Why Florida Winters Matter for HVAC Planning: Scope and Purpose

Florida's winters are short and generally mild, yet a handful of cold snaps can upset comfort, efficiency, and reliability. In our experience, those brief dips are when systems are most tested, so planning for them pays off far more than planning for an average day.

This project uses historical climate records, building energy use, and operational data to characterize Florida's winter conditions, then builds predictive models to support HVAC decisions. The goal is simple: translate real-world patterns into practical guidance so equipment and controls perform predictably when temperatures swing.

What you will get from this guide:

- A clear scope for Florida's winter profile and why it matters even in a warm state.

- How historical data and predictive modeling work together to reduce uncertainty in HVAC planning.

- Decision-ready insights that help align comfort, efficiency, and reliability during cold snaps.

Think of it like tuning a car for the few steep hills on an otherwise flat road. The hills define the limits, and smart planning makes the whole trip smoother.

Florida Winter Climate Overview: Typical Conditions, Microclimates, and Regulatory Context

Florida is hot and humid with generally mild winters, yet conditions are not uniform. North to south, and coast to interior, microclimates shift HVAC risk. Salt air, wind exposure, daily temperature swings, and urban density change how equipment lasts and performs.

Microclimate variability matters. Coastal sites face corrosion, so corrosion-resistant materials and finishes help. Interior areas tend to see wider day to night swings, and urban heat islands keep nights warmer than open suburbs. Within this context, DOE and ASHRAE baselines and Florida Building Code guide choices for placement, ventilation, defrost, and condensate handling.

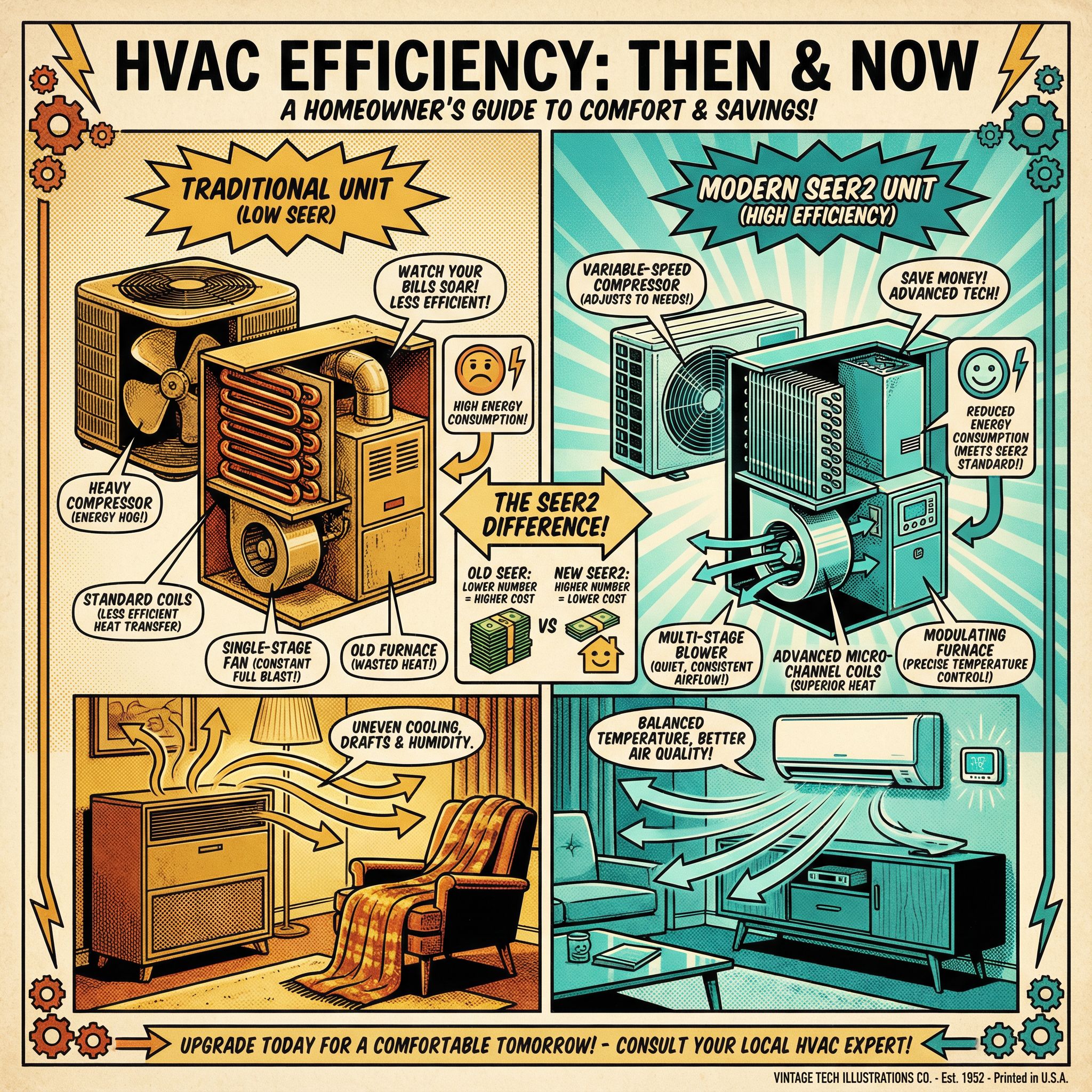

Key Metrics for HVAC Planning: SEER/HSPF, Degree Days, and Peak Temperatures

SEER and SEER2 measure seasonal cooling efficiency. In the Southeast, current minimums are 14.3 SEER2 for most split systems under 45k Btu and 13.8 SEER2 for larger units. SEER2 maps to legacy SEER at about 5 percent lower numerically. In Florida, where cooling dominates, moving from 14.3 to 16 or 18 SEER2 can trim summer kWh roughly 10 to 20 percent. HSPF rates heat pump heating; our mild winters mean it matters, but less than SEER2.

