Beyond the Lab: Why UV C Is Moving into Real World HVAC

Ultraviolet (UV C) is moving from controlled tests into everyday HVAC, installed inside air handlers and ducts where it targets coils and drain pans for germicidal and cleanliness benefits. From decades in the field, we see the practical results decision makers care about: steadier airflow, fewer musty smells, some reduction in microbial bioburden, more consistent comfort, and cleaner coils that can lower energy use and extend equipment life. This piece stays beyond the lab, how and where lamps are mounted, what results are realistic, and how UV integrates with filtration and ventilation so you can decide if it fits your system.

How UV C and UVGI Work in HVAC Systems: The Science You Need to Design For

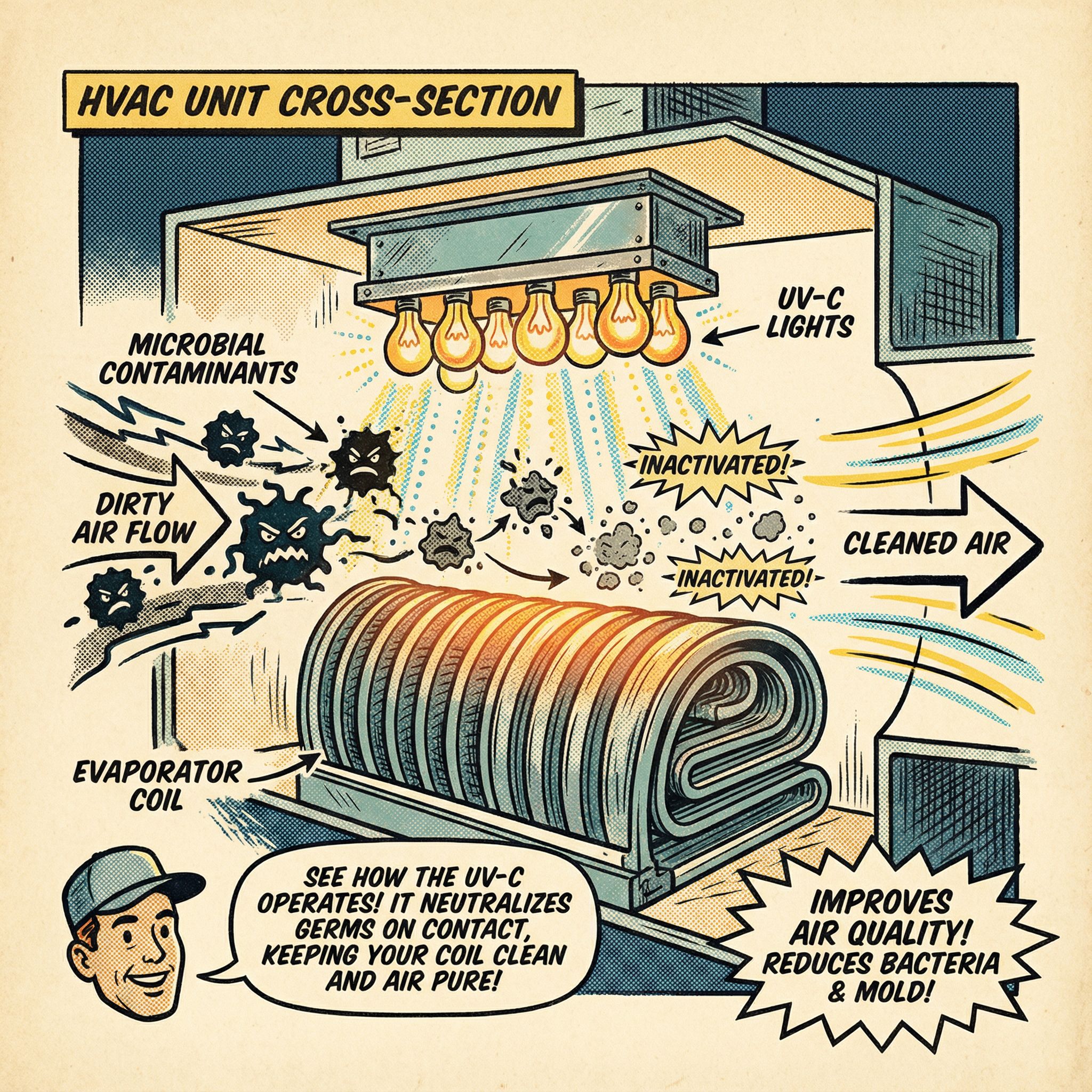

UVGI uses germicidal UV C to damage microbial DNA or RNA, inactivating many bacteria, molds, and some viruses in air or on coils. The governing variable is dose, irradiance times exposure time, like sunburn where intensity and time both matter.

In the field, success comes from design. We calculate irradiance at the target and account for airflow and dwell time, lamp placement, shadowing, surface reflectivity, humidity, surface soil, and lamp aging; otherwise lab wins will not translate in buildings.

