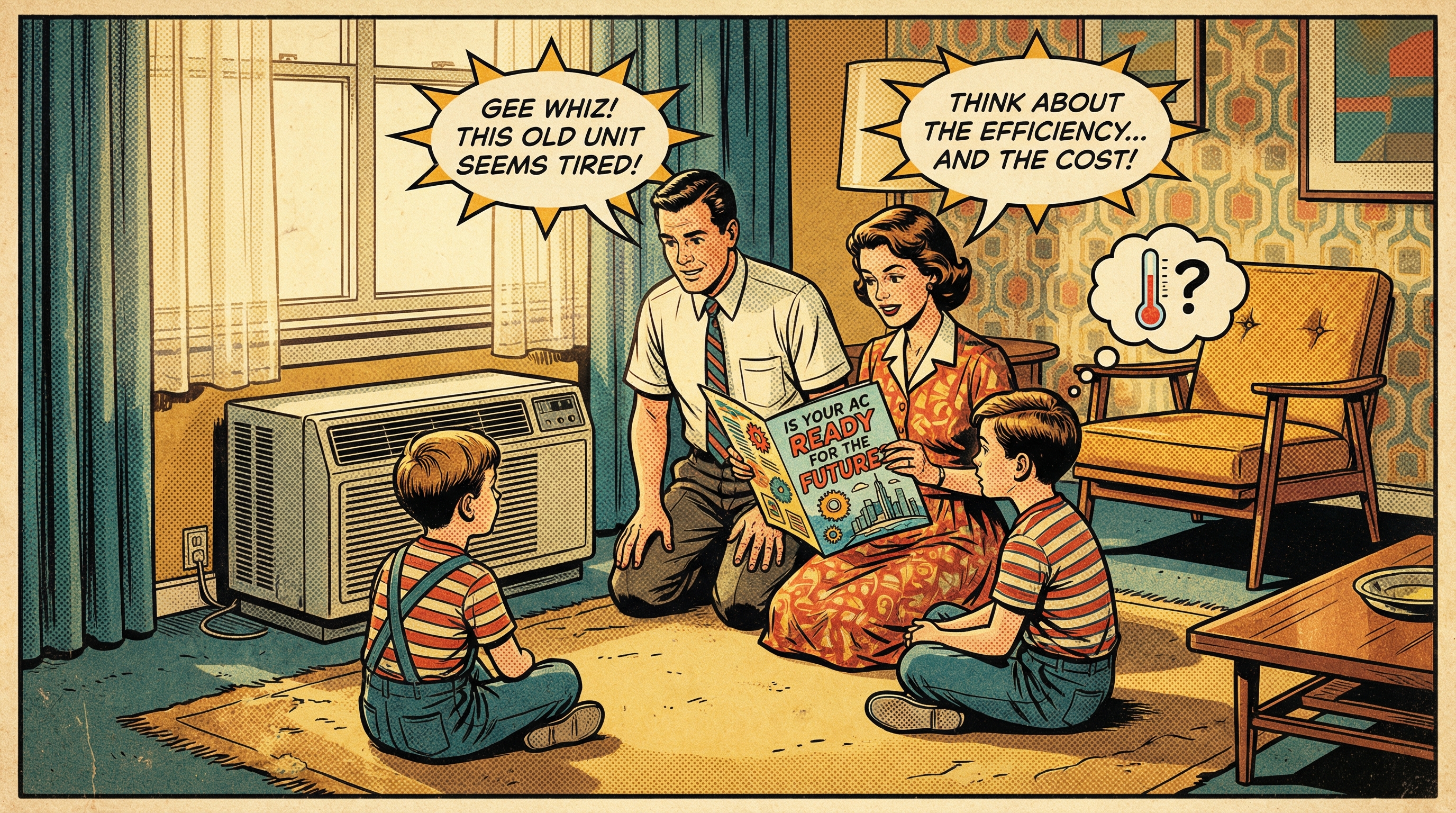

If your central AC is around 12 years old, you are at a pivotal point. The industry median life lands around 12 to 15 years, and by year 10 many systems are only delivering about 80 to 85 percent of their original efficiency. That means comfort slips, run times stretch, and bills creep up even when nothing is technically broken.

From decades in the field, this is also when nuisance issues start to stack up. Think of it like a car that used to get 30 mpg but now gets 24 to 25. It still drives, but every mile costs more and the chance of a roadside stop rises.

With 2026 approaching, the smart move is to shift from reactive fixes to proactive planning. Identify whether you will nurse the system through one or two more seasons or map a replacement timeline. Getting ahead of the curve reduces stress and helps you make measured choices instead of rushed ones when heat waves hit.