For load forecasting, degree days are key: Cooling Degree Days and Heating Degree Days total how far, and how long, outdoor temps stray from a 65 F base, like an odometer for weather load. Pair that with local peak design temperature and humidity to size capacity and choose controls, such as two stage or variable speed. In our experience at Budget Heating (BudgetHeating.com), these metrics prevent oversizing and reduce lifetime cost.

Costs, Savings and Modeling Trade-offs: Interpreting Lifecycle Impacts

For Florida homes, upgrading to a modern SEER2 unit typically trims cooling energy about 8 to 10 percent versus a recent baseline, which translates to about 120 to 300 dollars in annual bill savings for most households. Moving from a very old system to a current SEER2 model delivers a larger step change, often meaningfully higher than that 8 to 10 percent. In our experience at Budget Heating (BudgetHeating.com), payback is usually measured in years, not decades, because of long cooling seasons and high runtime.

To model lifecycle impacts, align the upgrade with your planning horizon. Short horizons favor lower upfront cost with modest efficiency gains. Longer horizons capture cumulative savings and reduced risk from outages. Build scenarios with your past 12 months of bills, expected runtime, and the SEER2 improvement. Then test conservative and optimistic cases to bracket outcomes. Think of it like choosing tires: daily miles and road conditions determine whether standard or premium rubber makes financial sense over the miles you actually drive.

Common Myths and Trade-offs: When Predictive Planning Isn't the Right Tool

Predictive planning helps, but it is not a cure all. Common myths we still see: Florida never gets cold, oversizing cools faster, and big setpoint swings save money. In practice, cold snaps happen, right sizing manages humidity, and large swings raise runtime and discomfort.

- Intermittent cabins or short term rentals: simple programmable controls and fixed humidity targets often beat complex prediction.

- Leaky ducts or weak insulation: seal, balance, and do a load calculation first. Prediction cannot mask losses.

- Unreliable internet or power: use basic staging or steady setpoints. Prediction needs clean, stable data.

Aim for moderate setbacks, proper airflow, and dedicated dehumidification when needed.

From Weather to Decisions: What Predictive Models Enable for HVAC Operators

Predictive models turn weather history and forecasts into clear HVAC decisions. With advance notice, we plan settings and service rather than react.

- Cold snap operations: preheat ahead of the front, use modest setbacks, and apply auxiliary heat lockouts to avoid bill shock and protect equipment.

- Mild winter strategy: right-sizing guidance and thermostat schedules that match expected loads to keep comfort steady without overrun.

- Resilience and upkeep: predictive alerts for maintenance, targeted weatherization where losses will be highest, plus smart staging and zone prioritization when temperatures dip.

Homeowner & Facility Checklist: Preparing Equipment Before a Florida Cold Snap

Florida heat pumps handle light chills well, but short hard freezes lean on electric strips. We have seen most problems come from simple misses. Use this time phased list.

- Pre season: Replace filter MERV 8 to 11, seal obvious duct leaks, clear 18 inches around the outdoor unit, label and verify breakers, confirm thermostat Heat mode and aux settings, set indoor humidity 45 to 50 percent, ensure defrost water drains away from walkways.

- 48-72 hours before: Trigger: forecast below 38 F for 4+ hours. Do a 10 minute check: set Heat, raise 3 F, verify warm supply air 90 to 110 F, Aux or Heat Strip indicator comes on, test Emergency Heat for 3 to 5 minutes, remove leaves from the outdoor coil, confirm disconnect is fully seated.

- During event: Avoid big setbacks, keep fan on Auto, run ceiling fans low clockwise, let defrost finish, do not block returns, avoid space heaters on shared circuits.

- Post event: Inspect and replace a dark filter, check for tripped breakers, reset humidity near 50 percent, note unusual smells or repeated aux runtime for follow up.

Safety, Maintenance and When to Call a Professional

In our experience, homeowners can handle light upkeep: replace or wash filters regularly, clear leaves and grass from the outdoor unit, and check thermostat settings or batteries. Always shut off power at the disconnect or breaker before opening any panel.

We draw the line at anything involving refrigerant, electrical diagnostics or repairs, or any gas and combustion work. The refrigerant loop is a sealed system, like a bloodstream, and DIY opening can cause injury, damage, and void warranties.

Tools, Libraries, and an Implementation Roadmap for Predictive HVAC

In practice we move data to decisions in five steps: connect, store, model, deploy, monitor. Ingest BAS feeds via BACnet, Modbus, or MQTT into Kafka, then InfluxDB or TimescaleDB. Cloud paths include AWS IoT to Timestream or Azure IoT Hub to Data Explorer. Orchestrate with Airflow, validate with Great Expectations. Build features in pandas or Feast. Train with scikit-learn, XGBoost, or PyTorch, track in MLflow. Serve with Docker and FastAPI on Kubernetes. Monitor drift with Prometheus, Grafana, Evidently.

Balancing Historical Insights with Predictive Models: Recommendations and Next Steps

Florida winters are low load, yet variable. Use a combined modeling strategy: time series for the baseline, ML for nonlinear building and weather effects, plus ensemble, probabilistic runs for extremes. Validate with rolling backtests, retrain after cold snaps, and plan scenarios for peaks.

We know you are balancing comfort and budget in a variable climate. Operationally, right size equipment, tighten controls, improve the envelope, and stay demand response ready. Our team has 30+ years doing this in the field.

Ready to turn forecasts into action? We can map the path in one call.

- Get a Custom Quote

- Talk to Our Team by phone for fast U.S. based support

- Shop Heat Pumps and Controls at wholesale pricing, many items ship free, financing with Affirm