HVAC Replacement for Commercial Buildings: Why this Guide Matters

This comprehensive guide is a vital resource for commercial property owners planning an HVAC replacement. It provides a clear, end-to-end overview, from initial considerations through final implementation, so you can make informed decisions that improve building performance, drive energy savings, and support occupant comfort and well being. An HVAC replacement is a strategic, long term investment, and success begins with a shared plan that connects system choices to operational goals.

Before comparing equipment, define goals and constraints. Treat this planning step like a blueprint that guides every decision:

- Comfort and humidity issues to resolve

- Indoor air quality targets

- Noise limits

- Energy and cost savings goals

- Decarbonization or electrification objectives

- Code and compliance needs

- Budget

- Timeline

Clarity on these points keeps the project focused, reduces surprises, and aligns outcomes with what matters most to your building and occupants.

Why Replace Your Commercial HVAC? Benefits, Risks, and Business Case

In the field, we see aging systems that still run but cost more each mile. Replacing a worn unit can improve comfort across zones, reduce energy use and operating costs, enhance indoor air quality, support occupant well-being, boost reliability, and align your building with evolving codes, standards, refrigerant rules, and broader sustainability goals.

Delaying replacement raises the odds of unplanned shutdowns, rising repair bills, and IAQ problems. It often erodes tenant and employee satisfaction and can lead to noncompliance with updated codes and refrigerant regulations, which introduces risk and potential penalties.

Signs Your Commercial HVAC Needs Replacement: Age, Performance and Repair History

When we qualify a replacement candidate, we start with a condition screen: age, repair history, IAQ complaints, energy spend, comfort issues, and capacity mismatches. Indicators include equipment in poor overall condition, repeat component failures, persistent odors or CO2 complaints, rising utility bills, and spaces that are chronically too hot or too cold under normal loads.

Document the facility and usage: building size and type, layout and zoning, envelope, hours of operation, occupancy patterns, internal or process loads, ventilation needs, and local design climate. Then assess the system and infrastructure: catalog system types, age, repair log, hot or cold spots, energy use, refrigerant type, controls or BMS, economizer or ERV status, and inspect ductwork, piping, condensate, gas lines, electrical service, roof structure, and service access. If several red flags align, plan a replacement study that matches building use and future growth.

