Why Comprehensive HVAC Training and Development Matters Today

Heating, ventilation, and air conditioning shape comfort, energy use, and equipment life. In our field experience, the programs that work blend classroom instruction, hands-on labs, manufacturer modules, and e-learning, so technicians deliver safe, efficient, and reliable results. Who benefits: apprentices, seasoned techs, installers, sales, and managers. Expected outcomes: fewer callbacks, faster diagnostics, code compliance, better first-time fix rates, and longer equipment life.

Start Right: Assessing Training Needs with Competency Gap Analysis

Competency gap analysis gives operations managers a clear picture of who can do what today, what is mission critical tomorrow, and where training dollars will actually move the needle. Start by listing core domains that every tech must master: refrigeration cycle, electrical, and airflow. Layer in diagnostics, documentation and time management, soft skills, digital tool use, and compliance.

Build a competency matrix that maps each domain to levels and sign off criteria. For example: Novice, Assisted, Independent, Mentor. Tie each level to observable outcomes, such as measuring superheat and subcool correctly, interpreting wiring diagrams, verifying airflow with static pressure, and documenting findings. Sign off should be evidence based, using checklists, quizzes, ride along observations, time to-diagnose targets, and low callback thresholds.

Skill sticks through repetition. Plan repetition driven mastery by scheduling repeated, supervised exposure on real jobs, plus mentorship and ride alongs to transfer tacit knowledge. Set rep targets per task across different equipment types and fault conditions, so techs do not just recognize one pattern, they learn the diagnostic framework.

- Standardized SOPs and checklists reduce variability and callbacks.

- Certifications and code compliance lower risk and rework.

- Continuing education keeps new tech efficient and safe.

- Soft skills improve first visit resolution and customer rapport.

- KPIs align quality assurance with training, not just production.

- Cross training and design literacy improve system level decisions.

- Digital tool and data literacy turns readings into clear actions.

- Defined career paths strengthen retention and bench depth.

Prioritize modules where gaps are widest and business impact is highest, such as universal diagnostics and airflow verification before niche controls.