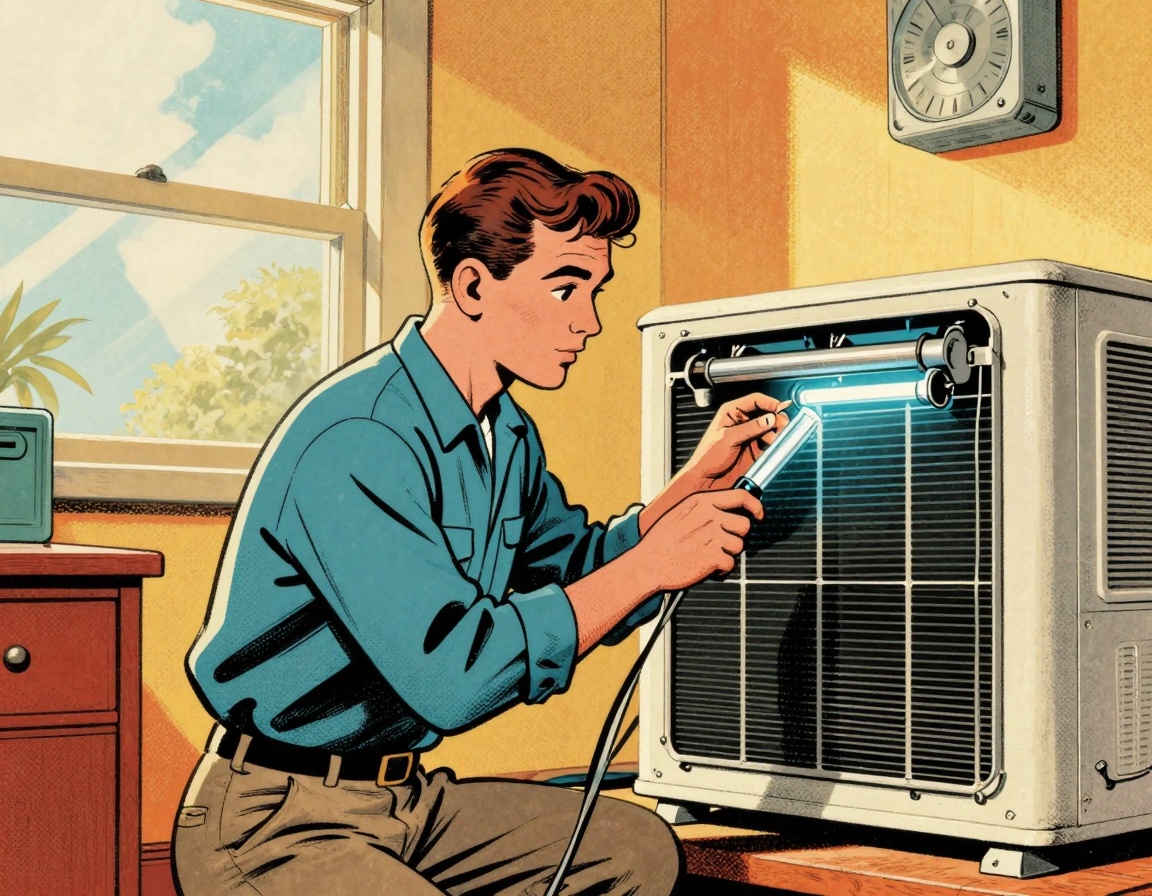

Where UV Gets Installed: Coil, In Duct and Upper Room UV Applications

In our installs, UV in HVAC falls into three buckets: coil surface irradiation that keeps evaporator coils and drain pans clean, in duct UV that targets airborne microbes in the duct airstream, and upper room UVGI used in occupied spaces to disinfect air as it circulates through an upper zone. Choose configuration by goal, coil hygiene, in airstream disinfection, or both. Layout, budget, and access often decide what is practical. Think of UV like paint, it only works where the light hits.

- Provide clear line of sight to the full coil face and pan, or to the moving airstream.

- Minimize shadow zones with strategic lamp placement and reflectors.

- Shield nearby wiring, plastics, and controls from direct UV exposure.

UV is also used in portable air purifiers and in surface or water systems, all of which depend on correct dosing, safety, and maintenance.

Key Benefits of UV in HVAC: Cleaner Coils, Better IAQ and Potential Energy Gains

UV lights focus on the grimiest part of the system: the evaporator coil and drain pan. By suppressing biofilm and microbial growth, fins stay open, heat transfer stays efficient, and airflow remains steady. Slime and musty odors fade. It is like a quiet self-cleaning cycle for your air handler that runs every day. In our experience at Budget Heating (BudgetHeating.com), systems with UV maintain steadier airflow between cleanings.

- Less visible biofilm on coils and pans

- Reduced mildew and musty odors

- Cleaner air-handler interior

- More consistent comfort and near-rated efficiency over time

UV is a layer in an overall IAQ plan. It targets microbial contaminants and, in some configurations, can lower airborne bioburden, but it does not remove dust or gases. Clean coils also support energy gains. Real installations report savings up to about 35% in favorable cases, and a 2018 study measured roughly 15% when UVGI was paired with electrostatic filtration versus conventional filtration alone. Actual savings vary by site and baseline coil condition.