Why Age 12 Matters: Lifespan, Wear Patterns and Regional Risk Factors

Year 12 is a tipping point for many residential AC systems because it sits in the middle to near end of the typical 12 to 15 year lifespan. By this stage, the equipment may still cool, but the years of cycling begin to show up as higher stress, longer run times, and rising utility use. Think of it like tires after thousands of miles, they still roll, but grip and efficiency are not what they were.

The core parts have accumulated thousands of starts and thermal cycles. Compressors, fan motors, capacitors, and coils are nearing the end of their design life, which raises the chance of failure. Electrical components weaken with heat, bearings and windings see fatigue, and coil surfaces lose performance as microfouling builds. This gradual degradation does not always announce itself with a breakdown, it often hides in the form of extra minutes per cycle and poorer humidity control.

Local climate speeds this curve. Harsh regions shorten useful life and magnify both failure risk and the cost of inefficiency:

- Hot or long cooling seasons, more hours and cycles per year.

- Humid areas, added latent load and moisture stress on parts.

- Coastal environments, salt exposure and corrosion on coils and metals.

- Dusty or desert locations, clogged coils and fans that drive longer runtimes.

Regulatory & Market Changes to Watch in 2026: SEER2, Refrigerants, and Parts Availability

SEER2 replaced SEER starting in 2023. It uses tougher test conditions, including higher external static pressure, so the same piece of equipment will often show a lower SEER2 number than its old SEER rating. Think of it as using a new yardstick to measure the same system. At the same time, the DOE sets regional minimums, and new baseline central systems are effectively pushed into the mid teens on SEER2, with exact minimums varying by region.

The U.S. is phasing down high GWP refrigerants like R 410A and legacy R 22 in favor of low GWP A2L options such as R 32 and R 454B. New installs will broadly shift to these A2L blends around 2026 to 2026. Existing R 410A and R 22 systems can keep running, but expect rising costs for recharges and service as supplies tighten, and R 22 is already costly. In our experience at Budget Heating (BudgetHeating.com), the surprise for many homeowners is how quickly those refrigerant costs change the math on repairing an older unit.

Before 2026, confirm your contractor is trained and certified for A2L refrigerants, including code, ventilation, and leak detection requirements. Also expect longer lead times and higher prices tied to refrigerant service on legacy equipment.

Top 8 Signs Your AC Could Fail This Summer (What to Watch For)

Use this quick risk checklist to decide when to schedule a pre season check or start replacement planning. In our experience at Budget Heating (BudgetHeating.com), these symptoms tend to snowball if ignored.

- Short cycling: rapid starts and stops that point to control issues, low charge, or an oversized system.

- Much longer run times: needs far more time to hit setpoint, a sign of lost capacity or efficiency.

- Inconsistent temperatures: hot and cold spots or failure to keep up on very warm days.

- Reduced airflow: weak vents from clogged filters, dirty coils, or a fatigued blower.

- Poor humidity control: rooms feel clammy or stale even when the thermostat shows cold.

- Noisy or unusual sounds: new banging, rattling, or loud hums that suggest motor or compressor wear.

- Ice or refrigerant clues: frost on the evaporator or suction line, oily residue at joints.

- Frequent or major repairs: repeated service calls or recent big fixes signal more failures ahead.

If you check two or more boxes, you are on borrowed time, like a car that hesitates at every light.

Repair vs Replace: A Practical Calculator for 12 Year Old Units (Honest Tradeoffs)

At about 12 years, judge the unit by a checklist: refrigerant, size and frequency of repairs, utility bills, comfort issues, remaining warranty, and local climate. If a single repair quote is roughly 25 to 50 percent of a new, properly sized system, evaluate replacement. R 22 units, and some R 410A as supply tightens, often flip the math because leak repairs and recharges get expensive. If replacing, require a Manual J load calculation with Manual S and D so equipment and ducts actually match.

- "If it still cools, it is fine": efficiency and reliability may be slipping.

- "Wait until it dies": breakdowns and peak season premiums hurt.

- "2026 will make my unit illegal": existing systems can still be serviced.

- "Cranking the thermostat": it will not cool faster.

- "Higher SEER alone": comfort needs duct and airflow fixes.

- "Oversizing is better": causes short cycling and humidity.

- "Skip maintenance": a $150 tune up can prevent a $2,000 failure.

Repair is reasonable with low run hours, a single minor failure, or when selling soon. Replacement is not ideal before a remodel, with hard duct constraints, or in very mild climates. Interim options include targeted repairs or portable dehumidification.

