Why HVAC Robotics and Automation Matter Today: Efficiency, Reliability and Savings

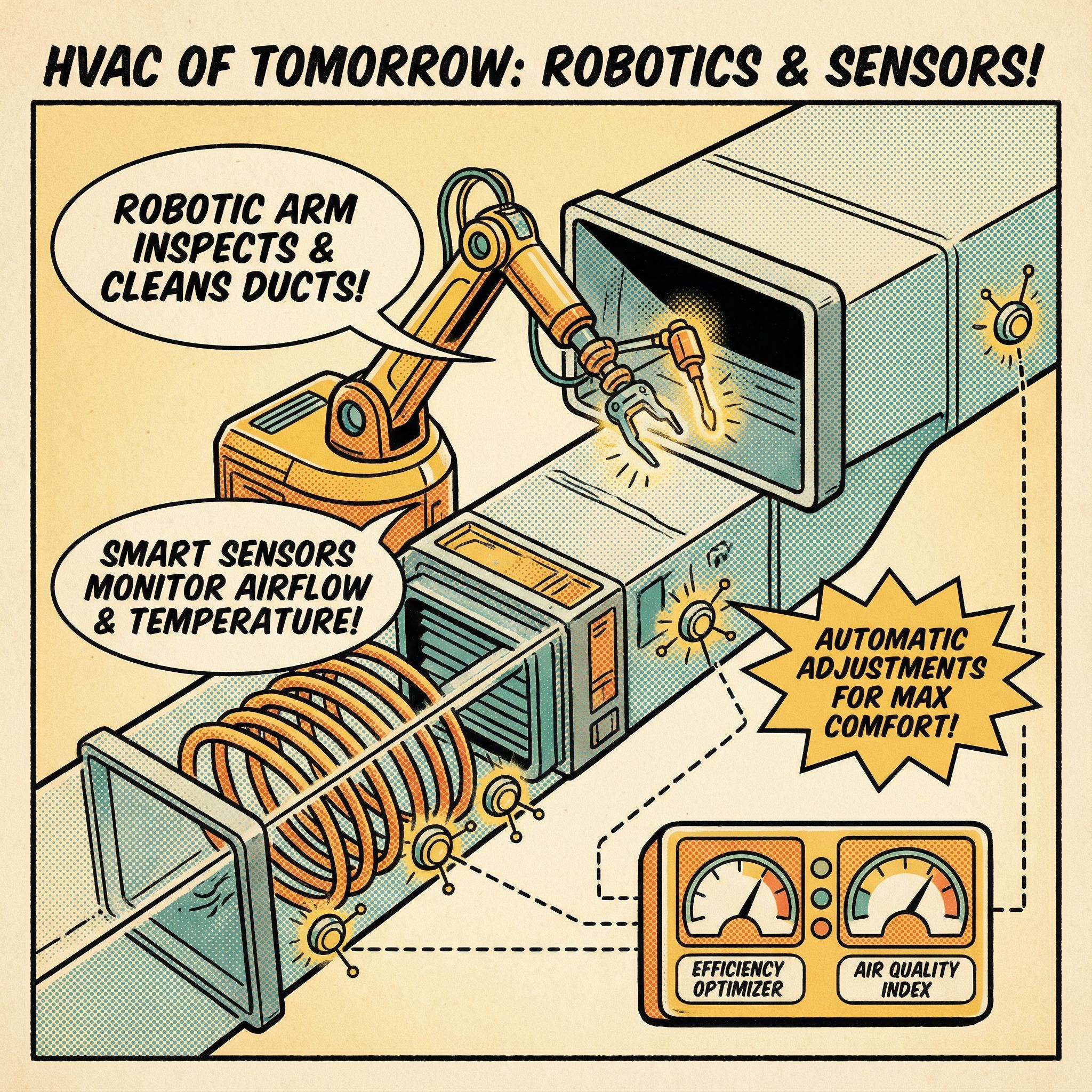

Heating and cooling dominate operating costs and define day-to-day comfort. Robotics and automation bring a steady hand to both: continuous monitoring, AI-driven controls and autonomous inspection keep equipment efficient, indoor air cleaner and life-cycle costs in check.

Automation, at its core, links smart sensors to a control brain that adjusts operation in real time. Temperatures, humidity, pressures and indoor air quality are read constantly, then setpoints, fan speeds and valves are tuned to match the load, like cruise control holding speed on a hill. Software corrects small drifts before they become big swings and coordinates zones to reduce hot and cold spots. When CO2 or particulates climb, ventilation and filtration can ramp up only as needed, protecting comfort without wasting energy.