Tradeoffs & Limitations: When UV Is Not the Right Choice (And Better Alternatives)

UV is not a cure-all. Think of it as a disinfecting light, not a vacuum. It does not remove dust, smoke, VOCs, or gases, and results depend on correct placement, dose, and upkeep. Properly designed systems are safe, and installations must meet applicable codes and standards. It is also not set and forget: lamps soil and output declines, so cleaning and timely replacement are required.

- High particulates or VOCs: prioritize MERV or HEPA filtration plus ventilation or source control.

- Limited coil or duct access or unavoidable shadowing: use portable air cleaners or schedule mechanical coil cleaning.

- Material sensitivity or strict ozone limits: select non-ozone lamps or choose non-UV solutions.

Lab Results vs. Field Performance: Why Controlled Studies Don't Always Predict On Site Outcomes

In controlled chambers, microbial knockdown looks impressive. In field deployments we see that success does not automatically carry over, because the delivered dose depends on on-site irradiance and exposure, not a catalog rating. Real systems add variables that shift outcomes.

- Access that dictates lamp placement and sight lines

- Actual airflow and dwell time across the irradiated zone

- Surface film or coil fouling that shields microbes

- Space humidity that affects survival and UV absorption

Closing the gap means translating lab dose data into site-specific irradiance and exposure calculations, then validating on site. Measure air volume and velocity, confirm lamp-to-target distance, and verify results after commissioning rather than assuming laboratory numbers will appear.