How Much Will Replacement Cost in 2026? Typical Ranges and What Drives Price

In our experience, 2026 replacement pricing spans a broad range, driven less by a single sticker price and more by a stack of line items that add up.

- Equipment tier: Higher SEER2 units cost more up front.

- Sizing and design: Proper Manual J/S sizing prevents overspend and future inefficiency.

- Ductwork: Repairs, sealing, or retrofits add material and labor.

- Electrical and permits: Panel or circuit upgrades plus local permits impact totals.

- Installation quality: Commissioning steps, including evacuation to 500 microns and verified charge, take time and skill and are worth budgeting for.

- Purchase channel: Buying through wholesale or reputable online sources can reduce equipment cost about 20 to 40 percent, with lower shipping on larger bundles.

- Incentives: Federal, state, and utility rebates can shift net cost significantly. Confirm eligibility in advance and keep model, serial, and AHRI match certificates.

- Repair vs replace: For systems over 10 years, budget for refrigerant or major component repairs, then weigh those costs against replacement.

Energy Savings & Payback: How a New High SEER Unit Lowers Your Bills

From years of field checks, we see efficiency slide as equipment ages. A 13 SEER unit can effectively run like 9 to 10 SEER after about 12 years due to coil fouling, charge drift, wear, and motor losses. The result is 25 to 35 percent more electricity for the same cooling, often $300 to $600 extra per year in warmer climates. Many legacy units now operate well below current SEER2 baselines, which creates a real energy savings opportunity.

Upgrading a tired 10 to 13 SEER system to a modern 15 to 20+ SEER2 unit can cut cooling energy use about 30 to 50 percent. Example for a 3 ton system in a warm climate: roughly $750 per year down to about $490 at 15 SEER or about $435 at 20 SEER. Payback is straightforward: divide your net upgrade cost by annual savings. With $260 to $315 saved per year in this scenario, each $1,000 invested returns in about 3.2 to 3.8 years.

Maintenance You Can Do Now to Buy Time (Checklists, Intervals, and Safety)

- Filters: We recommend a monthly check, then replace or wash every 1 to 3 months, depending on filter type and dust. Keep return and supply grilles unobstructed.

- Thermostat: Verify mode and schedule. Replace batteries annually or at low alerts.

- Condensate: Turn power off at the breaker. Where accessible, flush the trap or drain line with a small vinegar rinse, then confirm the float switch or other drain safety devices are in place.

- Outdoor unit: Maintain 2 to 3 feet of clearance. Gently rinse coils with a garden hose from inside to out. Do not use a pressure washer.

- Limits and warnings: Do not open refrigeration sections, add refrigerant, use stop leak, or work on high voltage. If you notice new noises, rapid short cycling, or visible ice, call a pro.

How to Prioritize Repairs and Emergency Steps If You Can’t Replace Right Away

We triage repairs in this order: safety, system protection, comfort. Follow this checklist when you must keep an older system running:

- Combustion: Furnaces or rooftop units with burner, heat exchanger, or gas valve issues require qualified combustion techs. CO risk is real.

- Electrical red flags: Burning smells, frequent breaker trips, failed capacitors, motors that will not start, or control faults. Cut power at breaker and disconnect, never attempt high voltage work, use licensed service.

- Refrigerant: Ice on the evaporator or suction line, oily residue, or weak cooling. Only EPA Section 608 certified technicians should handle it.

- Protect the system on a budget: Verify correct breaker and disconnect size, seal obvious duct leaks, restore severely reduced airflow, avoid pressure washers on coils. Preseason, have pros check compressor health, contactors and capacitors, refrigerant charge, duct leakage and airflow, and condensate safety devices.

Next Steps: What to Do This Week if Your AC Is ~12 Years Old

Here is a focused plan to protect comfort and budget.

- This week: confirm unit age and refrigerant, replace filters, clear the outdoor coil area, and book a pre-season inspection to document condition and likely remaining life.

- Next 30 days: get a Manual J load calculation, gather 2 to 3 quotes, check rebates and utility incentives, and pick an install window before peak heat.

- Next 3 to 12 months: if you keep it, schedule maintenance (coil cleaning, charge and electrical checks), set a repair reserve, and stage a 2026-ready replacement plan.

Key insight: move from reactive to proactive, document, quantify, plan, and pre-book installation resources. A 12-year-old AC is higher risk, so replace on your schedule, not during a heat wave. We know this is a big call, and our team has 30+ years of HVAC experience to guide you.

- Get a Custom Quote

- Talk to Our Team by phone for U.S.-based support

- Shop Central AC and Heat Pump Systems

- Ask about free shipping zones and Affirm financing