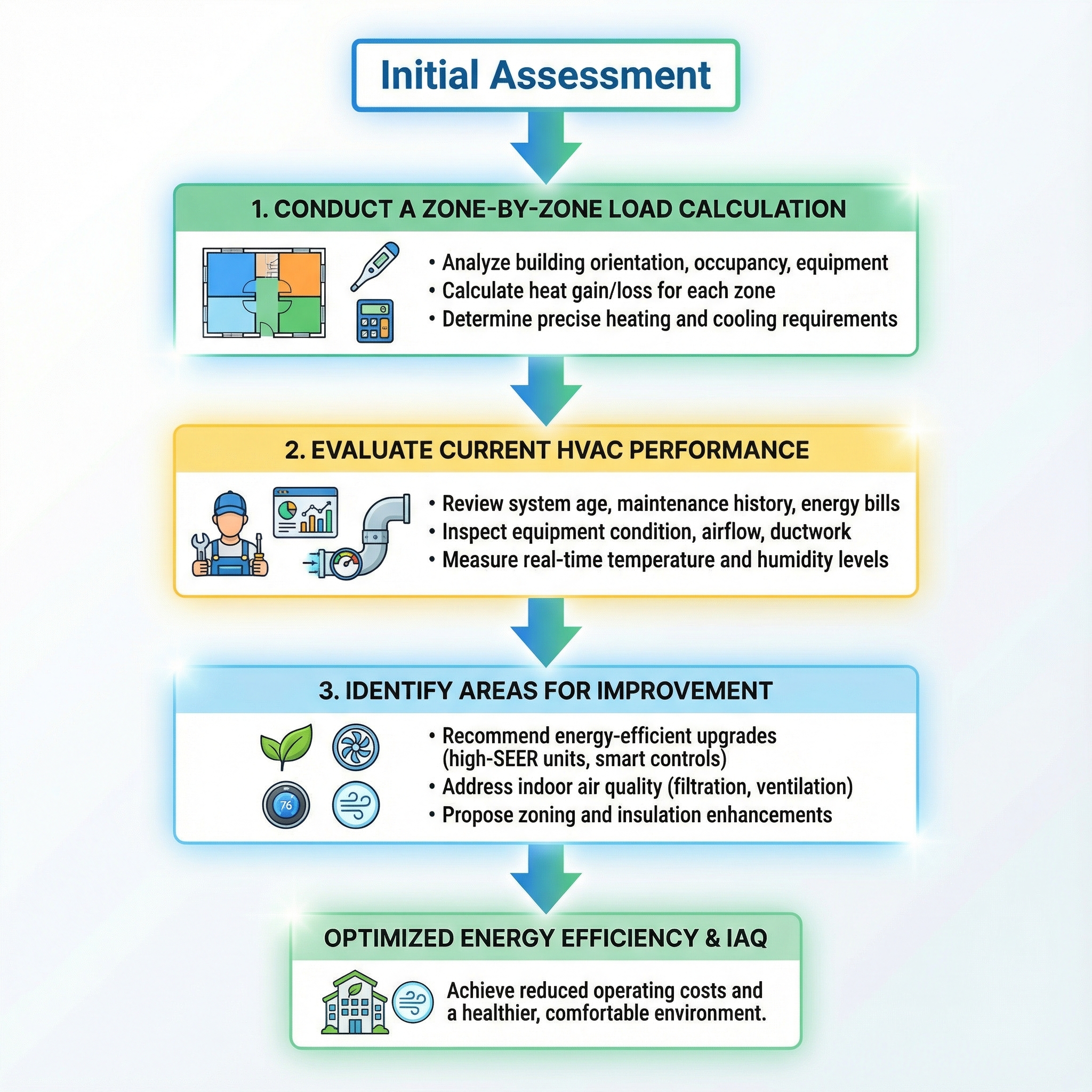

How to Assess Your Building's HVAC Needs: Load Calculations, Ventilation and Right Sizing

Right sizing starts with a formal load and ventilation calculation. We obtain zone by zone heating and cooling loads using ACCA Manual N or ASHRAE methods with local design weather data, not rules of thumb. A modest safety margin, typically 10% or less, is applied, then required outdoor air is documented per ASHRAE 62.1. It is like tailoring a suit, precise measurements beat guesswork every time.

Next, define thermal zones by use, schedule, and exposure, then select a distribution approach: VAV, VRF with heat recovery, or a DOAS paired with ERV or HRV. Evaluate demand controlled ventilation with CO2 sensing and economizer feasibility where climate allows.

- Ask for calculated peak loads by zone and the Manual N or ASHRAE load report.

- Confirm proposed model efficiencies and AHRI certificates.

- Detail duct modifications and target external static pressure.

- Review ventilation, economizer, and ERV control sequences.

- Define commissioning and TAB scope (testing, adjusting, balancing).

Controls, Commissioning and Maintenance: Ensuring Performance After Installation

Performance after install is set by controls, verification, and upkeep. We specify open-protocol controls that integrate with a BAS over BACnet, with scheduling, setpoint management, zoning, remote monitoring, and fault detection with analytics. Every proposal should include a written sequence of operations.

Commissioning should never be a box check. Require:

- Pre-functional checks on wiring, safeties, and sensors.

- Airflow and static pressure verification.

- Refrigerant charge confirmation.

- Economizer or ERV operation verification.

- Controls calibration.

- Independent TAB to confirm final CFM and outside air rates.

Before turnover, collect O&M manuals, wiring diagrams, startup sheets, control sequences, and warranty documents, and arrange staff training with an initial set of critical spares.

Set a preventive maintenance plan and IAQ targets, such as MERV 13 where feasible, with pressure drop accounted for. Evaluate UVGI or other air cleaners, and include humidification or dehumidification as needed. Track comfort, humidity, and utility bills against the pre-project baseline and push for corrections within the warranty window.

Types of Commercial HVAC Systems: Rooftop Units, Chillers, VRF and Packaged Options

Selecting and right sizing a commercial HVAC system starts with matching the system type to the building: size, climate, zoning needs, acoustics, space and weight limits, roof access, serviceability, and phasing constraints all matter.

- Rooftop Units (RTUs): Self contained packaged DX units mounted on the roof that supply ducted air. Best for low to mid rise buildings with adequate roof structure and clear crane access. Quick to install and simple to service. Confirm weight, curb layout, and noise limits for sensitive occupancies.

- Packaged or Split DX: Outdoor condenser with an indoor air handler, or a packaged unit on a ground pad. Useful when roofs cannot carry load or access is limited. Fits small to medium buildings with straightforward zoning and lower first cost goals.

- VRF or VRV Heat Pumps: One or more outdoor units feeding many indoor units via refrigerant piping. Excellent zoning and part load efficiency. Think of it like a volume knob for each zone. Requires careful refrigerant routing, condensate management, and indoor unit access.

