Commercial HVAC Maintenance: Why Every Business Needs a Proactive Plan

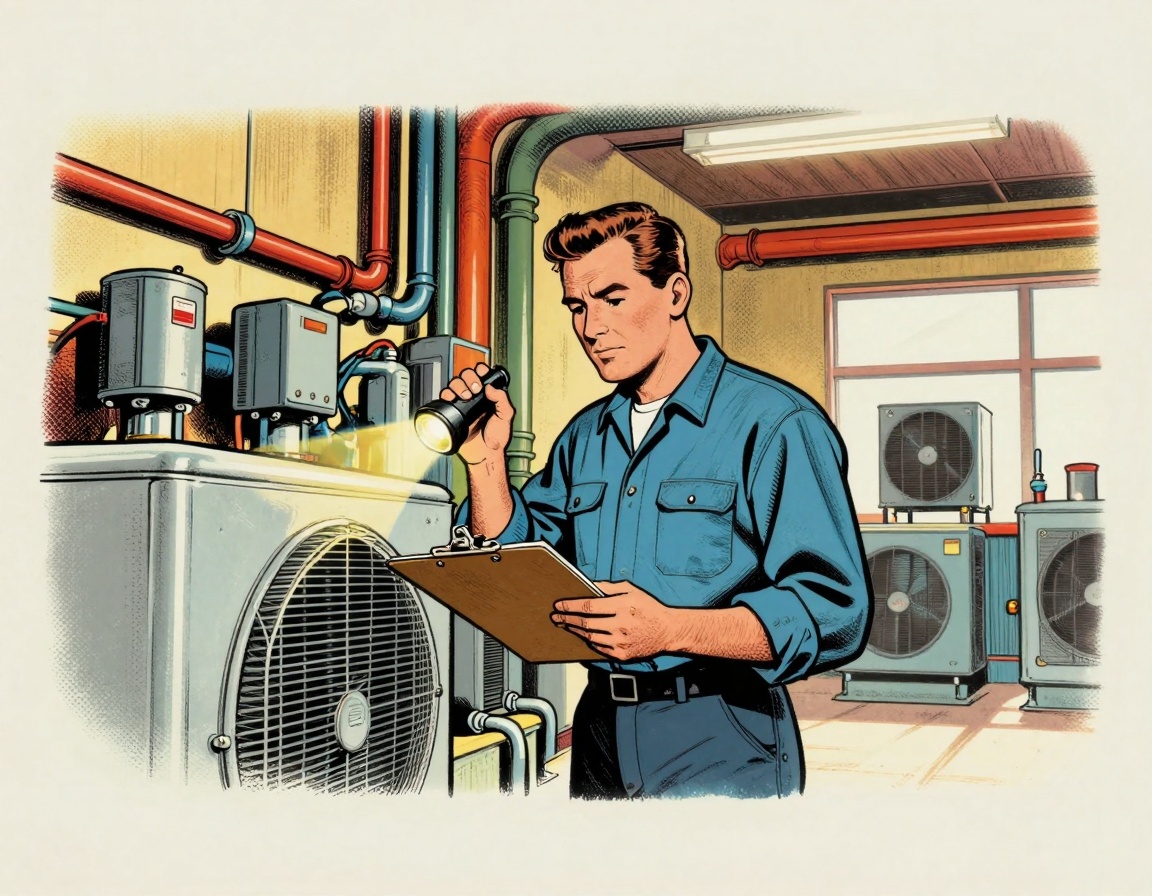

HVAC drives comfort, uptime, and energy costs in every commercial building. A proactive plan keeps staff productive, customers comfortable, indoor air quality steady, and breakdowns rare, while controlling energy bills, often the largest facility expense. In this guide, we share what works: servicing filters, coils, belts, electrical connections, refrigerant levels, thermostats, and ductwork, with cleaning and calibration that improve efficiency. Expect clear steps to build a preventive schedule with your service provider, extend life to 15 to 20 years, spot warning signs, and use a simple checklist to cut downtime.

What This Guide Covers: A Practical, Business-Focused Approach to Commercial HVAC

This guide is for property owners, facility managers, and business decision-makers who need HVAC that is reliable, efficient, and compliant without guesswork. We focus on actions you can schedule and track, not theory. You will find clear explanations of major system components, routine and seasonal maintenance tasks, inspection schedules, and recordkeeping that ties costs to performance. We also cover energy efficiency measures, regulatory and indoor air quality essentials, how to select and manage contractors, realistic budgeting, and emergency response planning. Think of it as a playbook to reduce downtime, control spend, and protect occupant comfort.

Why Regular Commercial HVAC Maintenance Matters: Reliability, Comfort and Cost Control

Commercial HVAC systems are like a chain: hundreds of parts move together, and one weak link, a dirty filter or loose connection, can snowball into higher energy use, uneven comfort, and failures. Proactive maintenance stops small issues before they grow, often adding 5 or more years of service life while protecting uptime, air quality, and predictable costs. In our experience at Budget Heating (BudgetHeating.com), structured programs keep operations steady.

- Lower energy bills: clean filters and coils, correct charge, tight connections cut waste, about 10 to 40%.

- Fewer breakdowns: inspections catch wear, electrical issues, and drainage problems early.

- Longer life and reliability: seasonal cleaning, lubrication, and adjustments reduce stress and extend service life.

- Better IAQ and comfort: filter swaps and coil cleaning steady airflow, particulates, temperature, and humidity.

- Smarter budgeting: a CMMS schedules tasks, logs findings, and informs repair, retrofit, or replacement.

Maintenance Frequency & Checklist: Daily, Monthly, Seasonal and Annual Tasks

Build a multi-tier maintenance program that assigns quick checks to operators, routine care to facility staff, and deep service to qualified technicians. Think layers of care, from daily tidying to scheduled expert visits.