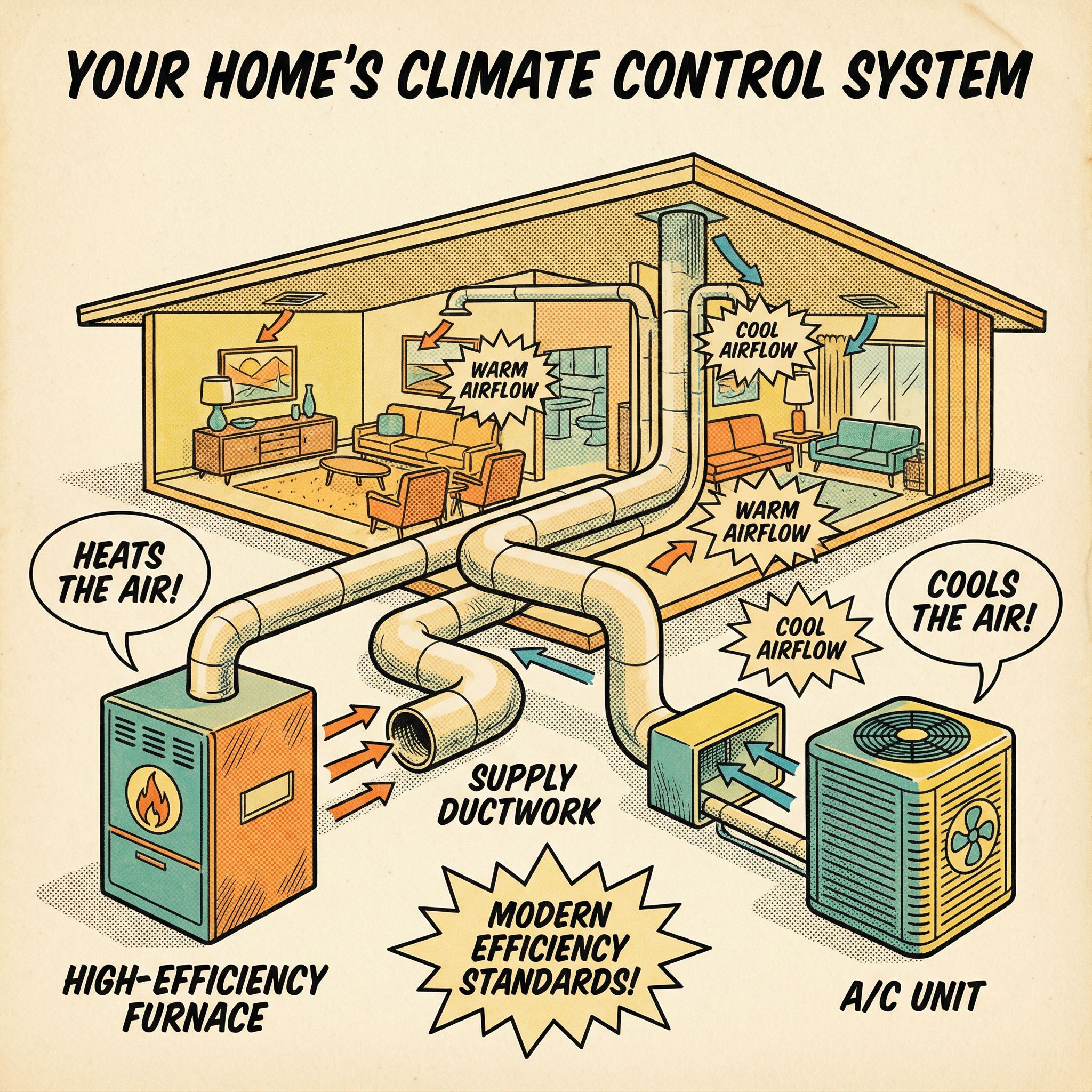

Core Technical Curriculum: HVAC, Refrigeration, Controls and Efficiency Standards

Teach refrigeration, electrical safety, airflow and duct design, combustion safety, controls, and commissioning. Verify superheat, subcooling, static pressure, gas input, and sequences. Static pressure is ductwork's blood pressure, too high and performance drops.

- "Top-offs" mask leaks, find and fix.

- Oversizing causes short cycles and poor humidity.

- Match filter MERV to blower and ducts.

- Closing vents raises pressure, not savings.

- No DIY on electrical or combustion.

- Continuous fan can add humidity in some climates.

- Duct cleaning is limited, seal leaks first.

SEER is seasonal efficiency. SEER2 uses a tougher test with higher external static, so numbers read lower, not less efficient. Regional minimums changed in 2023. Verify compliance and matchups with EnergyGuide and AHRI, then translate SEER gaps to utility dollars. In our experience at Budget Heating (BudgetHeating.com), install quality and duct pressure determine real-world results.

Tradeoffs and Real-World Limits: When Training Isn't the Whole Answer

Training improves consistency and speed, often cutting callbacks and trimming hours per job. For ROI, tie efficiency upgrades to energy use: a change from 14 to 16 SEER or SEER2 roughly equals about 14 percent less cooling energy, all else equal. Simple payback is straightforward: extra equipment cost divided by annual savings gives years to break even. Remember the swing factors that move the math: climate hours, duct leakage, and installation quality.

- Chronic comfort issues from bad duct layout or major leakage: training helps diagnosis, but redesign, sealing, or balancing fixes the root problem. A leaky system is a bucket with holes, not a training gap.

- Mild climates with low runtime: paying a large premium for a higher SEER may yield a long payback. In these cases, prioritize duct sealing, controls, or right-sizing before chasing peak ratings.

- Repeat quality misses due to process gaps or tools: standard commissioning checklists, calibrated gauges, and static pressure testing often outperform more classes alone.

Set expectations accordingly: invest in targeted upskilling where it shortens jobs and reduces returns, and pair it with hardware, process, and design fixes where those deliver faster, clearer ROI.