- Chilled Water with Chillers: A central plant, air or water cooled, serving coils through piping. Favored for larger buildings, long runs, tighter acoustic targets, and heat recovery options. Higher initial cost, often competitive lifecycle cost with high annual hours.

- DOAS: A Dedicated Outdoor Air System that delivers code ventilation air and handles humidity, typically paired with VRF or chilled water for sensible cooling and heating.

Shortlist options by comparing lifecycle cost, structural capacity, service access, climate, and zoning. Geothermal heat pumps can be viable where land or well fields are available and long planning horizons justify drilling cost.

Retrofit vs Full Replacement: Costs, Lifecycle Tradeoffs and When Not to Replace

We rely on lifecycle cost and repair versus replace analysis, not sticker price. Options span like for like swaps with better efficiency and controls, phased upgrades, or shifts to high efficiency chillers, VRF or heat pumps, and advanced BAS.

- Equipment is fairly new with low repair costs and limited remaining life. Choose targeted repairs or add controls, economizers, or VFDs.

- Building is headed for renovation or demolition. Use temporary fixes or staged upgrades you can reuse.

- Very low annual run hours make payback long. Prioritize tune ups, commissioning, and controls.

Pitfalls we see: oversizing, SEER only decisions, expecting efficiency to cut bills without controls or commissioning, cloning old designs, skipping BAS or TAB, filter and vent myths, and ignoring refrigerant rules or logistics. Correctives: right sizing, BAS integration, full commissioning, and compliant refrigerants.

Energy Efficiency, Codes and Refrigerant Rules: SEER2, EER, IEER and Regional Requirements

Think of efficiency ratings like miles per gallon. SEER2 covers seasonal cooling for homes, HSPF2 measures heat pump heating, and commercial projects lean on EER for full load and IEER for part load. Higher values cut kWh and compressor runtime. IEER matters most because buildings spend most hours at part load, like using a dimmer instead of an on off switch. DOE test updates shifted the industry to SEER2, HSPF2 and EER2, with new commercial packaged unit minimums phasing in through 2029. In our experience at Budget Heating (BudgetHeating.com), designing to only today's code can complicate future replacements and bids as local amendments tighten and electrification expands with federal guidance.

- Verify IECC or ASHRAE 90.1 compliance plus local amendments.

- Match application to SEER2, EER or EER2, IEER, HSPF2 or AFUE.

- Plan for refrigerant phase downs that affect equipment choice and timing.

- Check utility incentives and tax credits before you buy.

Selecting a Contractor, Financing and Bid Evaluation: Getting the Best Lifecycle Value

Treat procurement like a project of its own: set a realistic budget, review financing options, and time the job to capture available incentives. Vet contractors carefully. Verify license, insurance, and manufacturer certification, ask for references, and insist on a written scope that covers demolition, crane or rigging, duct or piping, controls, TAB, commissioning, owner training, and final cleanup. In our experience at Budget Heating (BudgetHeating.com), clarity up front prevents costly change orders later.

- Apples to apples bids: require model numbers, capacities, efficiencies, accessories, filtration level, controls package, warranty terms, lead times, crane or rigging costs, commissioning and TAB scope, and year-one maintenance.

- Lifecycle cost model: total the capital cost, modeled energy use in kWh or therms, maintenance and consumables, and expected lifespan. Include incentives, then calculate ROI, simple payback, and NPV.

Choose the bid with the best lifecycle value, not just the lowest first price.

Project Roadmap & Next Steps: From Assessment to Commissioning and Ongoing Care

Replacing commercial HVAC is a strategic investment that improves comfort, lowers operating cost and emissions, and reduces risk. Start with an audit, formal load and ventilation calculations, and lifecycle cost analysis, coordinated early with qualified engineers and contractors.

Roadmap: assessment, design, procurement, installation, commissioning, then maintenance. Plan constructability and access, curb adapters, structural loading, clearances, crane plan, and noise or vibration mitigation. Confirm electrical readiness, voltage and phase, breaker sizing, disconnects, surge protection, panel capacity, and demand charges. Phase the install to limit downtime, provide temporary conditioning, communicate with occupants, and manage safety. Close with proper refrigerant recovery, recycling, roof repairs, and disposal manifests.

We know timelines and budgets are tight, and our 30+ years in HVAC let us turn this into a predictable plan and an accurate quote.

- Get a Custom Quote

- Talk to Our Team, U.S.-based phone support

- Shop Commercial HVAC, many items ship free, financing with Affirm