Maintenance shifts from reactive to proactive. If coil temperatures trend out of range or vibration rises, alerts prompt simple fixes before failures develop. Autonomous inspection, from rooftop visual checks to camera crawlers in ductwork, verifies conditions and documents asset health between service visits. The result is steadier comfort, fewer surprises and equipment that operates closer to its design sweet spot for more of its life.

What HVAC Robotics and Automation Actually Are: Definitions and Core Components

HVAC robotics and automation is the coordinated use of robots, smart sensing, analytics, and controls to inspect, clean, and actively manage comfort and air quality. In homes and facilities, the pieces work together like a nervous system: sensors gather data, a control brain evaluates it, actuators and robots carry out precise adjustments or maintenance, and managers view results remotely. In practice, we connect these elements through a building management system or a smart hub to keep equipment responsive and predictable.

- Robotics: duct and coil crawlers for inspection, onboard cameras, and cleaning tools.

- Smart sensors: temperature, humidity, pressure, airflow, VOCs, and particulates.

- AI controls: learning algorithms that tune setpoints, staging, and fan speeds.

- BMS integration: centralized schedules, trend logs, alarms, and interoperability.

- Remote monitoring: secure dashboards, alerts, and historical reports.

- Field devices: actuators, dampers, valves, and VFDs that execute commands.

Core Technologies: Robotics, IoT, AI, Sensors and BMS Integration

Robotics handle the dirty work, inspecting coils, belts and duct interiors with cameras and brushes, while IoT sensors stream temperature, humidity, vibration and power data. AI ties it together, tuning setpoints, staging and airflow in real time, then hands commands to the BMS so changes roll out across one site or an entire portfolio. In our experience at Budget Heating (BudgetHeating.com), this mix reliably reduces waste and steadies comfort.

Continuous optimization is like cruise control that learns your route. The system studies weather, occupancy and equipment response, then modulates setpoints minute by minute. Buildings typically see about 15 to 20 percent energy improvement and notable maintenance savings. Predictive maintenance reads the same data to spot early warning signs, from rising coil delta T to bearing vibration drift, and schedules a quick fix before a failure. That means a $150 cleaning instead of a $2,000 compressor, fewer surprises, and longer equipment life.

SEER, SEER2 and Efficiency Ratings: Why Ratings Matter for Automation Decisions

Think of SEER like miles per gallon for cooling over an entire season. SEER2 is the newer, stricter test that better reflects real duct pressures and field conditions. In 2023, federal minimums shifted to SEER2, EER2 and HSPF2, so compare systems using those labels. Modern central systems typically span SEER 14 to 20+, and in our field work the higher the rating, the more a good control strategy matters to deliver the promised savings.

Automation ties the rating to reality. Smart thermostats, variable-speed blowers, staged or inverter compressors and sensors coordinate cycle length, airflow and setpoints so the unit operates in its most efficient band. Continuous optimization helps narrow the gap between lab ratings and lived results. When selecting, prioritize the SEER2 number, your climate, duct quality and the controls that will manage airflow and capacity from day one.

Practical Implementation Checklist for Homeowners and Facility Managers

Treat upgrades like a repeatable project: set targets, measure, then control. We follow this sequence:

- Define goals: comfort, humidity, noise, IAQ, electrification, resilience.

- Baseline: note utility use, room hot or cold spots, existing controls, filter sizes, and duct condition.

- System assessment: verify equipment type and age, nameplate capacity, static pressure, duct leakage, and ventilation paths.

- Select the automation brain: choose a controller or smart thermostat that matches stages or inverter logic, supports heat pump with auxiliary heat, dehumidification, zoning, outdoor sensors, data logging, open protocols when needed, and simple scheduling.

- Sensor placement: main sensor on an interior wall away from supply air and sunlight, add remote room sensors, supply and return temperature probes, and an outdoor sensor.

- Zoning and design: size zones by load, then apply Manual J, Manual S, and Manual D for equipment and duct correctness.

- Commissioning: confirm airflow, charge, control safeties, sequences, and calibration with logged readings.

- Robotics and diagnostics: use automated damper control, connected gauges, and continuous fault detection.

- Network and incentives: secure the controller on Wi Fi, enable firmware updates, and link to utility or solar interfaces.

- Maintenance: filters, coils, drain pans, software updates, and seasonal setpoint reviews.