Assessment, Competency-Based Evaluations and Measuring Effectiveness

From years in the field, we find a competency-based approach paired with repetition-driven mastery keeps training objective. Use role-specific skills checklists for diagnostics, brazing, evacuation, charging, airflow, controls, and full commissioning. Validate with practical exams on rigs or live jobs. During ride-alongs, supervisors provide step-by-step sign-offs before solo work.

- First-time fix rate

- Callback rate

- Safety observations and incident frequency

- Average ticket per job

- Commissioning completeness score

Safety, Maintenance and Customer-Facing Standards: Boundaries and Best Practices

Safety runs from training to every visit. Homeowners change filters, keep 2 ft condenser clearance, and test thermostats. Licensed pros handle refrigerant diagnostics, electrical work, combustion checks, and commissioning. Techs should state these limits up front and explain the preventive plan.

- Indoor: filter condition, clear drain, blower and static pressure, coil or heat exchanger, safeties.

- Outdoor: clean coil, check clearances, fan amps, capacitors, contactor, confirm charge by superheat/subcooling.

- Systemwide: de-energized tightening, control tests, baseline readings.

- Safety and training: never release refrigerant, never work in live panels, report gas or CO, train with code, OEM guidance, labs, fault sims, lockout tagout.

Regional, Regulatory and Climate Considerations for Program Design

Training must match the map, like choosing tires for snow or desert. With SEER2 in 2023 and DOE's North, Southeast and Southwest regions, minimums and allowable models differ. Teach techs to read the condenser label, verify regional SEER2, and document it before permits or startup. In our experience at Budget Heating (BudgetHeating.com), crews that do this quick check avoid red tags and returns.

- North: freeze protection, condensate routing, defrost checks, right sizing for long shoulder seasons.

- Southeast: dehumidification strategy, airflow settings, tight ducts, reliable drains to control latent load.

- Southwest: high sensible design, coil clearance and sun exposure management, balanced airflow to keep capacity steady.

Delivery Models: Blended Learning, Apprenticeships, VR and On-the-Job Coaching

Effective HVAC training uses the right mix, not a single method. We combine instructor-led classes for codes, safety and core theory, e-learning for product specifics and procedures, microlearning for quick refreshers, VR or simulators for low-risk practice, and on-the-job apprenticeships and ride-alongs for live application.

Our blended model layers these steps: brief classroom kickoff, assigned e-learning prework, simulator or VR labs, structured ride-alongs with checklists, then targeted microlearning and an instructor review. Skill sign-offs tie back to the competency matrix.

To scale: small shops run a quarterly class, curated e-learning, and one mentor ride-along per key task. Mid-size teams add monthly simulator blocks and peer coaching rounds. Enterprise programs standardize national e-learning, regional lab days, and local field coaching with consistent assessment artifacts.

Retention, Career Ladders and Partnerships: Making Training Stick

Retention grows when people see a path. We map ladders from helper to senior specialist, with pay bands tied to milestones in the competency matrix and QA KPIs. Mentoring pairs new hires with vetted leads for ride-alongs, brazing refreshers, and post-job debriefs. Incentives include paid exam fees, study time, tool stipends, and wage bumps for NATE, EPA 608, and manufacturer certs. We partner with trade schools, manufacturers, and RTOs for pipelines and accredited modules. Budget long term: per-tech spend, LMS integration, reporting, seat bundles, SLAs, and train-the-trainer support.

Putting It All Together: A Practical Roadmap to Build Your HVAC Training Program

The takeaway: a durable program blends ongoing technical education, field experience, soft skills, and clear career paths. Roadmap: 90 day pilot with one crew, baseline the competency matrix, deliver blended learning, and track certifications. Hold biweekly reviews, then scale in three waves while updating content for controls, IoT, and low GWP refrigerants. Set a quarterly evaluation cadence, refresh IDPs, and keep school and manufacturer partners engaged.

We know building this takes time. With 30+ years in HVAC and U.S. based phone support, our team can align training with the equipment you deploy.

- Get a Custom Quote

- Talk to Our Team by phone

- Shop Heat Pumps and Ductless Mini Splits