Where UV Delivers the Most Value: Climate, Building Type and System Baselines

UV does not change nameplate SEER or SEER2, but it is often paired with modern high SEER systems to help preserve the efficiency you paid for by keeping coils and drain pans clean. In hot humid regions, long cooling seasons and persistently wet coils make UV a high value add, limiting mold and biofilm that choke airflow. In hot dry areas, biofilm is less pronounced, yet UV still supports indoor air quality and helps coils resist dust and film. Cooler, heating dominated regions use UV to maintain seasonal cooling performance during shorter cooling windows and to prevent musty starts after idle periods.

- Hospitals and schools: hygiene, odor control, stable airflow.

- Office buildings: fewer odor complaints and steadier comfort.

- Multi family: shared equipment benefits from cleaner coils.

- Industrial sites: process odors and contaminated airstreams.

Think of UV like a toothbrush for wet coils, keeping heat transfer and airflow consistent over time.

Design & Integration: Sizing, Placement, Safety and Code Compliance

Treat UV like any other engineered accessory: design, verify, document. Start with a licensed HVAC contractor assessment that reviews coil size and location, duct access, filtration, electrical availability and cabinet constraints that affect lamp placement.

- Equipment specification: select HVAC rated UV C with documented germicidal wavelengths, UL or ETL listings and ozone free operation per data sheets, not marketing claims.

- Sizing and spec: determine lamp count and output for the coil face area or duct dimensions, estimate dose at the target and plan for shadow zones.

- Filtration and warranty: coordinate with MERV 8 to 13 filtration as the system permits, verify UV will not void equipment warranties and confirm material compatibility.

- Power and operation modes: confirm a suitable power source and define whether lamps run continuously or coordinate with the blower per manufacturer guidance.

- Standards and codes: align with relevant standards and local codes, for example ASHRAE guidance and ASHRAE 189.1 where applicable, and include required documentation and safety features.

In our experience at Budget Heating (BudgetHeating.com), documenting lamp count, output and target dose up front avoids redesign later and keeps installations predictable.

Installation, Commissioning, Maintenance and Safety: Practical Steps for Long Term Performance

From our field installs, UV performance is reliable when roles are clear and safety is treated as part of design, not an afterthought.

- Licensed pros: size and place lamps, complete wiring and ballast work to code, commission irradiance and airflow, clean coils when needed, and handle any refrigerant or combustion system work in line with ASHRAE guidance.

- Homeowners: change filters on schedule, keep grilles clear, monitor UV status indicators, and only perform user permitted tasks with power off and proper PPE.

- Safety by design: use shielded, light tight housings, interlocks that shut lamps off when access panels open, clear warning labels, and UL or ETL listed products. Prevent eye and skin exposure, and protect nearby plastics or rubber that can degrade under UV.

- Maintenance protocol: clean lamp surfaces and quartz sleeves, verify operation after service, and replace lamps at the manufacturer interval, commonly 9 to 12 months, even if the lamp still glows. Manage mercury containing lamps per local disposal rules.

- Post install verification: test interlocks, check for any light leakage, confirm placement, and record the installation date and planned replacement date for ongoing service.

Practical Next Steps: How to Assess, Pilot and Measure UV in Your HVAC System

UV-C, properly designed and maintained, is a proven, practical add-on that suppresses growth on coils and pans and helps preserve IAQ and performance. It complements filtration, ventilation and humidity control. Outcomes are project specific: we see reports up to ~35% energy reduction, or ~15% with advanced filtration, yet installed cost, lamp replacements and payback need a site review. Next: assess the site, run a pilot or staged install, verify irradiance and safety interlocks at commissioning, fold UV into routine service, and log IAQ and energy. If you are weighing fit and budget, our U.S.-based team brings 30+ years of know-how to spec, commission and support it.

- Get a Custom Quote

- Talk to Our Team, phone support available

- Shop UV-C and IAQ Equipment, wholesale pricing, many items ship free, financing with Affirm