- Daily to weekly: Monitor space temperatures and thermostat settings, verify equipment is running as expected, listen for alarms or unusual noise, and note anomalies.

- Monthly to quarterly: Replace or clean air filters on a cadence that matches occupancy and dust load, perform visual checks and light cleaning, and log readings in your CMMS.

- Seasonal: Before cooling and heating seasons, confirm control sequences and economizer operation, prepare both modes, and schedule professional tune ups.

- Semiannual to annual: Arrange qualified technicians at least twice per year for electrical, refrigerant, combustion, and deep clean tasks, then document findings and corrective actions.

In our experience at Budget Heating (BudgetHeating.com), teams that track schedules, work orders, and performance trends in a CMMS catch small issues early and reduce surprise outages.

Energy-Saving Upgrades: Controls, Economizers and Variable-Speed Drives

SEER and SEER2 measure seasonal cooling efficiency, with SEER2 the 2023 test update, so compare like-for-like. Legacy systems often run 10-14 SEER, current baselines are mid-teens, and upper-teens go higher. Moving from 14 to 16 SEER typically cuts cooling electricity by about 12-15%. Ratings are only sustained with clean coils, correct charge and verified control operation.

- Controls: tighten schedules, setpoints and ventilation to reduce runtime.

- Economizers: use cool, dry outdoor air to offset compressor hours where climate allows.

- Variable-speed drives: modulate fans to match load, cutting part-load power.

- Prioritize high-hour equipment first; in regions with EER2 or stricter minimums, select accordingly.

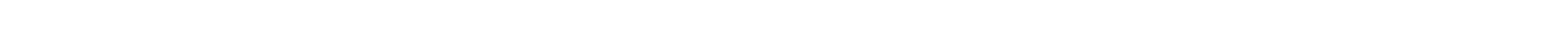

Safety, Roles and What Your Team Can (and Shouldn't) Do In-House

We draw a simple line: your team handles light care, licensed techs handle diagnostics and repairs. In-house, do daily or weekly visual rounds for noise, blocked vents and water near air handlers, verify thermostats, clear leaves from outdoor condensers, wipe grilles, inspect filters monthly and replace as needed, clean condensate pans and flush drains. Log zone temps, comfort complaints, energy and alarms in a CMMS and flag trends.

Call a licensed pro for refrigerant work, electrical diagnostics, combustion equipment, safety controls, deep internal cleaning or mechanical repairs, or persistent short cycling, tripped breakers, odors or energy spikes. Safety first: de-energize and lockout/tagout, do not open panels or sealed refrigerant circuits without licensing and PPE, avoid high-pressure coil washing, keep combustibles away, document all work. Schedule biannual professional inspections.

Costs, Savings and Typical ROI: What Affects HVAC Operating and Replacement Costs

We typically see HVAC account for about 39% of a facility's energy use, so small efficiency gains move the needle. Routine maintenance, cleaning coils and calibrating airflow, often cuts energy 10 to 40% compared with neglected systems. Smart controls and optimization, advanced scheduling, occupancy and sensor-driven ventilation, can deliver roughly 20 to 50% when paired with maintenance and basic monitoring. Think of it like clearing a clogged dryer lint screen, the system breathes easier and runs cheaper.

- Controls retrofits with VFDs and sensors: about 15 to 25% savings.

- Older systems, roughly 10+ years: modern high efficiency equipment yields 20 to 40% annual savings.

- Full replacements with high efficiency units plus proper commissioning: around 30 to 50% savings.

Across these strategies, we see typical payback windows in the 3 to 5 year range, depending on energy price, hours of use, and local climate.

Preventive vs. Reactive Maintenance: Honest Tradeoffs, Myths and When Replacement Is Better

Reactive fixes raise costs and shorten life. Myths: wait until it breaks, bigger is better, filters can wait, refrigerant needs annual top offs, high efficiency needs no service. In our field work, sealed circuits require leak repair, correct sizing and airflow, plus periodic cleaning and calibration. Maintenance is not enough at 10 plus years with repeat failures, in dusty or corrosive sites, or with bad sizing and controls. In those cases, replacement, controls retrofits, or specialty filtration work better than serial repairs.

Compliance & Standards: DOE 2023 Rules, Regional Minimums and Local Code Considerations

In 2023 the DOE moved the industry to SEER2, EER2 and HSPF2 and tied compliance to regional minimums for split systems. Think speed limits that change by state: the Northern region sits around a 13.4 SEER2 baseline, while the Southeast and Southwest require higher SEER2 and certain EER2 thresholds, depending on capacity. It is illegal to sell or install equipment below your region's minimums, so verify nameplate SEER2, EER2 and HSPF2 before replacement. Local codes can add layers, for example California Title 24 may expect documented maintenance. We see smoother inspections when owners keep dated records of filter changes, coil cleaning, refrigerant checks, thermostat and control validation, plus seasonal prep. Pair those region-agnostic practices with your jurisdiction's specific requirements to stay compliant and avoid penalties.

Next Steps: Build Your Facility's HVAC Maintenance Program

Regular, proactive maintenance protects comfort, IAQ, compliance, and asset value at the lowest total cost. Document it in a CMMS with asset tags, checklists, photos, and reminders, assign daily logs to staff, schedule contractor tune-ups, and keep an emergency playbook with vendor contacts, spare filters and belts, rental options, and a capital reserve of roughly 3 to 5 percent per year.

We get that facilities juggle uptime, budgets, and approvals.

With 30+ years in HVAC and U.S.-based support, we can turn this into a right-sized program and equipment list.

- Get a Custom Quote

- Talk to Our Team by phone or chat

- Shop Commercial Equipment