Cost, Savings and ROI: Typical Energy, Maintenance and Payback Ranges

When controls and scheduling are dialed in, buildings typically see about 15 to 20 percent lower energy use. Predictive maintenance adds: roughly 25 to 30 percent lower maintenance spend, 20 to 40 percent longer equipment life, and 40 to 50 percent fewer unplanned outages. ROI is the yearly savings, energy plus upkeep and avoided downtime, divided by the upfront premium.

For context, stepping from a baseline SEER system to a higher SEER option often pushes cooling savings into the mid teens, which can stack with smart controls. In larger facilities, payback commonly lands between 1 and 5 years. Homes often take longer, but lifecycle value improves with longer life and fewer breakdowns. In our experience at Budget Heating (BudgetHeating.com), the best returns come from pairing right sized equipment with simple automation and a sensible maintenance plan.

Tradeoffs, Common Mistakes and When Automation Isn’t the Best Fit

We often see the same traps: bigger is better leads to short cycling, like a car in stop-and-go traffic, closing vents to save energy raises static pressure, and set-and-forget thermostats or constant fiddling both waste energy. Right-sizing, proper zoning, and scheduled maintenance beat gadgets alone.

- Oversized systems: automation cannot fix wrong capacity. The fix is proper load calculation and matched equipment, not more controls.

- Closed vents: trying to force air elsewhere stresses the blower. Use true zoning and balancing, not blocked grilles.

- Neglected filters and chaotic schedules: a smart thermostat cannot pull air through a clogged filter or smooth erratic setpoints. Follow a filter routine and use modest, consistent setbacks.

Not every space benefits from layers of automation. In small, uniform zones, simple, well tuned settings deliver similar results with less cost and complexity. If maintenance is overdue, start with filter changes and routine service before adding advanced controls.

How Climate, Codes and Refrigerant Rules Affect Automation Choices

In our 30 years of fielding systems across regions, the right automation depends on climate, codes, and refrigerant rules. Think of controls as cruise control that anticipates hills.

- Hot humid climates: prioritize latent removal with variable speed, dedicated dehumidification or reheat, and ventilation tied to demand.

- Hot dry climates: use economizers aggressively, supply-air temperature reset, and higher airflow for sensible load.

- Cold climates: manage balance point, stage heat pumps and auxiliary heat, optimize defrost, and add humidification control.

Codes like IECC, ASHRAE 90.1, and Title 24 drive DCV, economizer FDD, and supply-air reset. SEER2 minimums and test changes influence fan curves, staging, and setpoint strategies.

Under the AIM Act, newer refrigerants add safety requirements, often leak detection with automatic shutdown, ventilation, and alarms. Automation must integrate these interlocks and verify thresholds during commissioning.

Safety, Maintenance and Best Practices for Robotic Inspections and Automation

Homeowners can safely handle routine housekeeping: set thermostat schedules, replace or wash filters on the manufacturer’s cadence, keep supply and return vents clear by a few inches, and gently rinse debris from the outdoor coil with a garden hose while power is off at the disconnect. A filter is like a dust mask for your system, if it is clogged the equipment strains.

Call a licensed professional for anything involving electricity, refrigerant circuits, gas or oil combustion, internal mechanical repairs, control boards, and all robotic inspection or diagnostics. Robotics can reduce technician exposure to tight spaces, heights, and contaminants, but they must be operated by trained personnel who verify lockout, confirm confined-space safety, maintain line of sight, and keep clear of moving parts.

Do not open panels, bypass safeties, use pressure washers, or spray cleaners into equipment. Keep pets and bystanders clear during any inspection.

Conclusion and Next Steps: How to Start Evaluating HVAC Automation

HVAC robotics and automation pay off when done right: expect roughly 10 to 30 percent energy savings, fewer unplanned repairs, and longer asset life. The results hinge on clean integration, solid data, proper commissioning, cybersecurity, and real change management.

Treat automation as a structured asset management program: map your equipment, standardize tags and data streams, set performance baselines, commission to a written plan, assign owners for alarms and analytics, and embed cybersecurity and maintenance workflows.

Every site is different, and budget or legacy systems can complicate decisions. Our team has guided owners through this for 30+ years, and we can help you scope a pilot and right size hardware and software to your goals.

- Get a Custom Quote for controls, sensors, and retrofit automation

- Talk to Our Team by phone, U.S. based technical support from factory authorized pros

- Shop Controls and Smart Thermostats, wholesale pricing with free shipping on most systems and Affirm financing